Shakeout machine for sand mold casting

A technology of sand casting and shakeout machine, applied in the field of sand casting, can solve the problems of no shock absorption mechanism, low efficiency, shortened service life of the device, etc., to save time, improve the efficiency of falling sand, and reduce vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

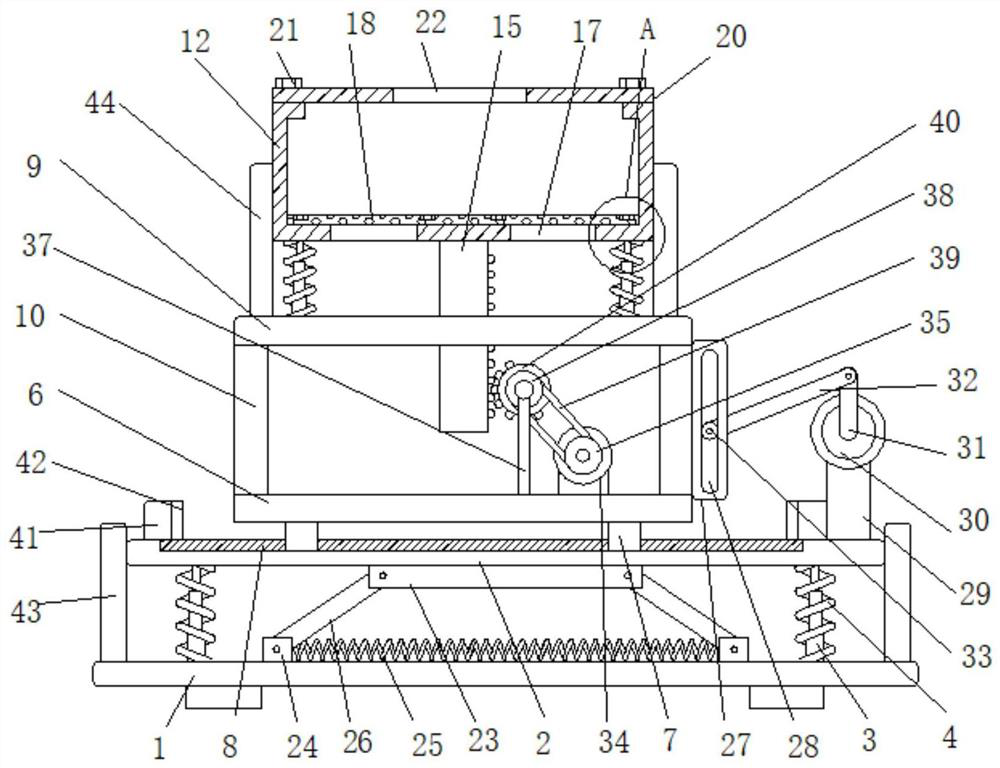

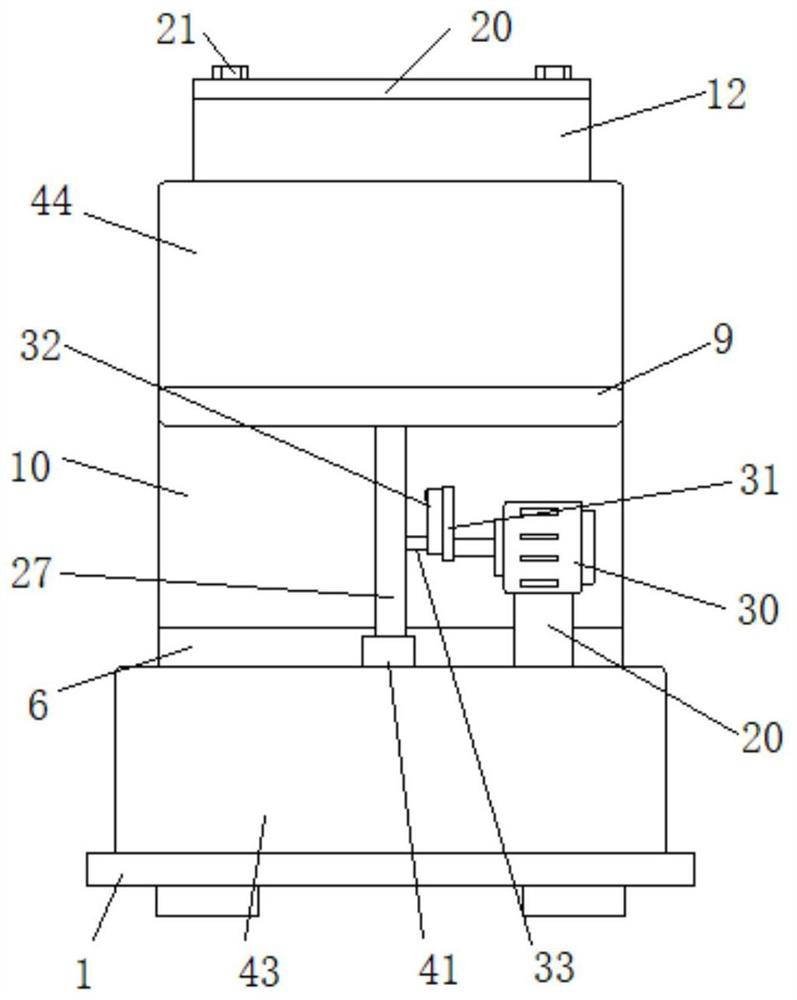

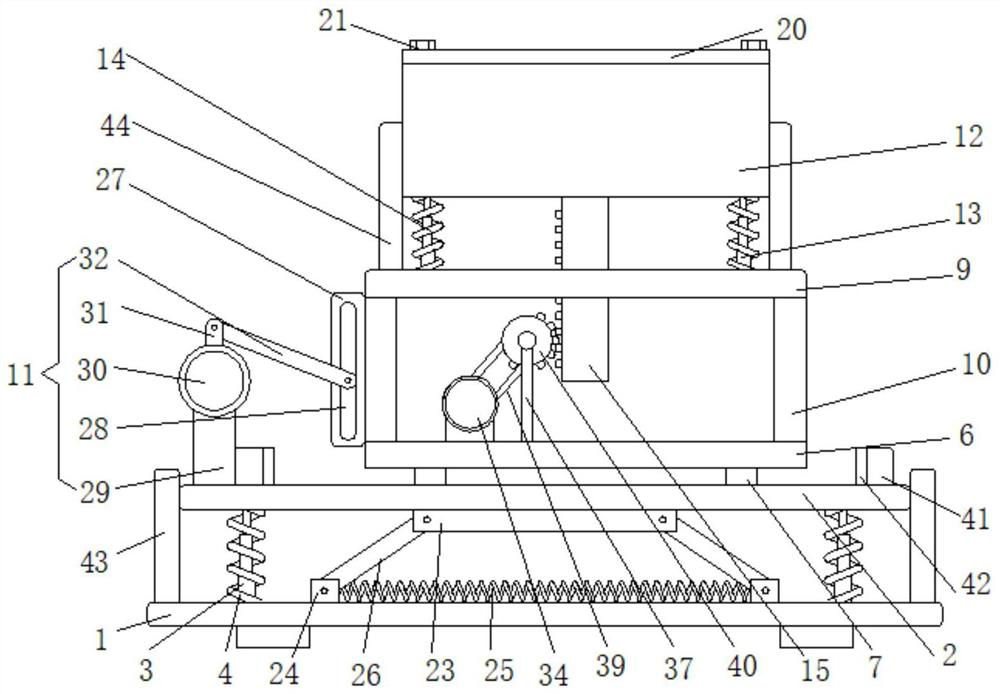

[0031] Embodiment one, such as Figure 1-7As shown, a shakeout machine for sand casting includes a first base plate 1 arranged horizontally, a second base plate 2 is arranged horizontally above the first base plate 1, and the second base plate 2 passes through a plurality of first telescopic rods 3 vertically arranged It is fixedly connected with the first base plate 1, and the second base plate 2 is fixedly connected with the first base plate 1 through a plurality of vertically arranged first springs 4, and the plurality of first springs 4 are respectively wound on the corresponding first telescopic rods 3. A damping mechanism 5 is provided between the first base plate 1 and the second base plate 2, and a first fixed plate 6 is horizontally arranged above the second base plate 2, and a plurality of sliders 7 are fixedly connected to the bottom surface of the first fixed plate 6, and the second base plate 2 The upper surface is provided with a chute 8, the chute 8 is slidably ...

Embodiment 2

[0032] Embodiment two, such as figure 1 , 3 , 6, the damping mechanism 5 includes a damping plate 23 fixedly connected to the bottom surface of the second base plate 2, the damping plate 23 is horizontally arranged, and the upper surface of the first base plate 1 is slidingly