Multi-position 3D scanning online detection method

A detection method, 3D technology, applied in measuring devices, image data processing, instruments, etc., can solve the problems of unguaranteed product quality, high dependence on operators, and low efficiency of manual detection, so as to improve efficiency and speed and the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

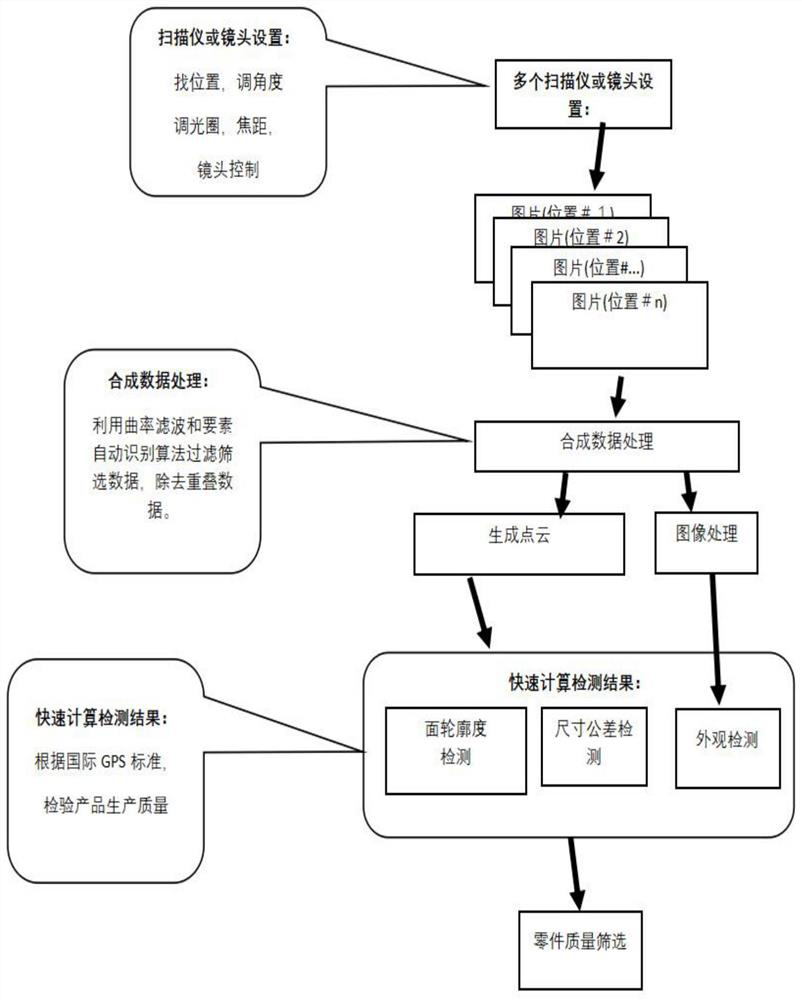

[0018] Such as figure 1 As shown, the multi-bit 3D scanning online detection method described in the present invention comprises the following steps:

[0019] Step 1: Install multiple sets of high-precision laser scanners or lenses on the production line to scan parts from different positions and angles;

[0020] Step 2: Install multiple sets of sensors with different positions and angles on the detection part, adjust the parameters of each group of sensors, and adjust the position, angle and quantity of the laser scanner or lens according to the actual position of the detection part;

