High-density low-loss optical fiber connector and connection method

A fiber optic connector and low-loss technology, applied in light guides, optics, instruments, etc., can solve the problems of insufficient firmness of the fixing device, loose fiber interface, high fiber loss, etc., achieve good elastic support effect, prevent loose connection, and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

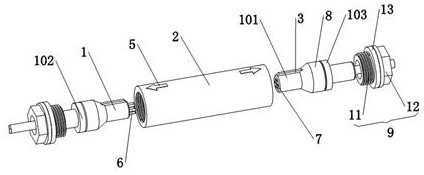

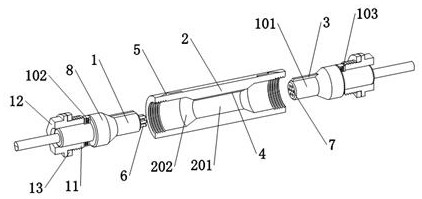

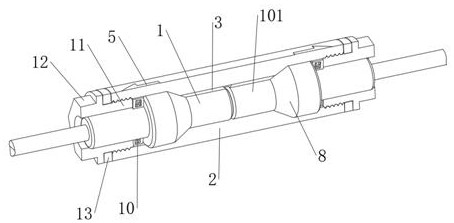

[0033] The present invention provides such Figure 1-6 A high-density and low-loss optical fiber connector is shown, including a first connector 1, a second connector 101 and a sleeve 2, one end of the first connector 1 is provided with a pin 6, and one end of the second connector 101 is provided with a pinhole 7, and the pin 6 is matched and inserted in the pin hole 7 for data connection and transmission, combined with figure 2 and image 3 As shown, the sleeve 2 is sleeved at the junction of the first joint 1 and the second joint 101, and the inside of the sleeve 2 is provided with a first positioning inner cavity 201, and the inner wall of the first positioning inner cavity 201 is aligned with the first joint 1 1. The outer wall of the second joint 101 is matched and in contact, so as to prevent offset between the first joint 1 and the second joint 101 .

[0034] to combine figure 1 , figure 2 and image 3 As shown, the outer walls of the first joint 1 and the second...

Embodiment 2

[0039] The inventors of the present case discovered during the implementation of the above-mentioned embodiment 1 that when using the connector, respectively insert the first joint 1 and the second joint 101 into the sleeve 2 according to the indication of the indicator arrow 5, and the guide rib 3 and the Insert the pin 6 into the pinhole 7 under the positioning of the guide groove 4, and then use the torque wrench to rotate the hexagonal stud ends 12 on both sides to squeeze the first elastic washer 102 and the second elastic washer 103, and the first elastic washer 102 squeezes Pressing the first joint 1 , the second elastic washer 103 presses the second joint 101 , further inserting the pin 6 into the pin hole 7 , and preventing the pin 6 from coming out of the pin hole 7 . In the above process, in order to ensure the normal conduction of the optical fibers on both sides and determine the optical signal transmission loss of each connecting part, after the pin 6 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com