Glass fiber reinforced plastic pipeline fitting socket-and-spigot gluing method

A glass fiber reinforced plastic and bonding technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of troublesome insertion operation, insufficient joints, and disengagement, etc., and achieves convenient operation, bonding strength and The effect of high sealing performance and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Examples of the present invention are described in detail below; the examples described below by referring to the accompanying drawings are exemplary, are only for explaining the present invention, and should not be construed as limiting the invention.

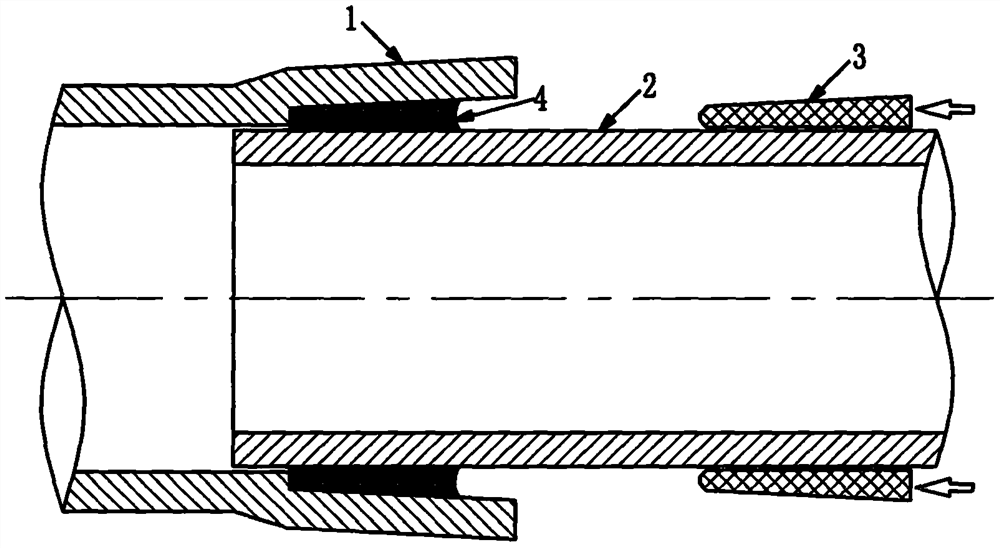

[0010] Please refer below figure 1 , the illustrated insert ring 3 is set on the intubation tube 2, and the intubation tube 2 is inserted in the socket tube 1. The diameter of the socket inner wall of the socket tube 1 is larger than the outer diameter of the intubation tube 2. After the position is fixed, an open annular socket groove is formed between the socket inner wall of the socket tube 1 and the outer wall of the intubation tube 2, the shape and size of the insertion ring 3 are basically the same as the above-mentioned annular socket groove, and the adhesive 4 is filled in the above-mentioned annular socket in the slot.

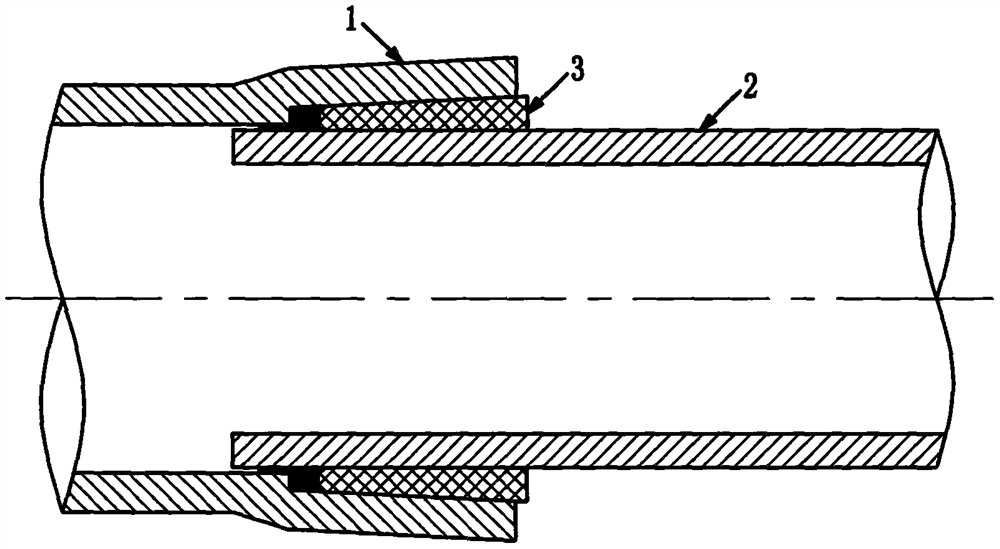

[0011] Please refer below figure 2 , a method for socket bonding of FRP pipe fittings as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com