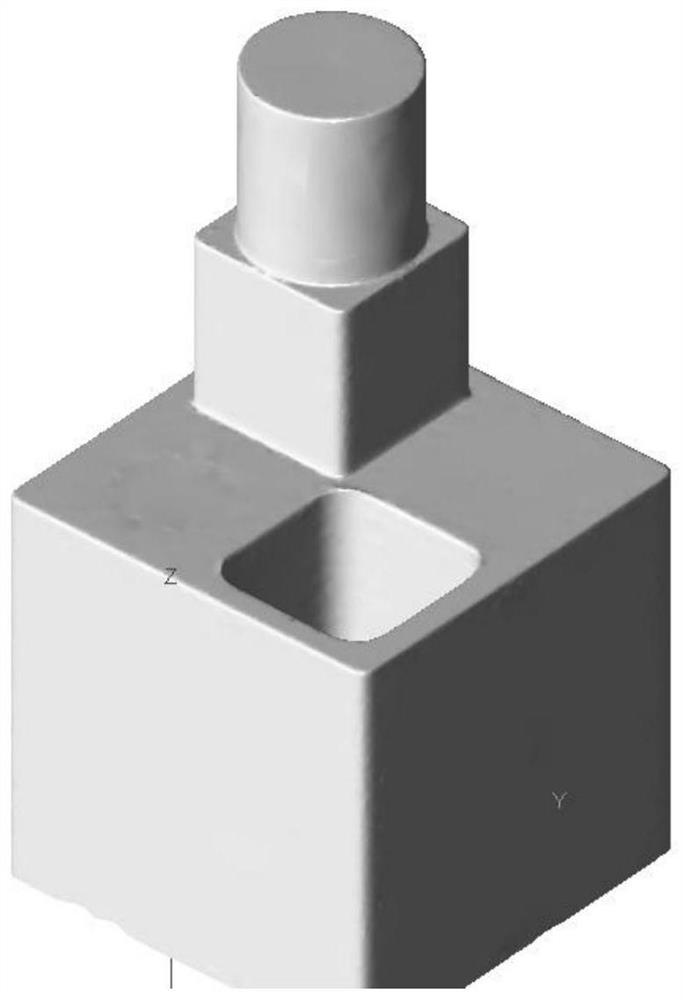

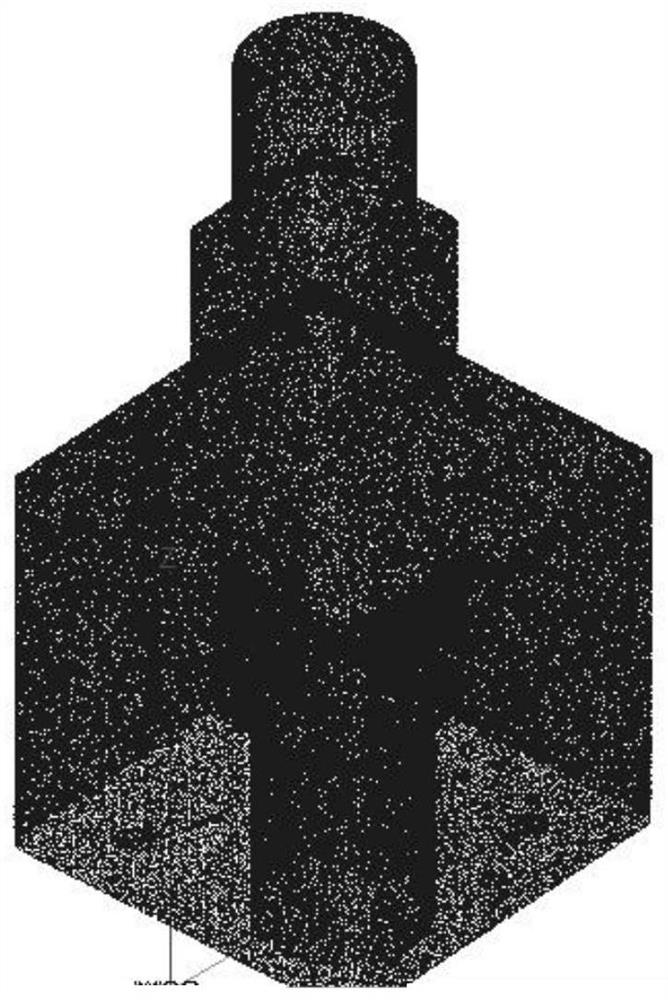

[0021] Step 3: Through multiple sets of high-precision scanners or lenses to collect the scanned data of the parts, the images of the data are overlapped and integrated to obtain a point cloud set containing the three-dimensional coordinates of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com