Pattern-marking method for special and obese structure of Shumeier women's prototype clothing

A technology for clothing and women's clothing, applied in the field of Shumeier prototype women's clothing special body and fat structure plate making, to achieve the effect of increasing customer satisfaction, reducing the repair rate, and solving the problem of repeated modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

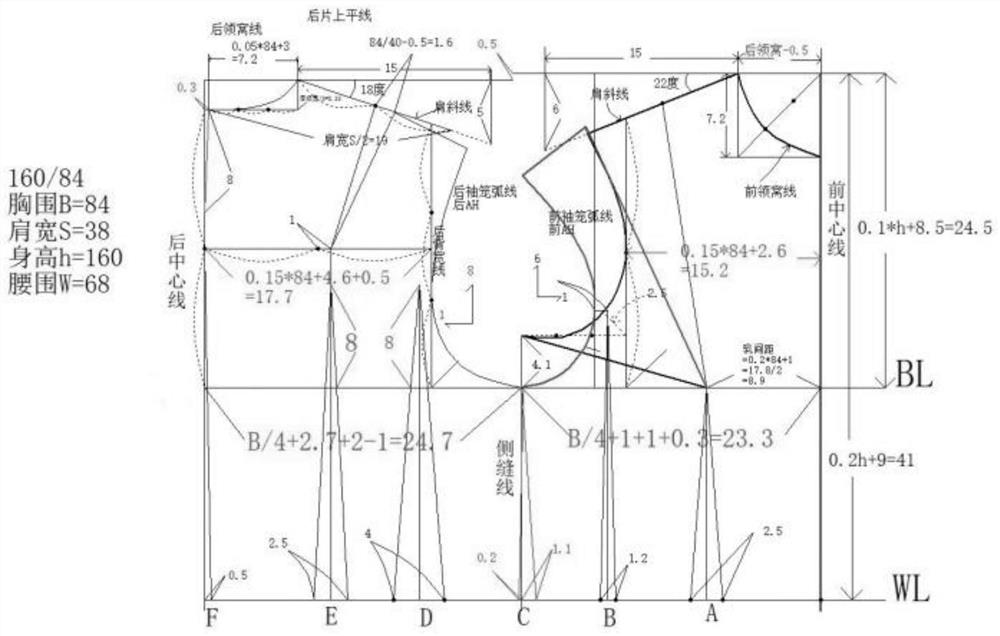

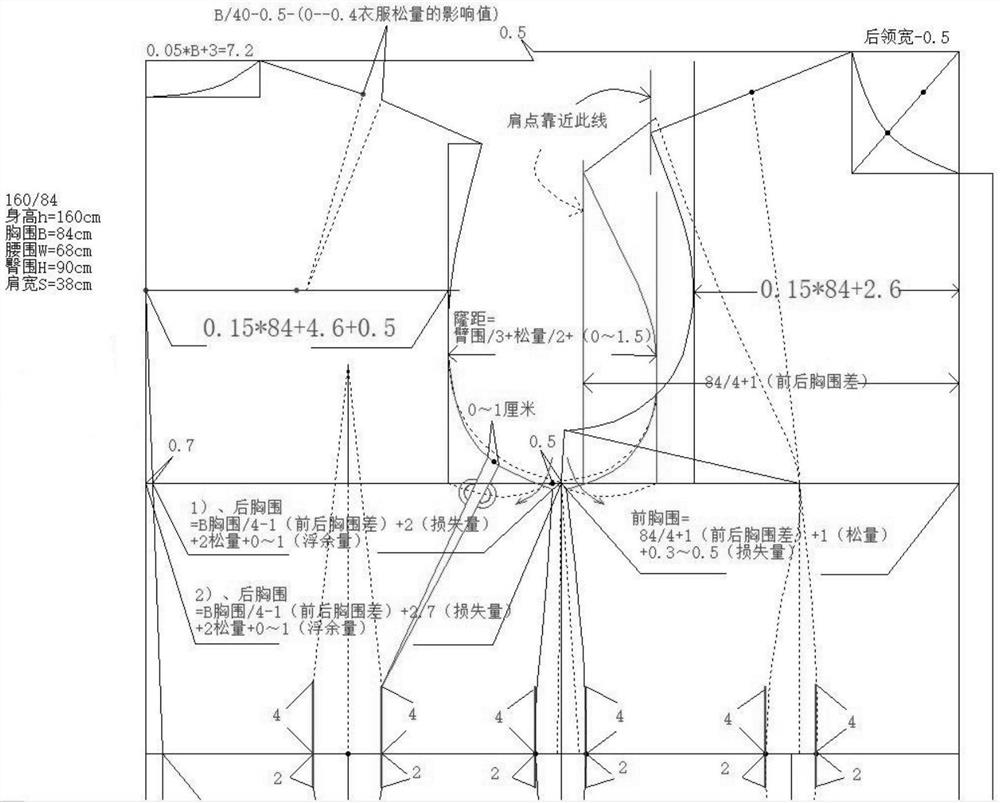

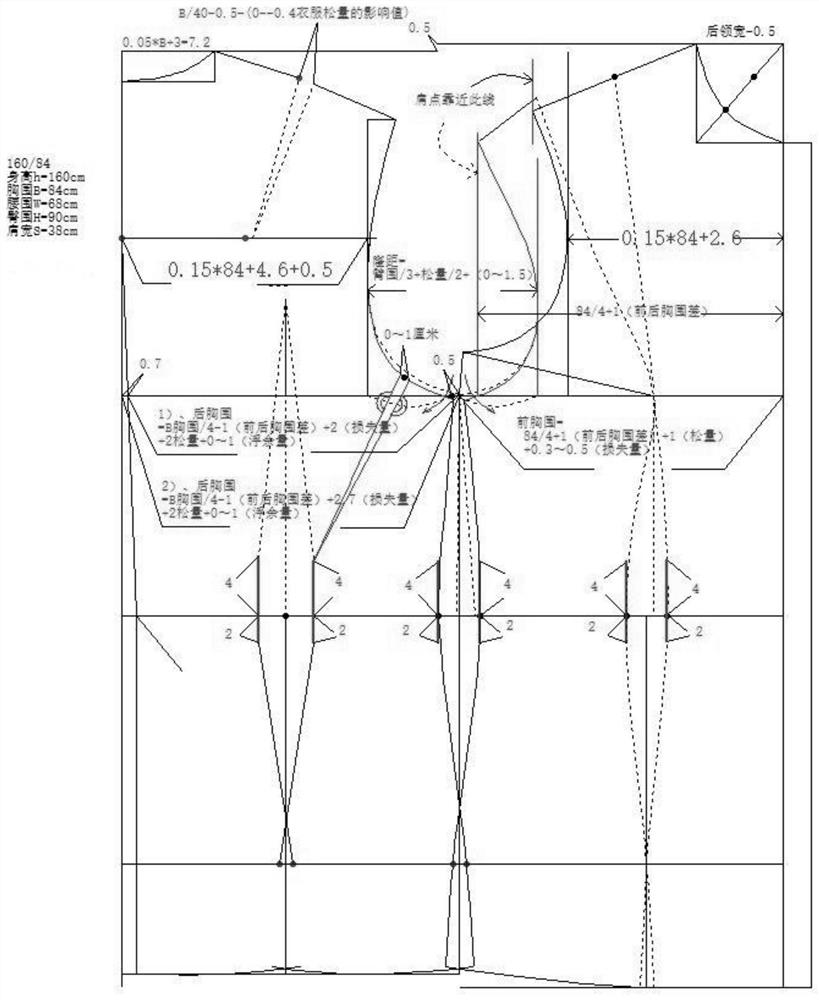

[0105] Embodiment: one), formula design: 160 height / 84 bust

[0106] 1. The formula design of the back bust:

[0107] A), bust (clean body) / 4-1 (difference between front and rear bust) + 2 (loss) + 2 looseness + 0 ~ 1 (float)

[0108] B), bust (clean body) / 4-1 (difference between front and rear bust) + 2.7 (loss) + 2 loose + 0 ~ 1 (floating)

[0109] The reason for the two formulas of the back bust is that the measurement parts are different. The first formula is measured from the back seam to the side seam; the second formula is measured from the back center line to the side seam;

[0110] 2. Front bust formula design:

[0111] Bust (clean body) / 4+1(difference between front and rear bust)+1(looseness)+0.3~0.5(loss)

[0112] 3. Back width formula design:

[0113] 160 / 84=0.15*bust (clean body)+4.6cm+0.5cm

[0114] 160 / 88=0.15*bust (clean body)+4.6cm+0.5cm

[0115] 160 / 92=0.15*bust (clean body)+4.8cm+0.5cm

[0116] 160 / 96=0.15*bust (clean body)+4.8cm+0.5cm

[0117] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com