A cable releaser

A pay-off and cable technology, applied in the field of cable processing, can solve problems such as stuck, unable to pull out the cable, and no rollback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments.

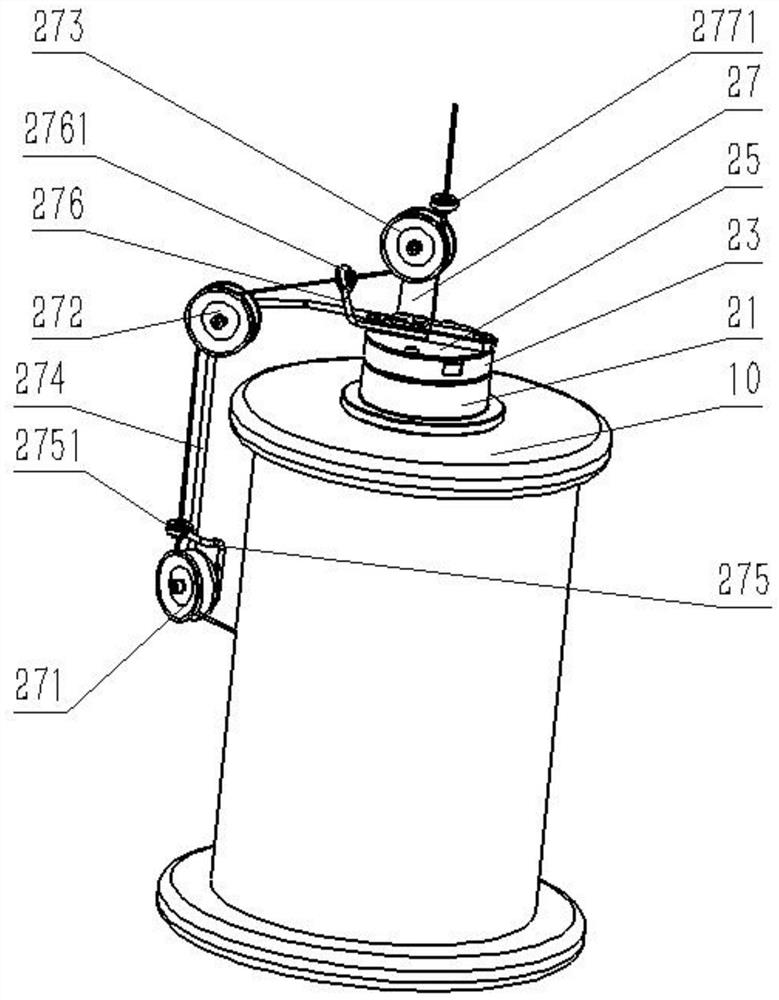

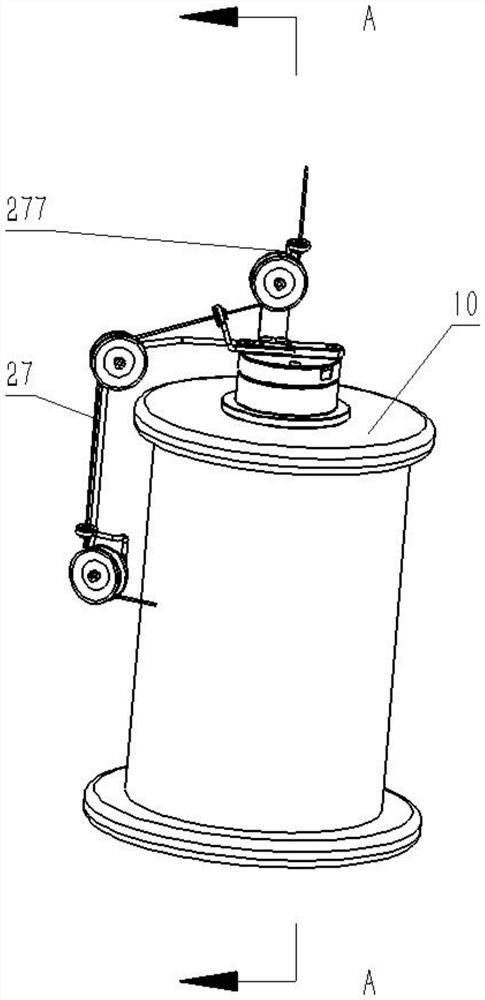

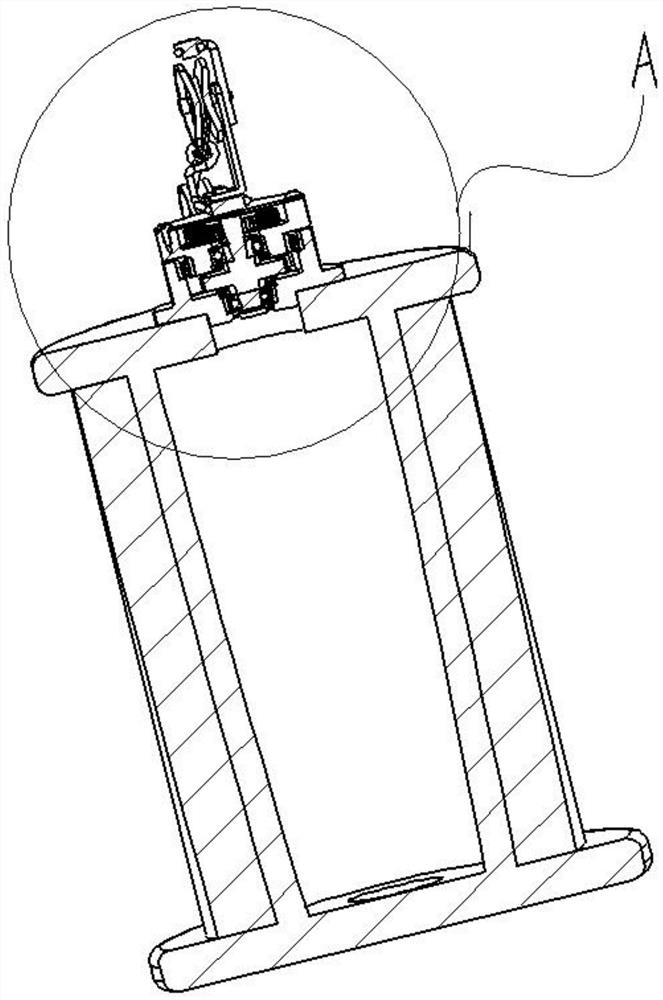

[0039] combine Figure 1-6, the present invention provides a cable pay-off device, the cable is wound on the industry standard reel 10, the center of the reel 10 is provided with a reel installation hole, including a pay-off that can be clamped and connected to the reel installation hole at the lower end The main body 21 of the pay-off device, the main body 21 of the pay-off device is an annular structure, the main body of the pay-off device 21 includes the first bearing position 211 and the second bearing position 212 arranged up and down; the central ratchet shaft 22 installed in the center of the main body 21 of the pay-off device, the central The lower end of the wheel shaft 22 is connected with the first bearing position 211 of the main body of the pay-off device through a bearing, and the central ratchet shaft 22 is provided with a ratchet 221 along the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com