Mixing device for rare earth powder

A technology of mixing device and rare earth powder, which is applied in the field of mixing device, can solve the problems of high work intensity, acid fatigue after changing hands, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

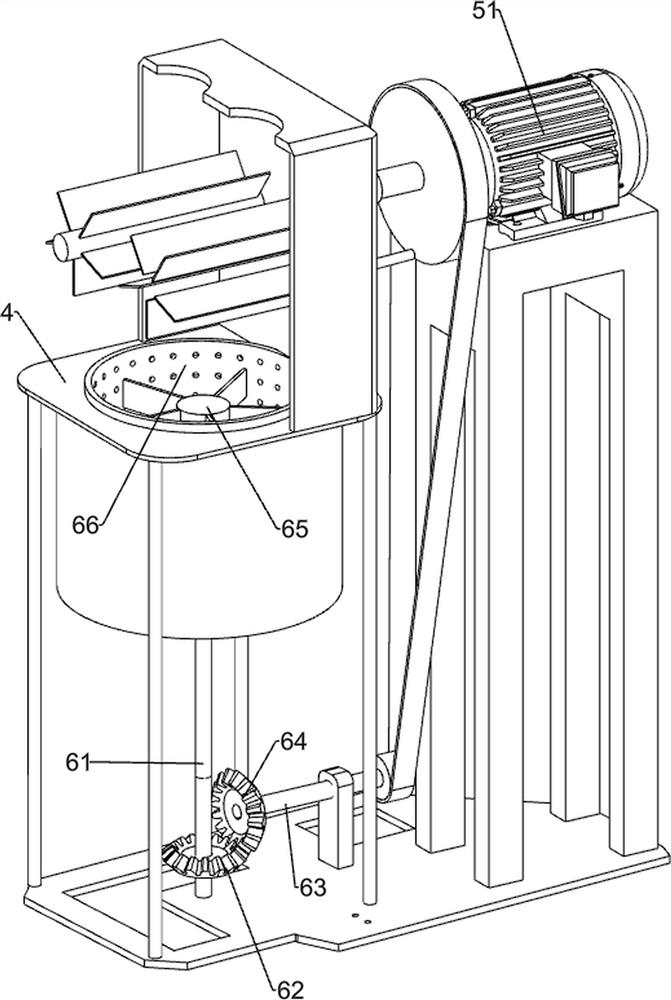

[0025] A mixing device for rare earth powder, such as Figure 1-3 As shown, it includes a placement board 1, a support rod 2, a base 3, a blanking frame 4, a drive assembly 5, and a stirring assembly 6. The top left side of the placement board 1 is connected to the support rod 2, and the top right side of the placement board 1 is connected to the base. 3. A blanking frame 4 is connected to the top of the pole 2, a driving component 5 is connected to the top of the base 3, and a stirring component 6 is connected to the top of the placing plate 1 in a rotating manner on the left side.

[0026] The driving assembly 5 includes a motor 51, a first gear 52, a first stirring rod 53, a second gear 54, a second stirring rod 55, a first rotating shaft 56 and a third gear 57, and a motor 51 is installed on the top of the base 3, and the motor 51 The output shaft is connected with a first gear 52, the right end of the blanking frame 4 is connected with a first stirring rod 53 in a rotatin...

