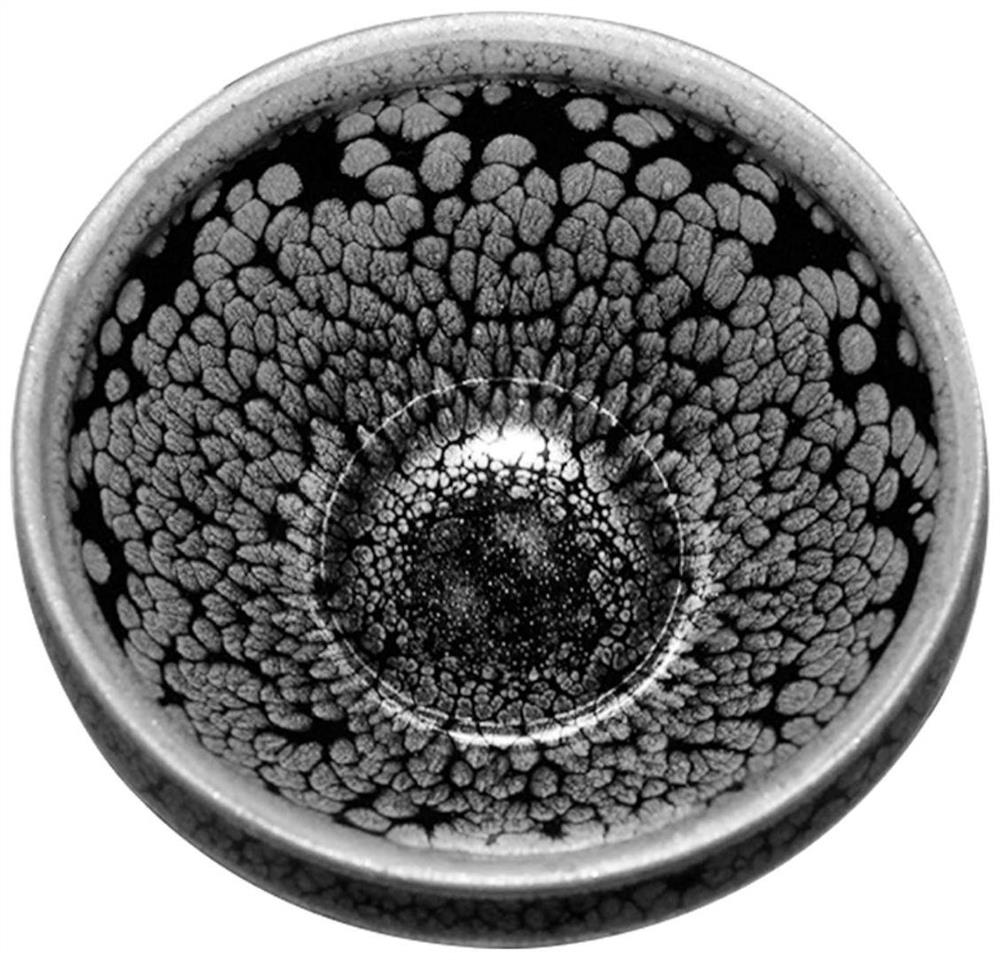

Partridge spot Jian cup manufacturing process

A production process and partridge technology, which is applied in the field of partridge-spotted lantern manufacturing technology, can solve the problems of no display of partridge-spotted crystal patterns, low yield, bubbles, etc., and achieve high artistic value and appreciation value, deformation and stability. The effect of less blistering defects and clear process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The manufacturing process of partridge spot Jianzhan includes the following steps:

[0038] (1) preparing green body and glaze slurry;

[0039] The green body is prepared by the following method: mix red clay and pear puree by equal weight, add water to wash, pass through an 80-mesh sieve, press filter, stale for 5 years, smelt, and pull the green body to form a green body, dry it, and then repair the green body Molded, dried again and bisque fired to obtain the green body;

[0040] Wherein, the laterite and pear mud are all taken from Dali Village, Shuiji Town, Jianyang District, Nanping City, Fujian Province; the Dali Mud is the mud on the mountain of Dali Village;

[0041] The biscuit firing is that the temperature of the kiln rises to 800° C. after 6 hours, and the furnace is stopped for cooling.

[0042] The glaze slurry is prepared by the following method: mix 75 parts by weight of glaze ore, 15 parts by weight of plant ash, 2 parts by weight of iron red, and 8 ...

Embodiment 2

[0057] The manufacturing process of partridge spot Jianzhan includes the following steps:

[0058] (1) preparing green body and glaze slurry;

[0059] The green body is prepared by the following method: mix red clay and pear puree by equal weight, add water to wash, pass through a 90-mesh sieve, press filter, age for 4.5 years, smelt, and pull the green body to form a green body, dry it, and then repair the green body Molded, dried again and bisque fired to obtain the green body;

[0060] Wherein, the laterite and pear mud are all taken from Dali Village, Shuiji Town, Jianyang District, Nanping City, Fujian Province; the Dali Mud is the mud on the mountain of Dali Village;

[0061] The biscuit firing is that the temperature of the kiln rises to 850° C. after 6 hours, and the furnace is stopped for cooling.

[0062] The glaze slurry is prepared by the following method: take 75 parts by weight of glaze ore, 14 parts by weight of plant ash, 1.5 parts by weight of iron red, and ...

Embodiment 3

[0075] The manufacturing process of partridge spot Jianzhan includes the following steps:

[0076] (1) preparing green body and glaze slurry;

[0077] The green body is prepared by the following method: mix red clay and pear puree by equal weight, add water to wash, pass through a 100-mesh sieve, press filter, stale for 5.5 years, smelt, and pull the green body to form a green body, dry it, and then repair the green body Molded, dried again and bisque fired to obtain the green body;

[0078] Wherein, the laterite and pear mud are all taken from Dali Village, Shuiji Town, Jianyang District, Nanping City, Fujian Province; the Dali Mud is the mud on the mountain of Dali Village;

[0079] The biscuit firing is that the temperature of the kiln rises to 820° C. after 6 hours, and the furnace is stopped for cooling.

[0080] The glaze slurry is prepared by the following method: take 75 parts by weight of glaze ore, 15 parts by weight of plant ash, 1.8 parts by weight of iron red, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com