Feed granulator

A granulator and feed technology, applied in the direction of feed, solid separation, filter and sieve, etc., can solve the problems of single function, troublesome, unable to sieve feed particles, etc., and achieve the effect of strong practicability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

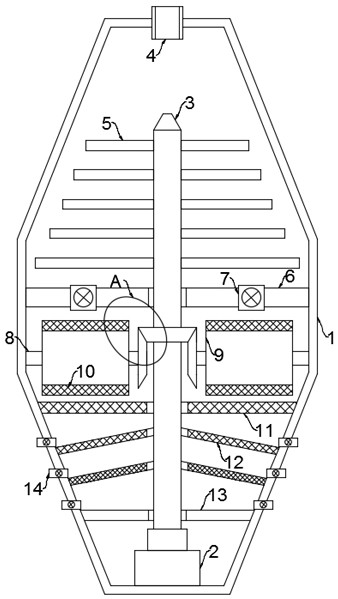

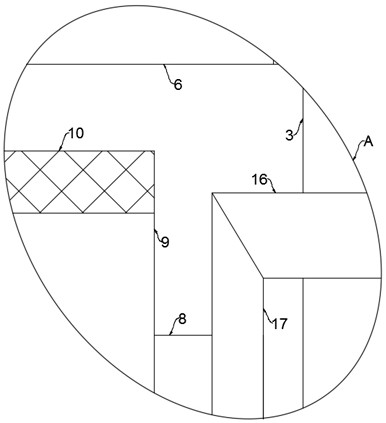

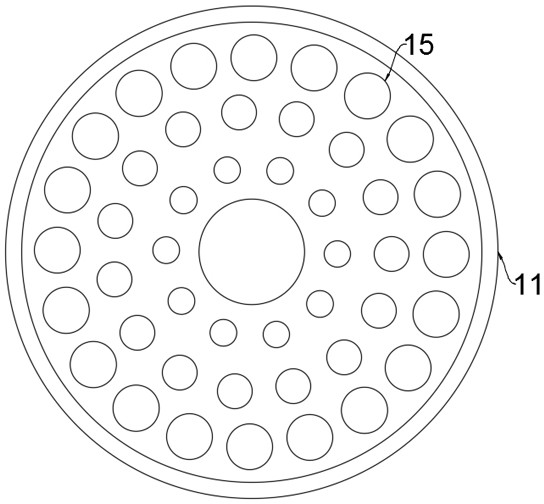

[0017] refer to Figure 1-3 , a kind of feed granulator, comprises the main body 1 that is communicated with feed pipe 4, and motor 2, partition plate 6, baffle plate 13, granulation plate 11, two screening nets 12, two A plurality of screening holes are provided on the screening net 12, and the aperture of the screening aperture positioned at the upper part is smaller than that of the lower screening aperture, and a plurality of breaking rods 5 are fixedly installed on the driving end of the motor 2 through the rotating roller 3 , two pressure cylinders 9 are installed between the main body 1 and the rotating roller 3 through a rotating mechanism, a plurality of discharge pipes 7 are communicated on the partition plate 6, and a plurality of discharge pipes 14 are communicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com