Embodiment 2

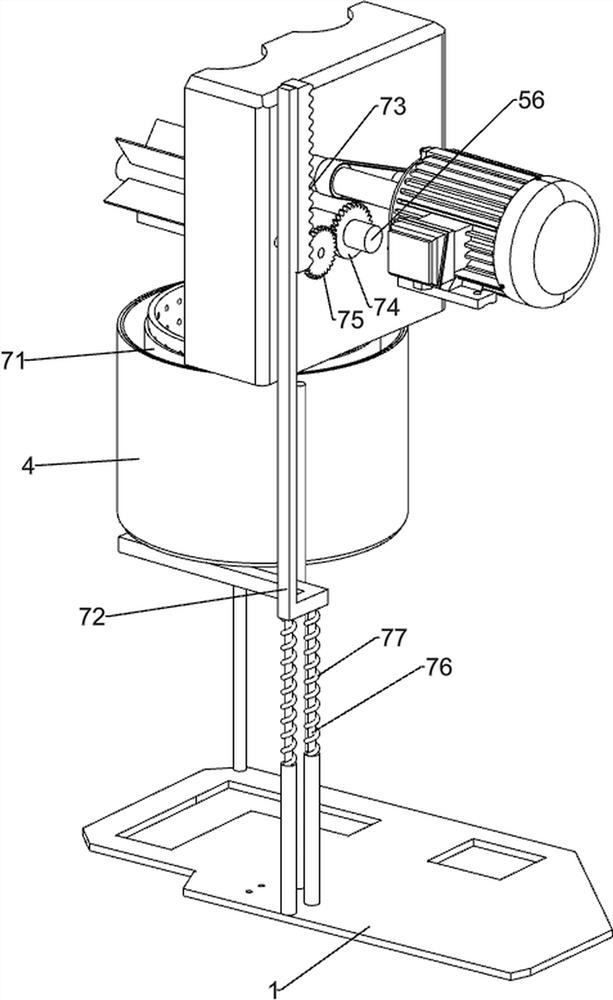

[0030] On the basis of Example 1, such as Figure 4 Shown, also include collection assembly 7, collection assembly 7 includes collection box 71, bent bar 72, rack 73, missing gear 74, the 4th gear 75, slide bar 76 and back-moving spring 77, blanking frame 4 inner bottom A collection box 71 is slidably connected, the inside of the collection box 71 is in contact with the outside of the screen box 66, the bottom of the front side of the collection box 71 is connected with a curved bar 72, the top of the curved bar 72 is connected with a rack 73, and the right side of the first rotating shaft 56 is connected with a gap. Gear 74, the upper right end of the blanking frame 4 is rotatably connected with a fourth gear 75, the fourth gear 75 is meshed with the missing gear 74, the bottom right side of the curved bar 72 is connected with a slide bar 76, and the slide bar 76 is slidable with the placement plate 1 To connect, a return spring 77 is sleeved between the bottom of the curved ...

Embodiment 3

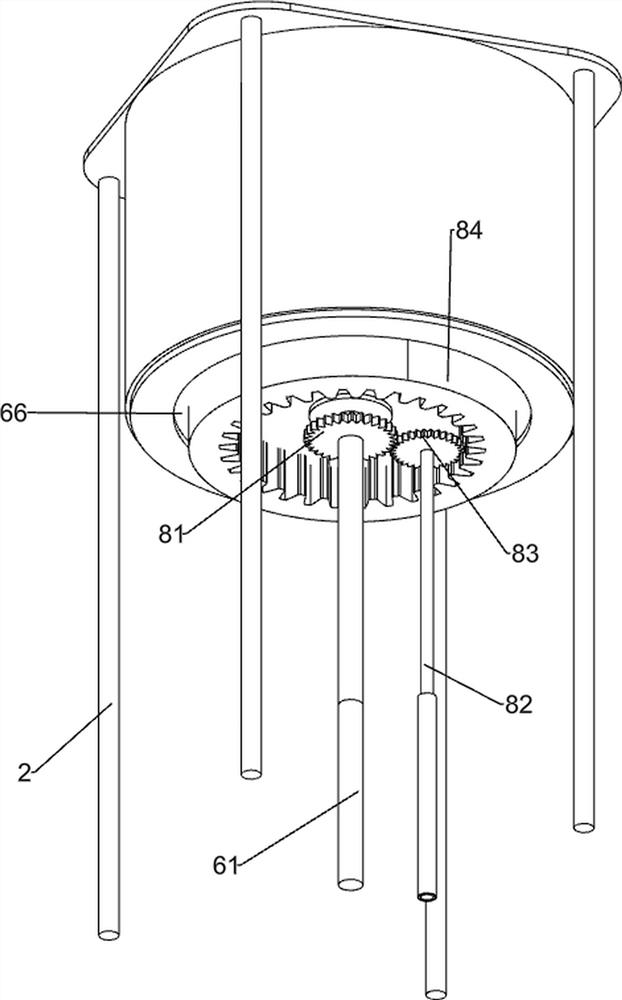

[0033] On the basis of Example 2, such as Figure 5 As shown, a rotating assembly 8 is also included. The rotating assembly 8 includes a fifth gear 81, a fourth rotating shaft 82, a sixth gear 83 and an internal gear 84. The upper part of the second rotating shaft 61 is connected with the fifth gear 81, and the bottom of the plate 1 is placed The left side rotation type is connected with the fourth shaft 82, the top of the fourth shaft 82 is connected with the sixth gear 83, the sixth gear 83 is meshed with the fifth gear 81, the bottom of the screen box 66 is connected with the internal gear 84, the internal gear 84 is connected with the fifth gear 81 The six gears 83 are meshed.

[0034] When the second shaft 61 rotates, the rotation of the second shaft 61 drives the fifth gear 81 to rotate, the rotation of the fifth gear 81 drives the rotation of the sixth gear 83, the rotation of the sixth gear 83 drives the rotation of the internal gear 84, and the rotation of the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com