Grouting device and grouting system

A technology of adjusting blocks and elastic parts, applied in construction, building maintenance, building construction, etc., can solve the problems of easy grout leakage, low artificial grouting efficiency, high grouting efficiency, etc., to reduce labor intensity, save manpower, and improve grouting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

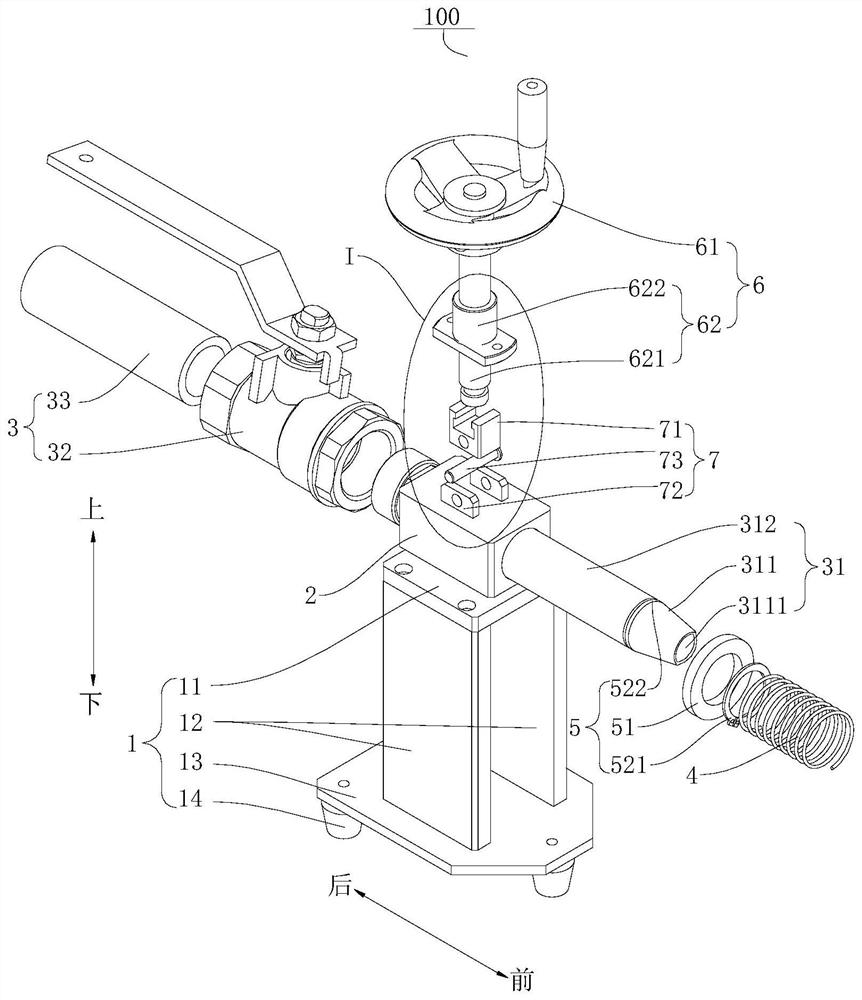

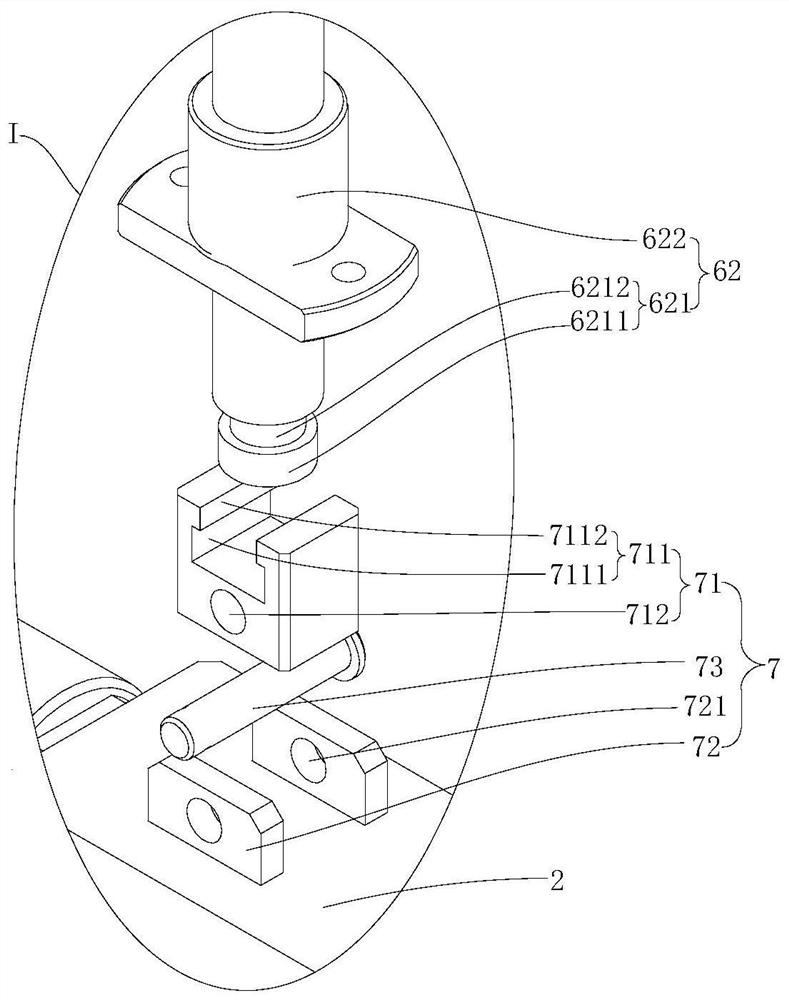

[0110] A grouting device 100, such as figure 1 As shown, it includes a bracket 1 , an adjustment block 2 , a grouting component 3 and an elastic member 4 .

