Manufacturing method of double-end mica tape

A manufacturing method and technology of mica tape, applied in the direction of electrical components, insulators, circuits, etc., can solve the problems of collapse, low yield, cross disk and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of 20mm wide single-volume overlapping double-head phlogopite single-sided tape, its manufacturing method comprises the following steps:

[0027] (1) Blank tape production: (1-1) unwind the phlogopite paper and glass fiber cloth respectively through the automatic tension controller, (1-2) compound the glass fiber cloth with glue and mica paper, (1-3) mica After the paper is infiltrated, it enters the oven for drying, curing, and winding to obtain the mica tape blank;

[0028] (2) Blank tape slitting and splitting: cut the 1000mm wide mica tape base roll into 50 mica tape reels with a width of 20mm;

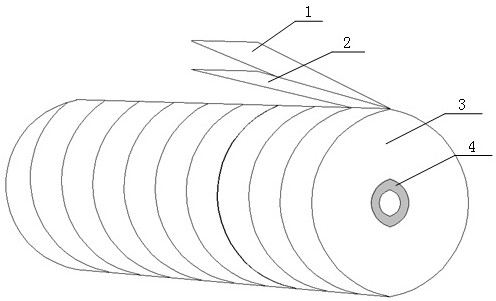

[0029] (3) Winding: Install two 20mm-wide mica tape reels on the two unwinding ends. After passing through the automatic constant tension system and positioning with multiple positioning wheels, the two mica tape heads are neatly overlapped. The rewinding arm at the end of the reel moves to reel into a mica tape;

[0030] (4) Use silicone pressure-sens...

Embodiment 2

[0033] Embodiment 2 A 4mm wide single disc side-by-side double-headed phlogopite three-in-one belt, its manufacturing method comprises the following steps:

[0034] (1) Blank tape production: (1-1) unwind the phlogopite paper and glass fiber cloth respectively through the automatic tension controller, (1-2) compound the glass fiber cloth with glue and mica paper, (1-3) mica After the paper is infiltrated, it enters the oven to dry and solidify, and then it is rewound after compounding with the film to obtain the mica tape blank;

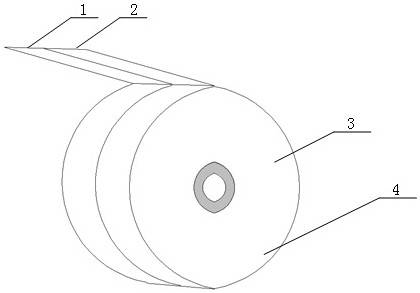

[0035] (2) Blank tape slitting: After the 1,000mm wide kilometer mica tape blank master roll is opened four times, after passing through the automatic deviation correction constant tension system again, it is cut into mica tape strips by a precision slitting machine, and passed through the collection The winding device is wound on a set of coil cores with a width of 8mm to obtain a 4mm wide single-disk side-by-side double-headed phlogopite three-in-o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com