connected with two damping blocks 24, two damping blocks 24 The shock block 24 is fixedly connected by a plurality of third springs 25 arranged horizontally, and both ends of the shock absorbing plate 23 are rotatably connected with first connecting rods 26, and the ends of the two first connecting rods 26 far away from the shock absorbing plate 23 are connected to the same side respectively. The corresponding damping block 24 is rotationally connected, and the vertical force is decomposed into the driving force of the shock absorbing block 24 in the horizontal direction through the first connecting rod when the second bottom plate 2 vibrates up and down by setting the shock absorbing plate 23. Then the ...

Embodiment 3

[0033] Embodiment three, such as Figure 1-4 As shown, the horizontal vibration mechanism 11 includes an engaging plate 27 fixedly connected to the outside of the support plate 10, the engaging plate 27 is vertically arranged, a slot 28 is vertically arranged on the engaging plate 27, and a base is fixedly connected to the upper surface of the second bottom plate 2 29, the base 29 and the connecting plate 27 are located on the same side, the top of the base 29 is fixedly connected to the first motor 30, the shaft of the first motor 30 is fixedly connected to the second connecting rod 31, and the second connecting rod 31 is far away from the axis of the first motor 30 One end is rotatably connected with a third connecting rod 32, the end of the third connecting rod 32 away from the second connecting rod 31 is rotatably connected with a first rotating shaft 33, the first rotating shaft 33 is embedded in the slot 28 and is rotatably connected with it, the second connecting rod Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com