Preparation method and preparation equipment of QS-2 retarding superplasticizer

A high-efficiency water-reducing agent, QS-2 technology, applied in the field of water-reducing agent production, can solve the problems affecting the performance of water-reducing agent, uneven mixing, etc., to achieve increased water-reducing rate, increased retardation time, and strong sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

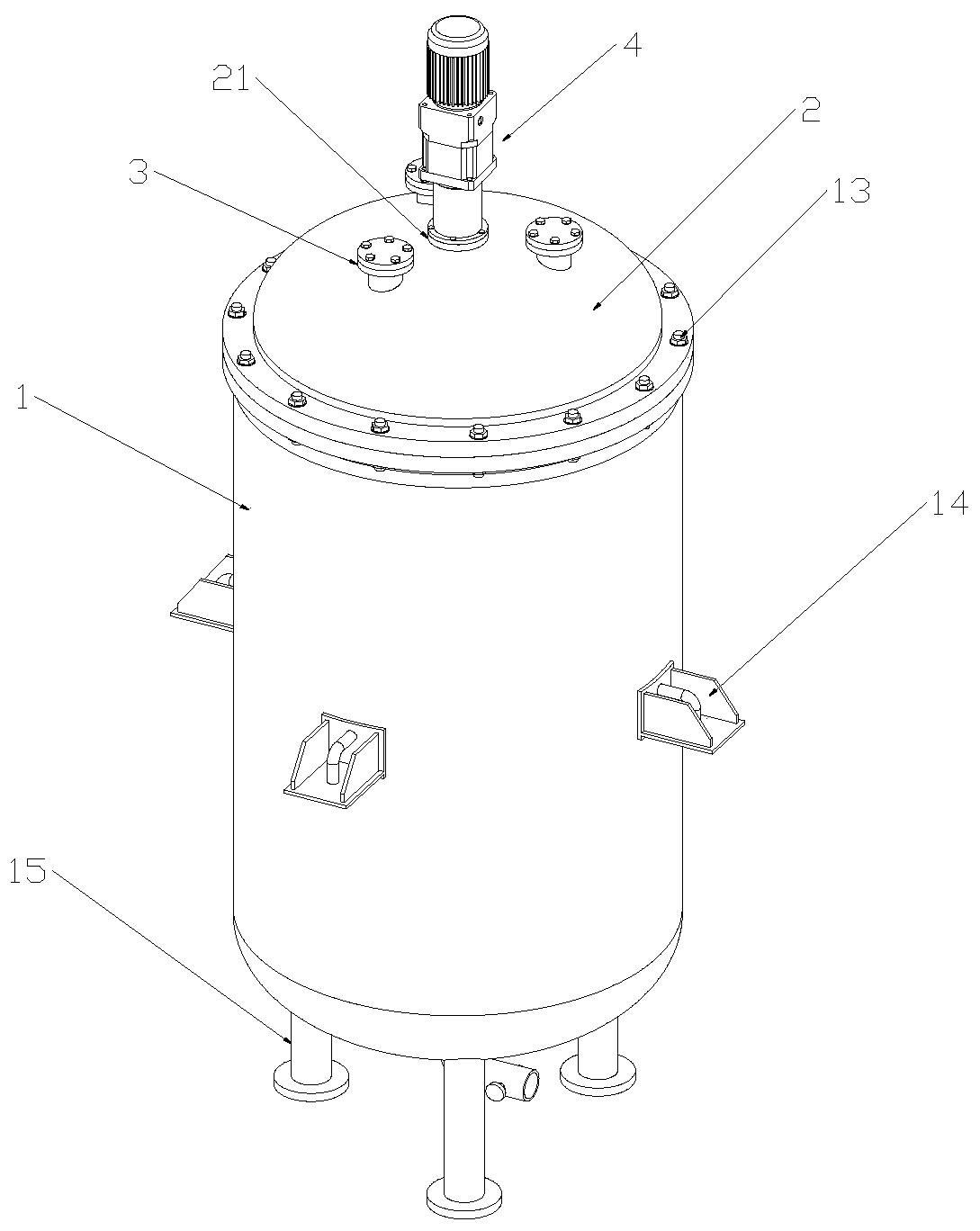

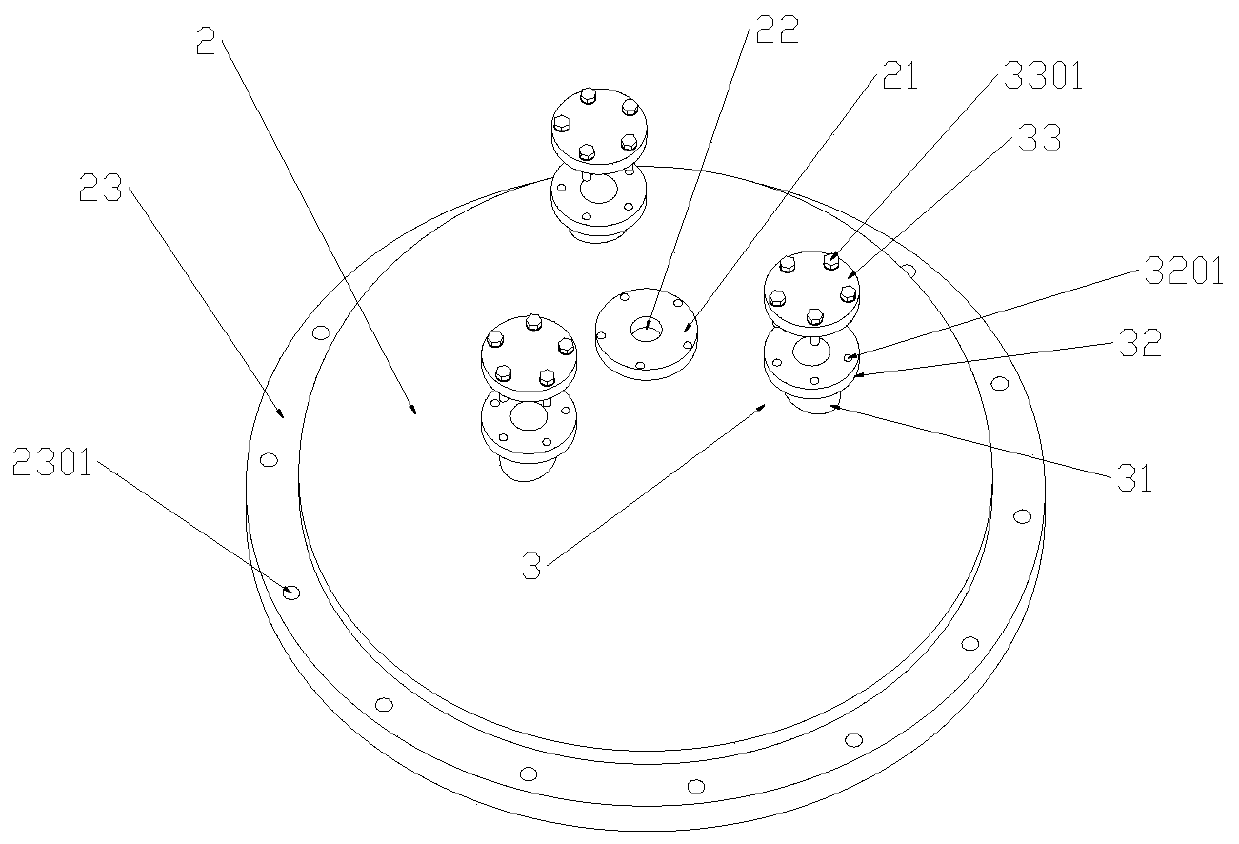

[0050] A kind of preparation method of QS-2 retarding high-efficiency water reducing agent, the preparation method of described water reducing agent comprises the following steps:

[0051] 1. Selection of raw materials

[0052] Choose 88 kilograms of aliphatic mother liquors, 0.5 kilograms of sodium gluconate, 0.5 kilograms of maltodextrin, 0.2 kilograms of rosin, and 7.4 kilograms of water, wherein 88 kilograms of aliphatic mother liquors are equally divided into two parts, A and B, for subsequent use;

[0053] 2. Stirring for the first time

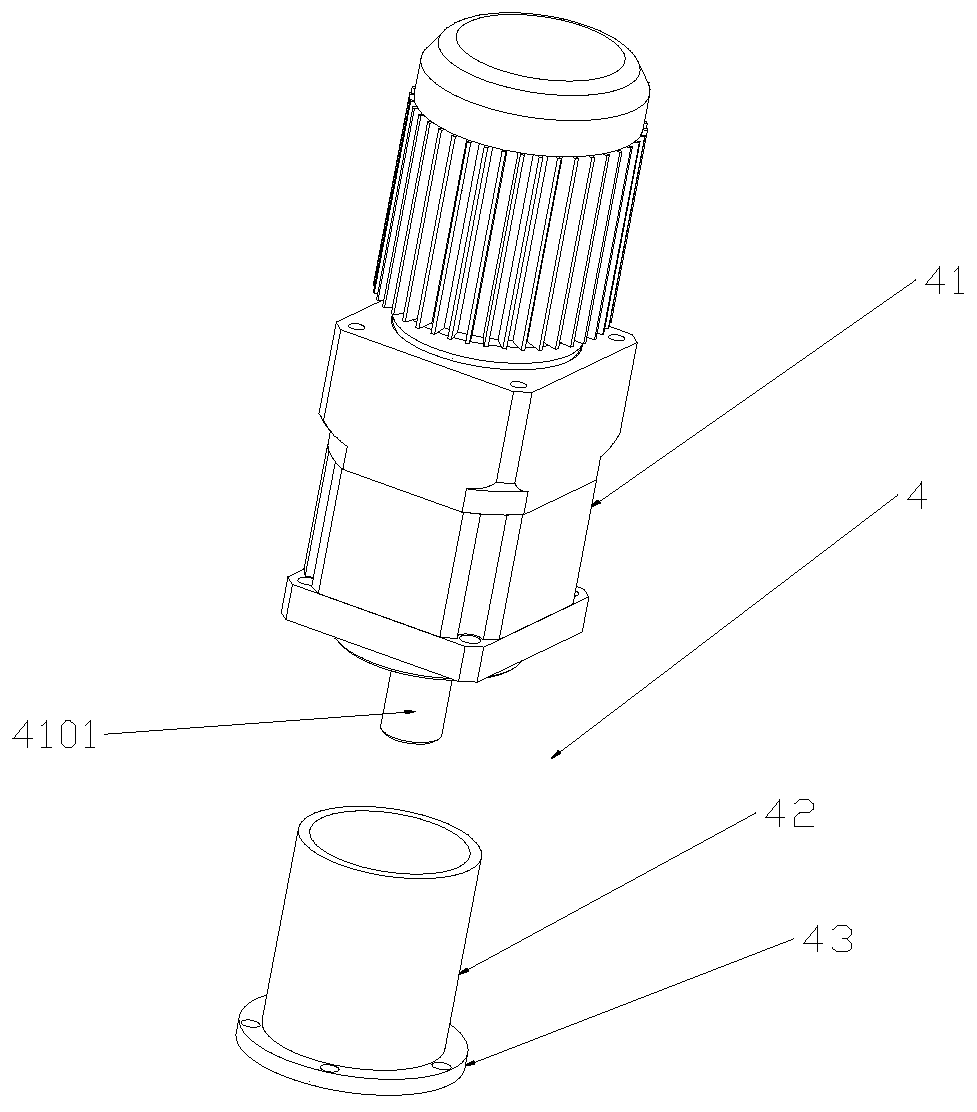

[0054]Add the water in step 1 into the preparation equipment, turn on the preparation equipment, add part A of aliphatic mother liquor into the preparation equipment at a constant speed, the addition speed is 800ml / min, stir at a constant speed for 1-2 hours, and the rotation speed is 20-30r / min, until The aliphatic mother liquor and water are completely mixed to obtain a mixed liquor;

[0055] Third, the second stirring

[0056] Add...

Embodiment 2

[0060] A kind of preparation method of QS-2 retarding high-efficiency water reducing agent, the preparation method of described water reducing agent comprises the following steps:

[0061] 1. Selection of raw materials

[0062] Choose 90 kilograms of aliphatic mother liquor, 1 kilogram of sodium gluconate, 1 kilogram of maltodextrin, 0.3 kilogram of rosin, 7.7 kilograms of water, wherein 90 kilograms of aliphatic mother liquor are equally divided into two parts, A and B, for subsequent use;

[0063] 2. Stirring for the first time

[0064] Add the water in step 1 into the preparation equipment, turn on the preparation equipment, add part A of aliphatic mother liquor into the preparation equipment at a constant speed, the addition speed is 800ml / min, stir at a constant speed for 1-2 hours, and the rotation speed is 20-30r / min, until The aliphatic mother liquor and water are completely mixed to obtain a mixed liquor;

[0065] Third, the second stirring

[0066] Add sodium gluc...

Embodiment 3

[0070] A kind of preparation method of QS-2 retarding high-efficiency water reducing agent, the preparation method of described water reducing agent comprises the following steps:

[0071] 1. Selection of raw materials

[0072] Choose 92 kilograms of aliphatic mother liquors, 1.5 kilograms of sodium gluconate, 1.5 kilograms of maltodextrins, 0.7 kilograms of rosin, and 8.0 kilograms of water, wherein 92 kilograms of aliphatic mother liquors are equally divided into two parts, A and B, for subsequent use;

[0073] 2. Stirring for the first time

[0074] Add the water in step 1 into the preparation equipment, turn on the preparation equipment, add part A of aliphatic mother liquor into the preparation equipment at a constant speed, the addition speed is 800ml / min, stir at a constant speed for 1-2 hours, and the rotation speed is 20-30r / min, until The aliphatic mother liquor and water are completely mixed to obtain a mixed liquor;

[0075] Third, the second stirring

[0076] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com