Water permeable brick preparation molding processing technology

A technology for forming and processing permeable bricks, which is applied in the direction of manufacturing tools, ceramic molding machines, metal processing equipment, etc., can solve problems such as scratches, no equipment side wall trimming, burrs, etc., to improve work efficiency and avoid dust The effect of flying randomly and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

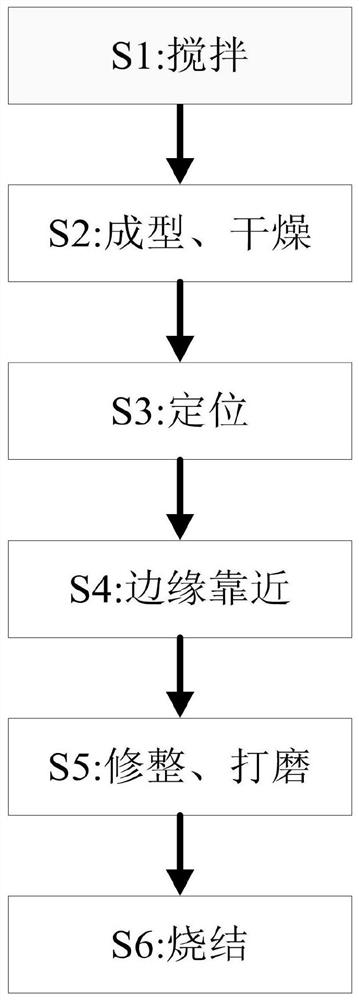

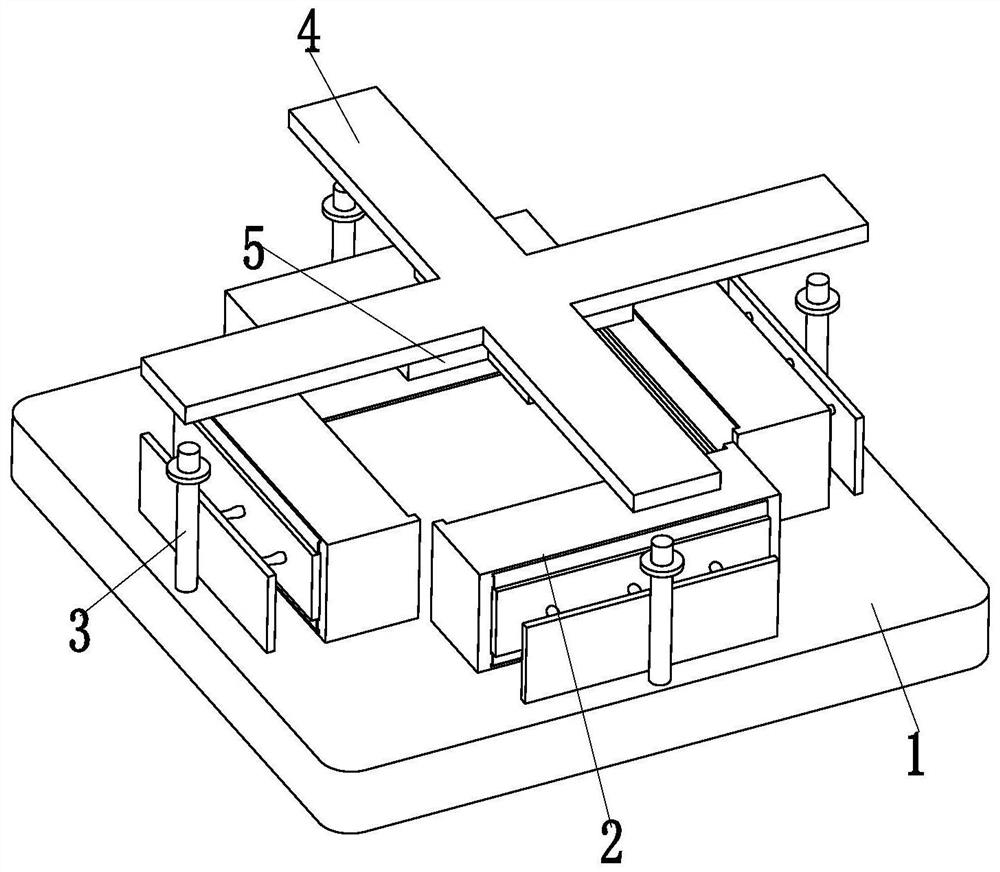

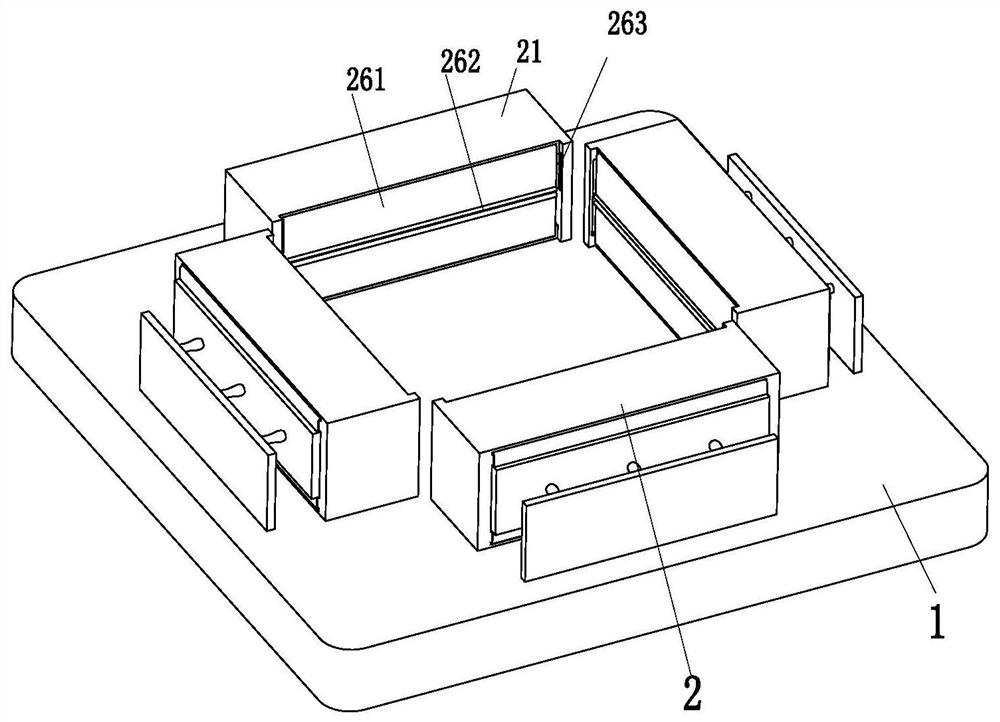

[0032] like Figure 1 to Figure 6 As shown, a permeable brick preparation and molding process uses a kind of edge trimming equipment, the edge trimming equipment includes a bottom plate 1, a trimming unit 2, an embedded column 3, an embedded plate 4 and a positioning rod 5, using the above edge trimming equipment The preparation and molding process of permeable bricks is as follows:

[0033] S1. Stirring: prepare different raw materials in proportion and stir them to form a mixed material;

[0034] S2. Forming and drying: input the mixed materials into the mold frame for pressing a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap