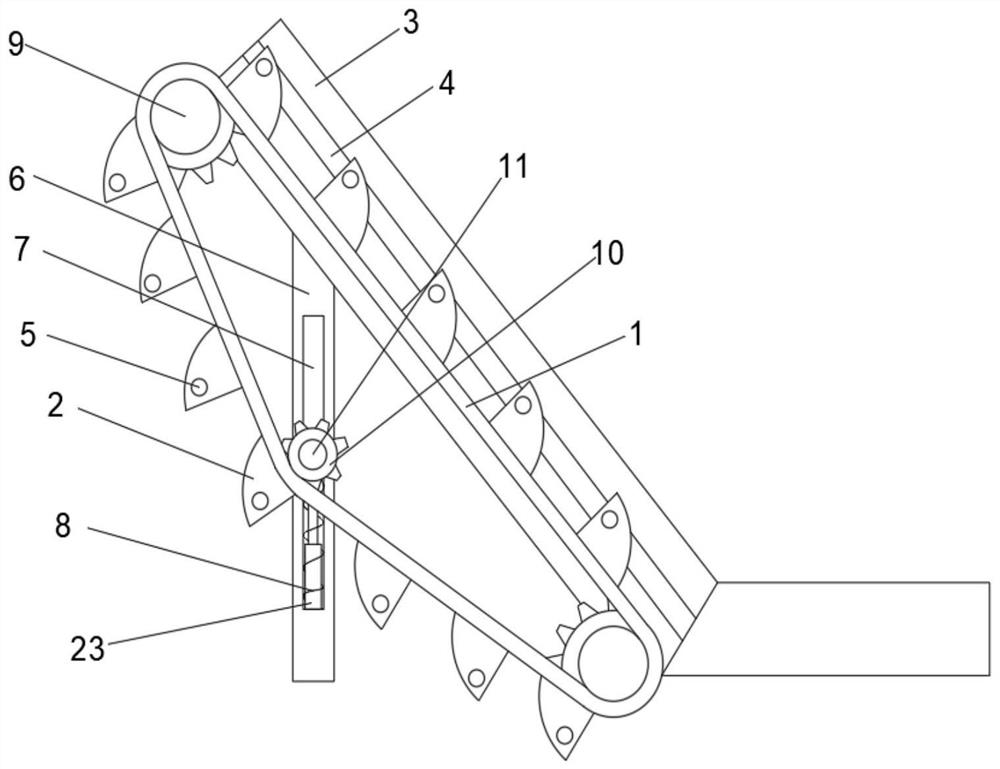

Chain bucket type elevator

A hoist and chain bucket technology, applied in the field of material transportation, can solve problems such as reduced transportation efficiency, emergency stop of machinery, scratches on hoppers, etc., and achieve the effects of improving work efficiency, improving stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

