A transformer coil winding device

A transformer coil and winding device technology, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of wasting manpower, transformer scrapping, and transformer performance degradation, so as to achieve good practicability and prevent loose parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

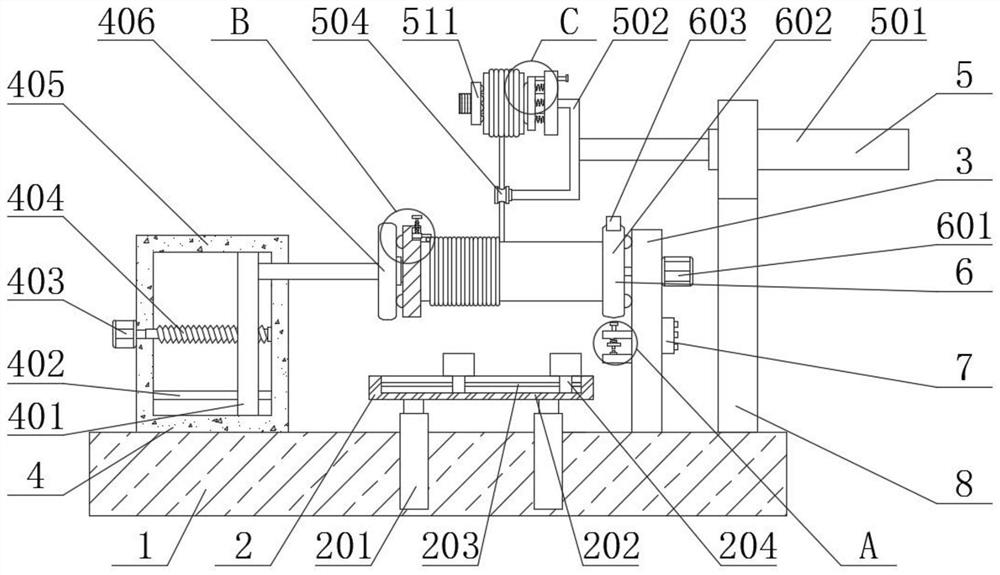

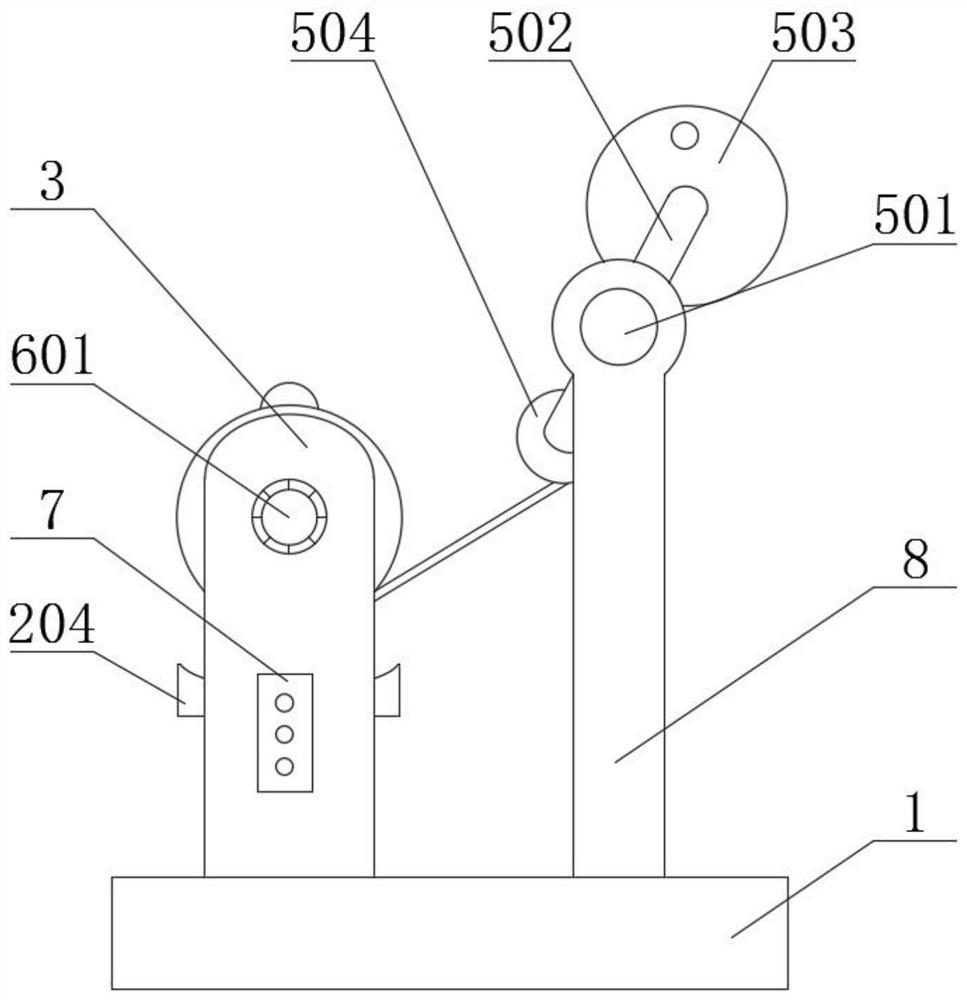

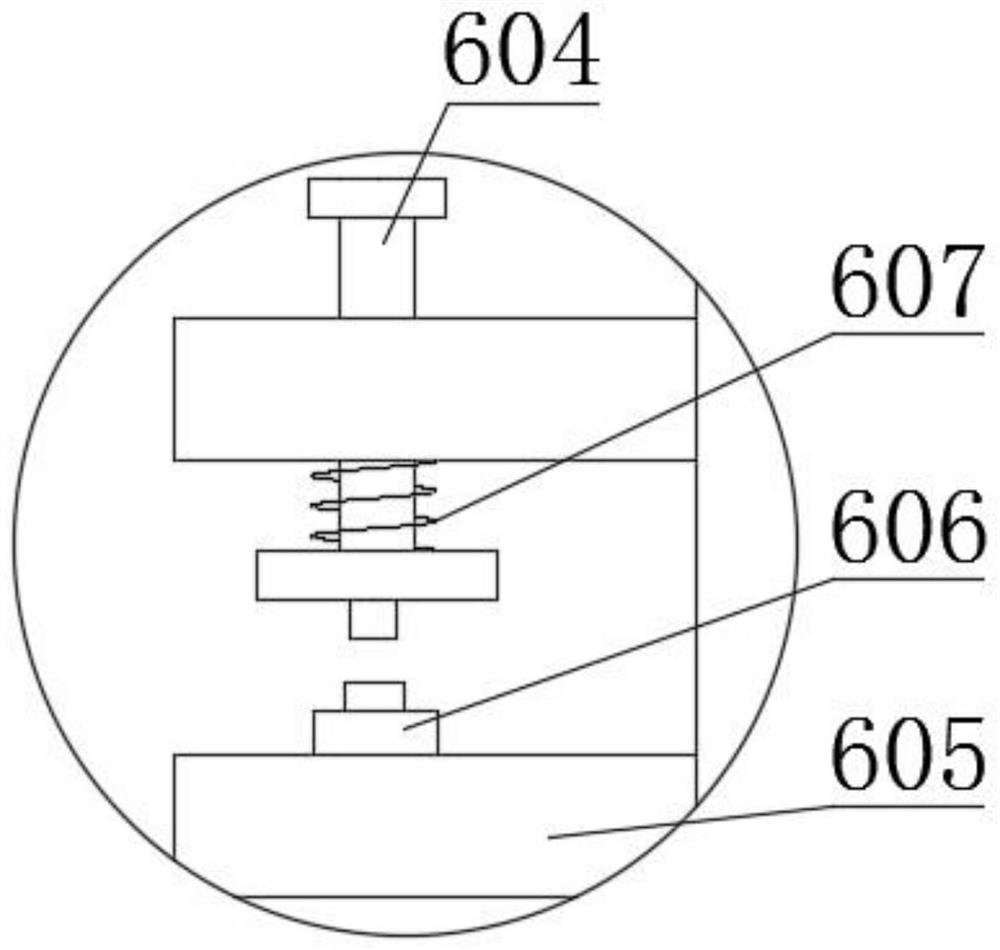

[0029] see Figure 1-7 , the present invention provides a kind of technical scheme:

[0030] A transformer coil winding device, comprising a base 1, a side plate 3 fixedly connected to the top of the base 1, and a support ring 8 fixedly connected to the top of the base 1, characterized in that the support ring 8 is arranged on the right rear side of the side plate 3, The right end of the plate 3 is fixedly connected with the controller 7, and the side plate 3 is provided with a rotating circle marking mechanism 6, which can realize accurate counting of the number of turns, and the rotating circle marking mechanism 6 includes a fixed plate 605 and a second motor. 601, the inner side of the fixed plate 605 on the upper side is slidably connected with a push rod 604, the outer side of the push rod 604 is provided with a second spring 607, and the two ends of the second spring 607 are respectively connected with the bottom end and the bottom end of the fixed plate 605 on the upper...

Embodiment 2

[0034] Workflow: In Example 2, the same parts as in Example 1 will not be repeated, the difference is that when feeding, the lifting screw 901 is rotated, and the lifting screw 901 can move upward. When the lifting screw 901 moves upward, The lifting screw 901 will drive the telescopic plate 902 to move upward, one end of the coil 506 will be sent away, the first electric telescopic rod 201 will be stretched, the support plate 204 will be close to the lower side of the iron rod, and the first motor 403 will drive the first screw 404 to rotate, The first screw 404 drives the outer slide plate 401 to move to the left, wherein the set second limit rod 402 plays a limiting role, which can increase the stability of the slide plate 401 when it moves. When the slide plate 401 moves to the left, The sliding plate 401 drives the top plate 406 to move to the left, and the top plate 406 drives the left splint 407 to move to the left. At this time, the iron rod will move downward under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com