Machining method of eccentric groove of casing

A processing method and eccentric groove technology, which are applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of eccentric clamping alignment errors, hidden quality problems, and difficulty in distinguishing, so as to save costs and eliminate quality. Hidden danger, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

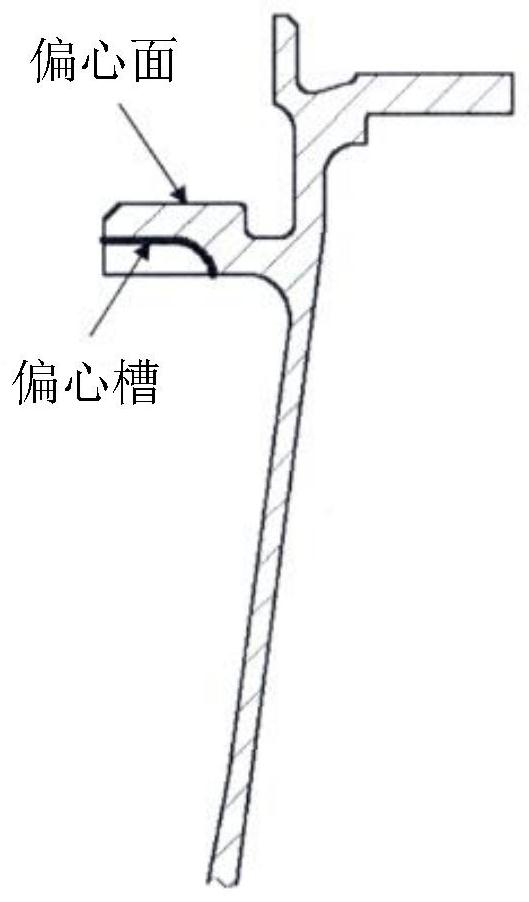

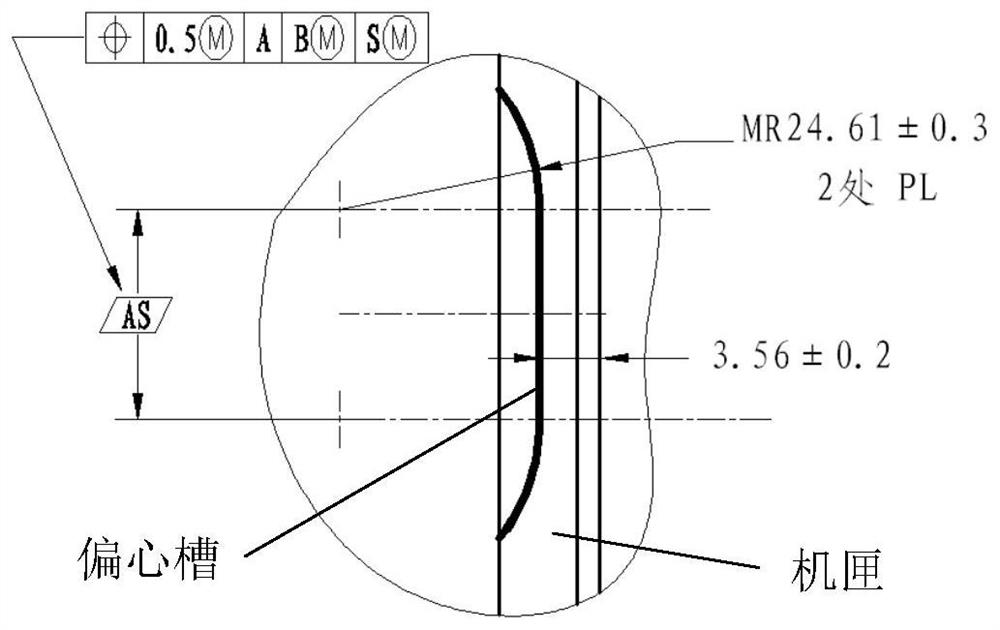

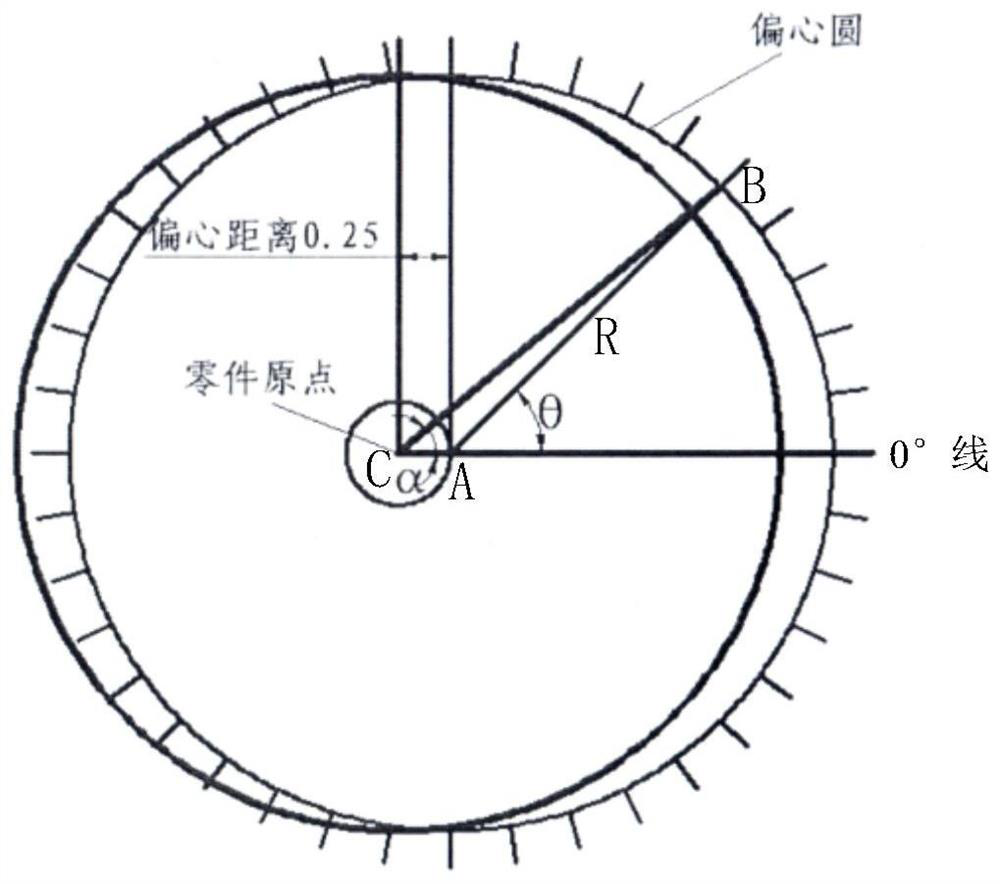

[0029] like figure 1 and figure 2 As shown, taking an eccentric turbine casing as an example, the eccentric distance d between the origin of the eccentric circle of the casing and the origin of the part is 0.25mm, and there are 40 eccentric grooves on the eccentric surface to be processed, and the 40 eccentric grooves are centered on the origin of the eccentric circle. , evenly arranged on a circle with radius R=500mm.

[0030] like image 3 and Figure 4 Shown, a kind of machining method of casing eccentric groove, comprises the following steps:

[0031] S1. Under the coordinates of the origin of the part, the coordinates of the origin of the ecce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius r | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com