Rotating disc type intelligent assembling equipment for faucet inverted screw O-shaped ring

A technology for assembling equipment and faucets, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of time-consuming and laborious assembly, and achieve the effect of reducing human labor and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following description is used to disclose the invention to enable those skilled in the art. Preferred embodiments in the following description are only example, and those skilled in the art can think of other obvious variations.

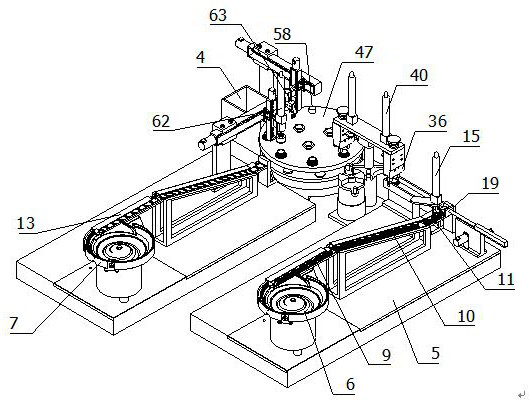

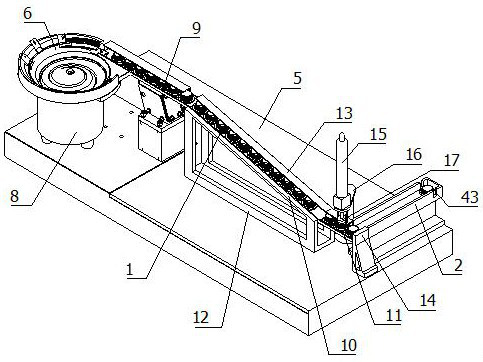

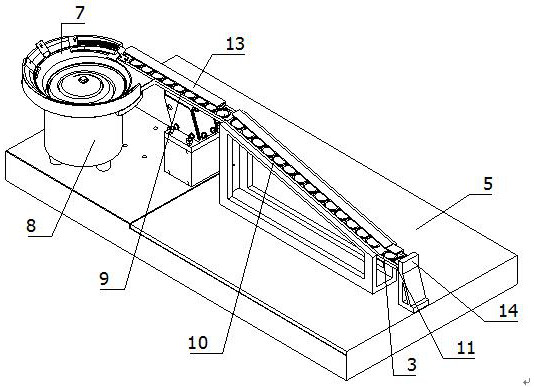

[0031] Refer Figures 1 to 10 As shown, a turntable intelligent assembly apparatus for the faucet retrore O-ring, including the first sheet assembly for the faucet retrofold 1, Pirant 2, for the faucet retrore 1 from the above The component pushes to the push assembly on the pusup 2, the rotating assembly for rotating the feed, is used to place the faucet retrograde 1 discharge assembly on the rotating assembly, used for the second of the O-ring 3 The upper assembly, the assembly assembly, the discharge assembly, the discharge box 4, the first sheet assembly, the second sheet assembly and the discharge assembly are uniformly distributed in the rotating assembly for the O-ring 3. Next, the pins 2 is disposed at the discharge end of the first she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com