Acoustic emission sensor wall surface fixing device

A technology for acoustic emission sensors and fixing devices, which is applied to measuring devices, material analysis using acoustic emission technology, and instruments. Good stability and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

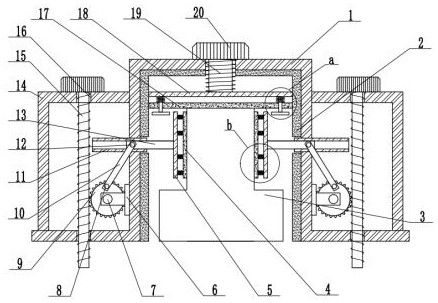

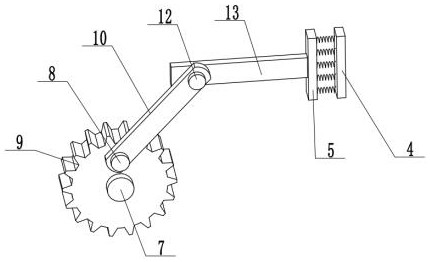

[0029] see Figure 1 to Figure 2 , a wall fixing device for an acoustic emission sensor, comprising an acoustic emission sensor body 3, a threaded rod 15, a stud 19, a limiting plate one 5 and a limiting plate two 18, the acoustic emission sensor body 3 is embedded in the mounting shell 1 Inside, the installation shell 1 plays a protective role and can prevent it from being damaged by impact

[0030] The limiting plate one 5 is slidably connected in the slide rail 11 embedded in the inner wall of the installation housing 1 through the slide bar 13, the limiting plate one 5 plays the role of limiting, and can prevent the acoustic emission sensor body 3 from being placed in the installation housing 1. Shaking from side to side, it has the characteristics of good stability. The end of the slide bar 13 is connected to the top of the connecting rod 10 through the pivot pin 12, and the bottom of the connecting rod 10 is connected to the gear 9 through the pivot pin 18. The connectin...

Embodiment 2

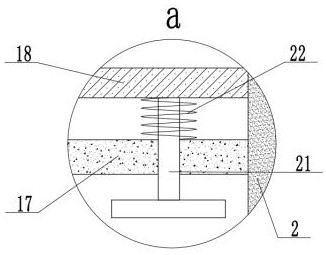

[0036] see Figure 1 to Figure 4 , a wall fixing device for an acoustic emission sensor, further comprising a limiting plate 2 18, the bottom of the limiting plate 18 is fixedly connected with a fixing pin 21, and the fixing pin 21 is embedded in a through hole provided on the surface of the buffer block 2 17 Inside, the side wall of the fixing pin 21 is sleeved with a damping spring 1 22, and the limiting plate 1 5 is connected to the buffer block 1 4 through the shock absorbing spring 2 23, and the buffer block 1 4 and the buffer block 2 17 can prevent acoustic emission The sensor body 3 is worn and plays a protective role. The shock absorbing spring 1 22 can weaken the longitudinal force of the AE sensor body 3 from the limit plate 18 in the process of violent shaking, and the shock absorbing spring 2 23 can weaken the force in the violent shaking process. During the process, the acoustic emission sensor body 3 is subjected to a lateral force from the limiting plate-5, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com