Seed and peel separator

A seed coat separation and separation mechanism technology, which is applied in the field of seed coat separators, can solve the problems of frequent manual drying, low overall efficiency, complicated procedures, etc., so as to improve the separation efficiency and separation effect, realize automatic production, and improve the separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

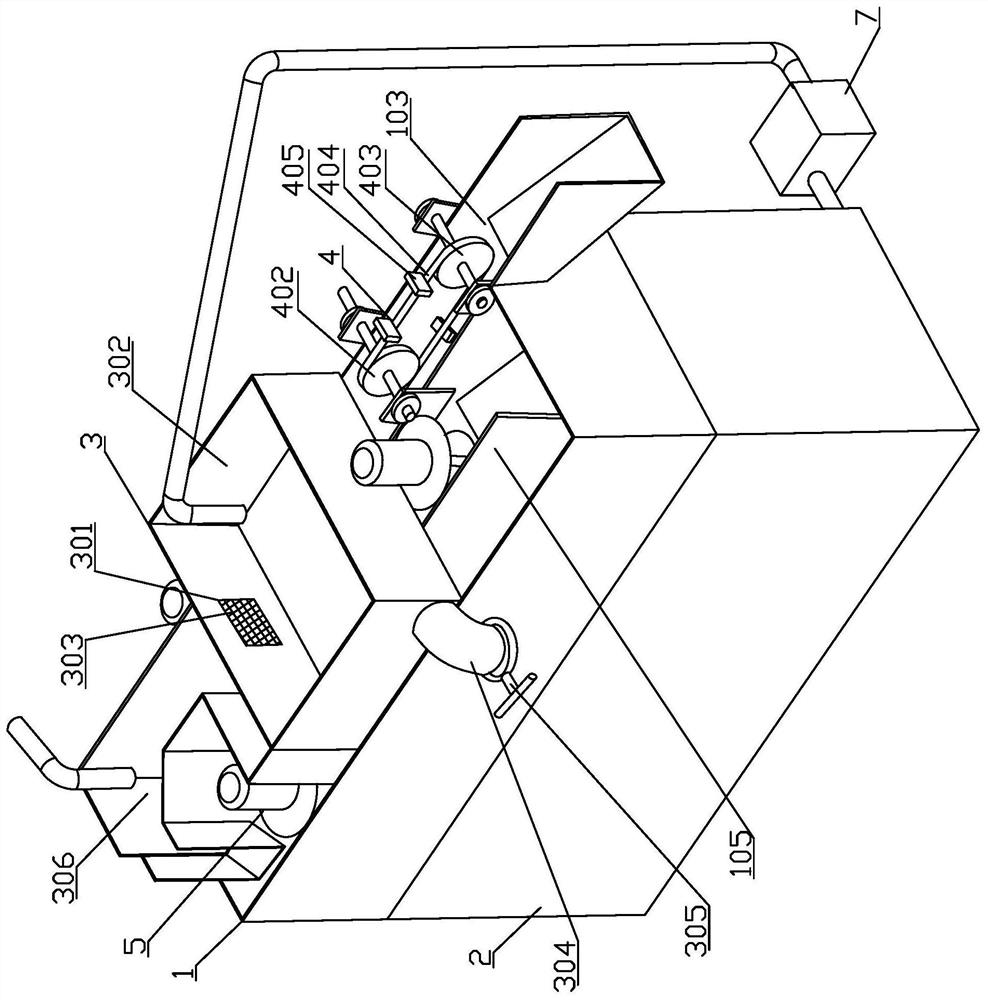

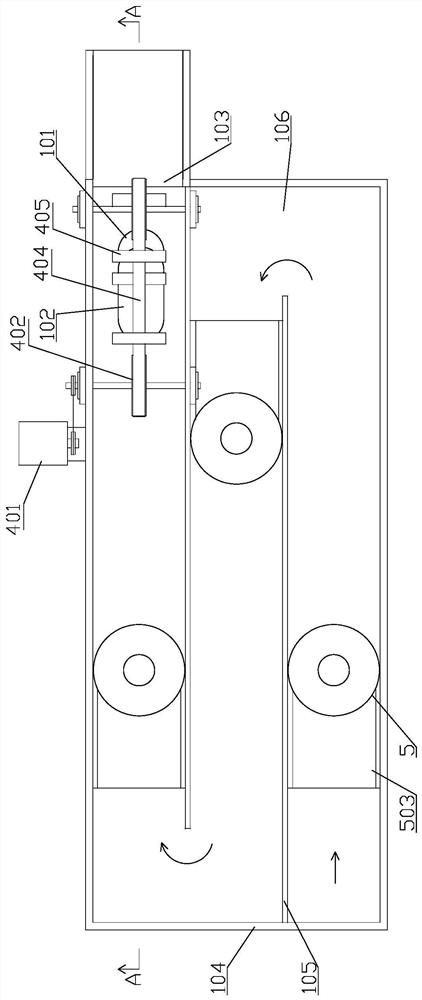

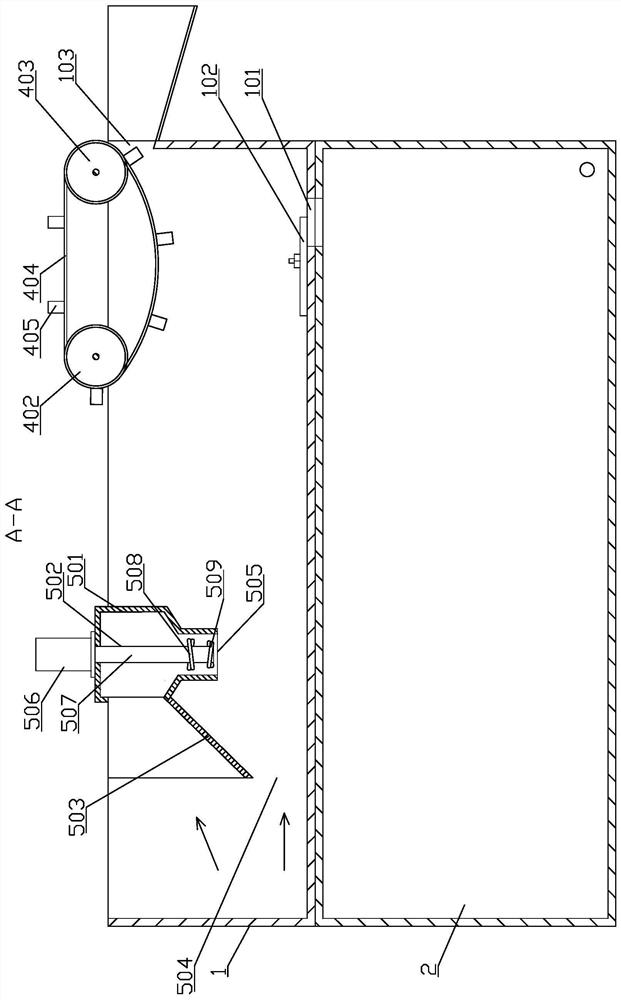

[0020] Embodiment 1: as Figure 1 to Figure 3 As shown, the seed skin separator includes a stirring tank 1, a buffer tank 2, a seed separation mechanism 3 and a skin separation mechanism 4. The stirring tank 1 includes a tank body 104, and inside the tank body 104 are vertically provided with several horizontally staggered Partition plate 105, several partition plates 105 divide the interior of the tank body 104 into serpentine passage 106; one end of serpentine passage 106 is the inlet end, and the other end of the serpentine passage 106 is the outlet end; seed skin mixture and water are added from the inlet end The slurry is formed in the stirring tank 1, and the slurry flows along the serpentine channel 106, and finally reaches the outlet end; inside the stirring tank 1, a number of stirring mechanisms 5 are sequentially arranged along the material flow direction, and the stirring mechanism 5 is used for the stirring tank 1 The slurry inside is stirred repeatedly to separat...

Embodiment 2

[0027] Embodiment 2: its overall structure is identical with embodiment 1, and difference is, as Figure 4 with Figure 5 As shown, a replenishing water tank 8 is fixed on the side of the stirring tank 1, a replenishing water filter screen 9 is arranged on the side wall between the replenishing water tank 8 and the stirring tank 1, and a water level controller 10 is arranged inside the replenishing water tank 8. The side of the replenishment tank 8 is communicated with a replenishment pipe 11, the outer end of the replenishment pipe 11 communicates with the water source, and a replenishment control valve 12 electrically connected to the water level controller 10 is installed on the replenishment pipe 11; between the stirring tank 1 and the replenishment tank 8 The connection is realized through the water supply filter 9 to keep the water level consistent, and at the same time the water supply filter 9 can block the seed skins in the mixing tank 1 to prevent them from entering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com