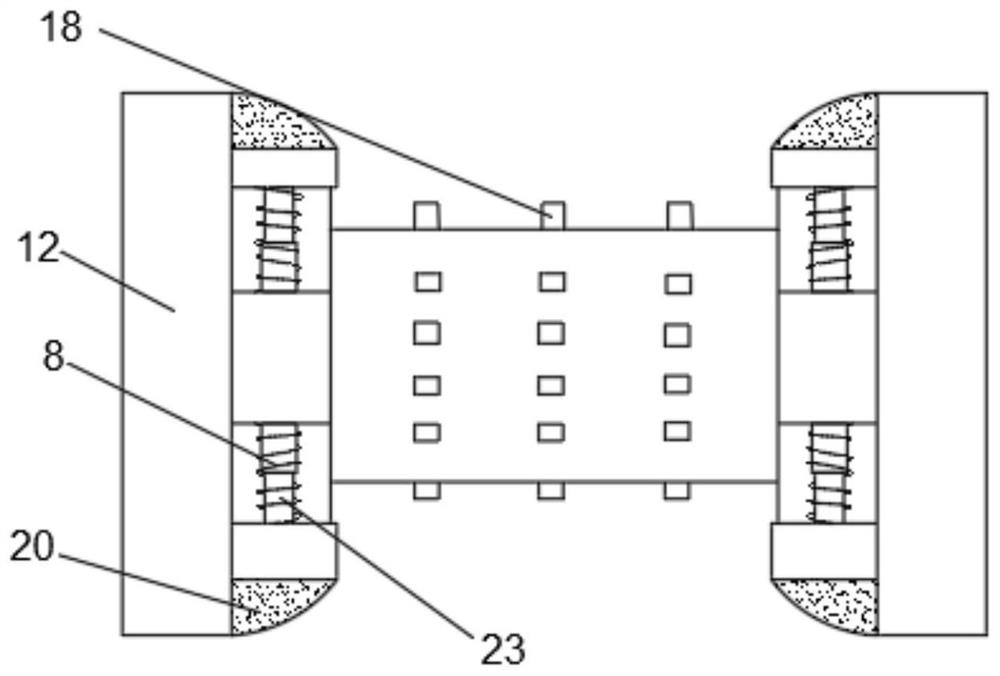

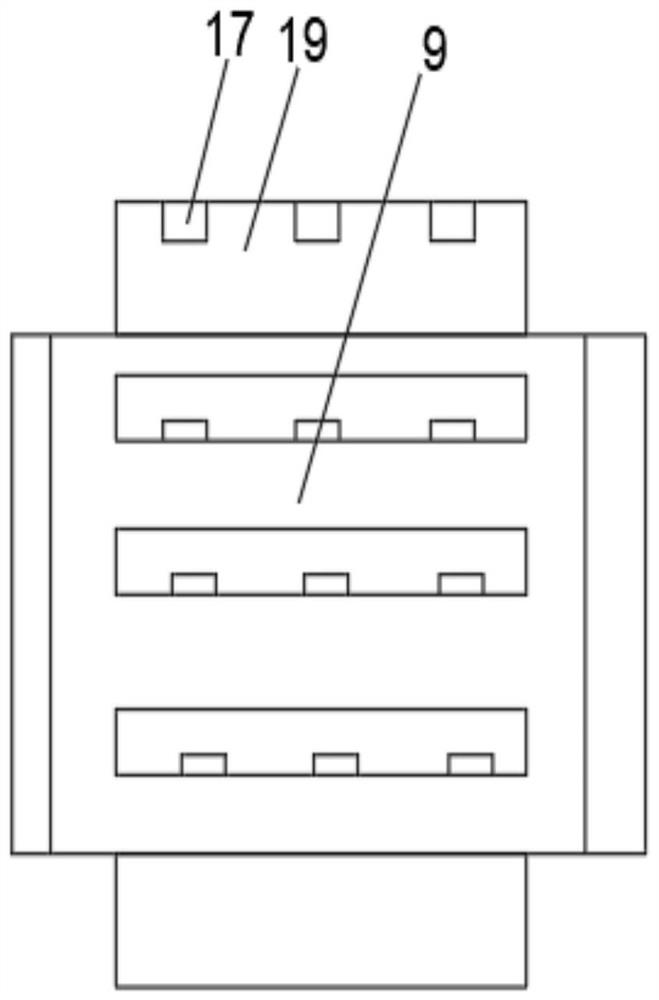

Embodiment approach

[0035] As an embodiment of the present invention, the chain 1 includes an outer link plate 21 and an inner link plate 22, and the inner link plate 22 and the outer link plate 21 are arranged at intervals, and the outer surface of one side of the inner link plate 22 rotates An adjusting rod 14 is connected, and the outer surfaces of the adjacent sides of the two outer chain plates 21 are fixedly connected with racks 13, the tooth surfaces of two adjacent racks 13 are opposite, and the adjusting rod 14 is in phase with the rack 13. Engagement, one end of the outer circular surface of the adjustment rod 14 is fixedly connected with a fixed block 16, and the connection between the inner chain plate 22 and the fixed block 16 is provided with a fixed groove 15; the chain bucket elevator transports heavier stones When using for a long time, the tightness of the connection between the inner chain plate 22 and the outer chain plate 21 on the chain 1 will be reduced. It needs to be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com