Cutting workbench for waste steel recycling

A technology of recycling and working table, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that affect the normal cutting work, the danger of the staff, and the unstable clamping, so as to avoid shaking or even falling. Falling, ensuring safety, and stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

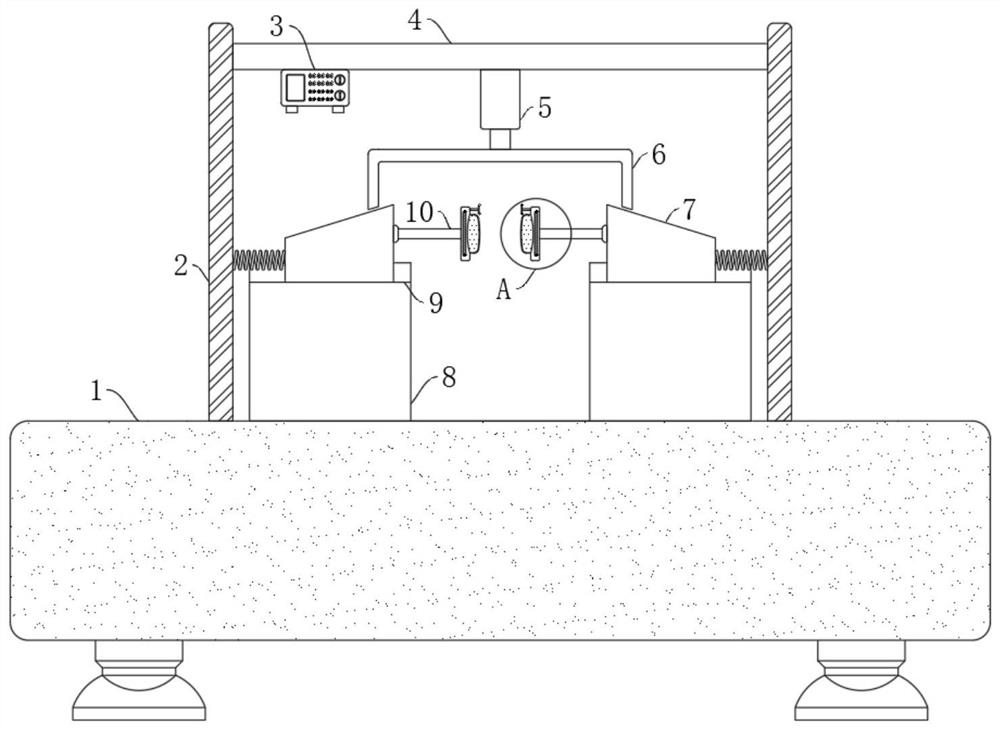

[0025] refer to Figure 1-2 , a cutting workbench for scrap steel recycling, comprising a cutting table 1, two support plates 2 fixedly connected to the upper wall of the cutting table 1, two placement seats 8 fixedly connected to the upper wall of the cutting table 1, two support plates 2 The opposite side walls are jointly fixedly connected with a top plate 4 .

[0026] The upper end of the cutting table 1 is provided with a clamping mechanism for clamping steel materials. The clamping mechanism includes two placement grooves 9 arranged on two placement seats 8, and a moving seat 7 is slidably connected in the two placement grooves 9. The side walls of the mobile seat 7 are elastically connected with the side walls of the support plate 2 by extension springs, and the upper side walls of the two mobile seats 7 are provided with inclined surfaces, and the side walls of the two mobile seats 7 are respectively fitted with the two placement grooves 9 inner walls to ensure The mo...

Embodiment 2

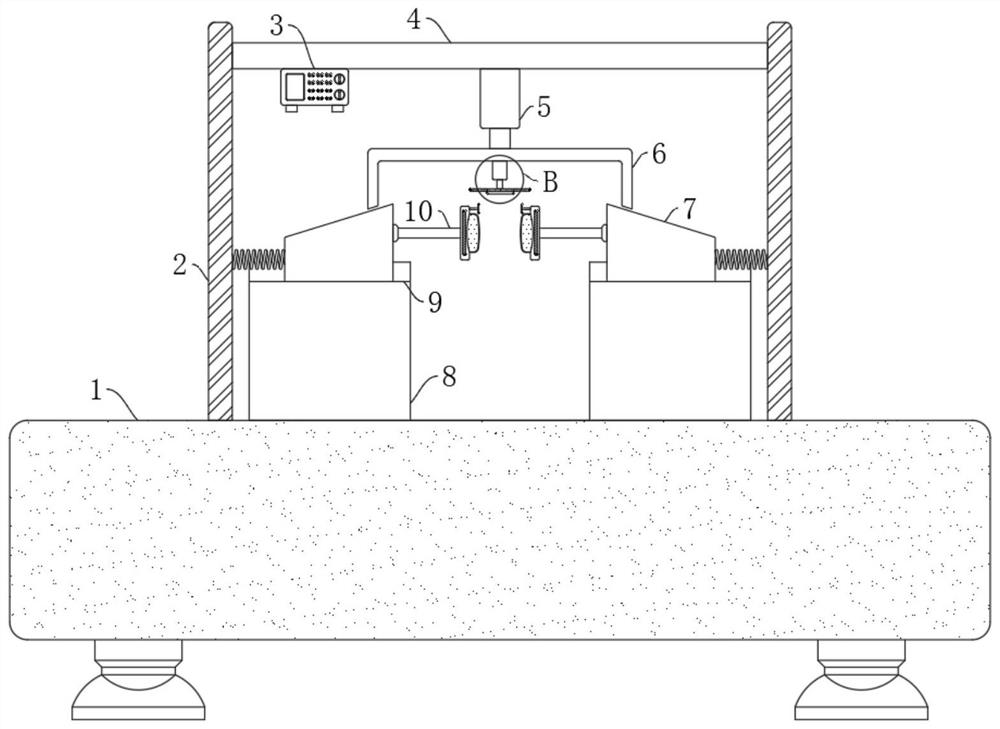

[0031] refer to Figure 3-4 , a cutting workbench for waste steel recycling and processing, the lower side wall of the push rod 6 is fixedly connected with an electric telescopic rod 17, the telescopic end of the electric telescopic rod 17 is fixedly connected with a moving plate 18, and the lower side wall of the moving plate 18 is fixedly connected with a connecting rod. electric board19.

[0032] In embodiment 1, when steel is clamped, two contact plates 16 must be made to contact so that the two electromagnetic plates 12 can be energized to have a better clamping effect. Therefore, embodiment 1 is suitable for clamping more Small or thinner steel, compared with Embodiment 1, in this embodiment, when clamping larger or thicker steel, when the two elastic bladders 13 are deformed to the maximum extent, the two contact pieces 16 still have no Contact each other, at this moment, can start electric telescopic link 17, make electric telescopic link 17 extend, drive mobile plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com