[0111] Wherein, the adjusting block 2 is arranged on the support 1 in a liftable manner.

[0112] like figure 1 As shown, the grouting assembly 3 includes a grouting head 31, the grouting head 31 is slidably connected to the adjustment block 2, the side of the grouting head 31 away from the adjustment block 2 is provided with a limiting part 5, and the limiting part 5 has The locking position on the grouting head 31.

[0113] The elastic piece 4 is arranged between the limiting part 5 and the adjusting block 2, and when the elastic piece 4 drives the limiting part 5 to the locking position, the elastic piece 4 drives the grouting head 31 to move towards the grouting direction.

Embodiment 2

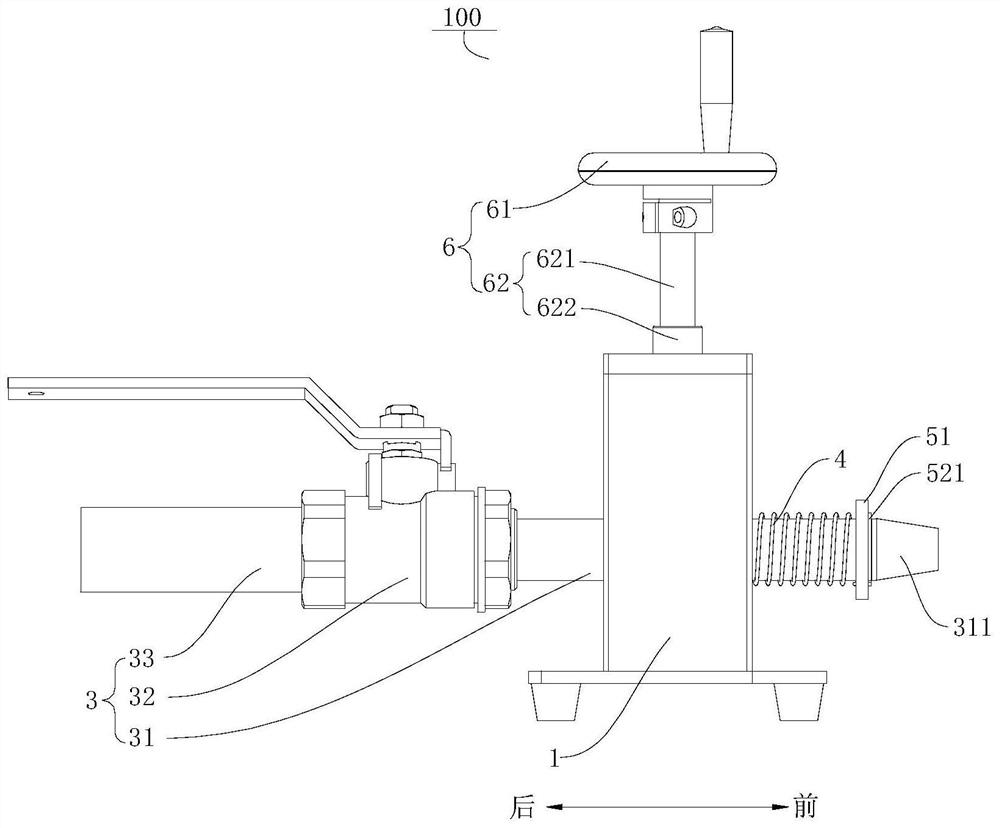

[0115] A grouting device 100, different from Embodiment 1, on the basis of Embodiment 1, such as Figure 5As shown, the limiting portion 5 includes a limiting ring 51 , and a stopping portion 52 is provided at the locking position. When the stretching length of the elastic member 4 is at a maximum, the limiting ring 51 is limited at the stopping portion 52 . The elastic member 4 is a spring, one end of the spring is connected with the limit ring 51 to move the support 1 when the elastic member 4 shrinks, and the other end of the spring is in contact with the adjustment block 2 .

Embodiment 3

[0117] A grouting device 100, different from Embodiment 2, on the basis of Embodiment 2, such as figure 1 As shown, the grouting head 31 includes a tapered portion 311 and an equal-diameter portion 312. One end of the equal-diameter portion 312 is connected to the tapered portion 311, and the end of the tapered portion 311 away from the equal-diameter portion 312 forms a grouting port 3111. A stop portion 52 is formed at the junction with the equal-diameter portion 312 , and the stop portion 52 protrudes from the surface of the grout head.

[0118] like Figure 5 As shown, the stop portion 52 includes a stop groove 522 and a clip 521, the clip 521 is detachably connected in the stop portion 52, one end surface of the stop ring 51 is abutted against the clip 521, and the stop ring 51 The other end surface is connected with the elastic member 4 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap