Anti-toppling and anti-leakage vehicle-mounted garbage can for new energy vehicle

A new energy vehicle, anti-dumping technology, applied in special positions of vehicles, vehicle parts, transportation and packaging, etc., can solve the problem of easy dumping of vehicle-mounted trash cans, and achieve the effect of enhancing anti-dumping ability and ensuring normal driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

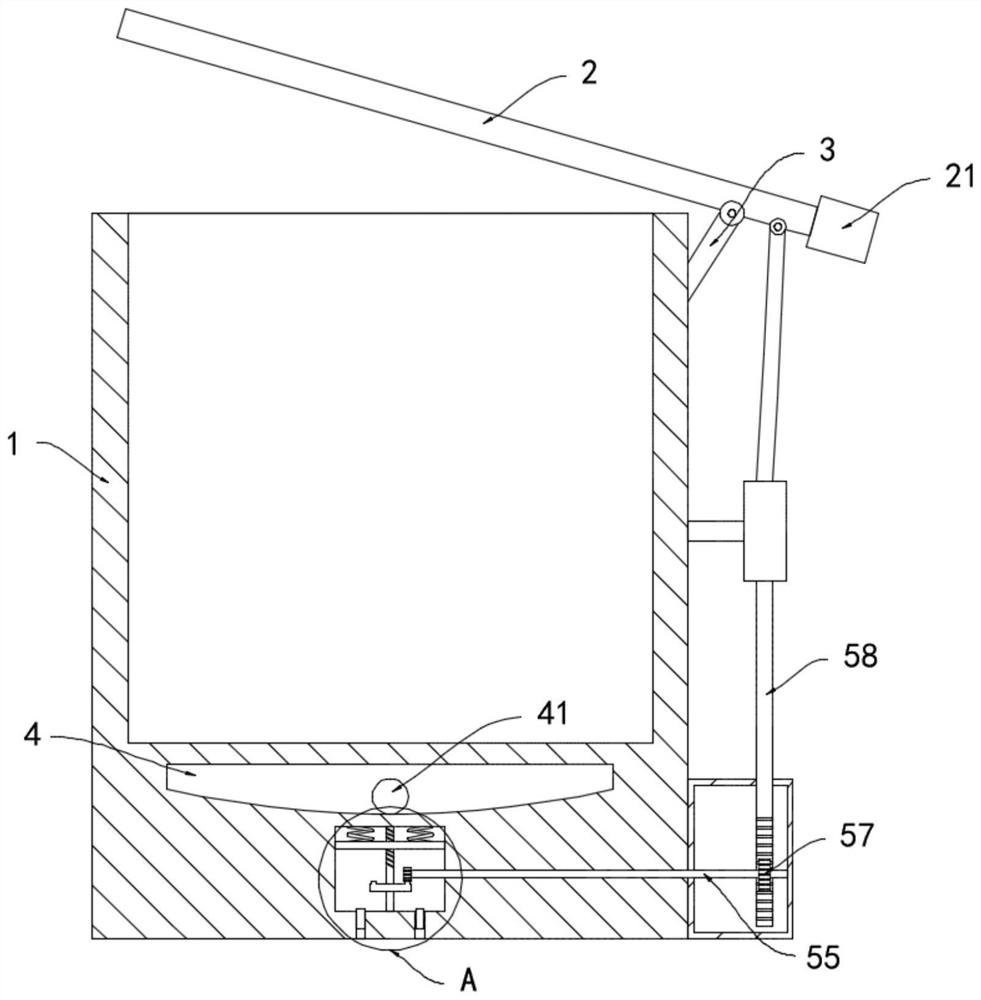

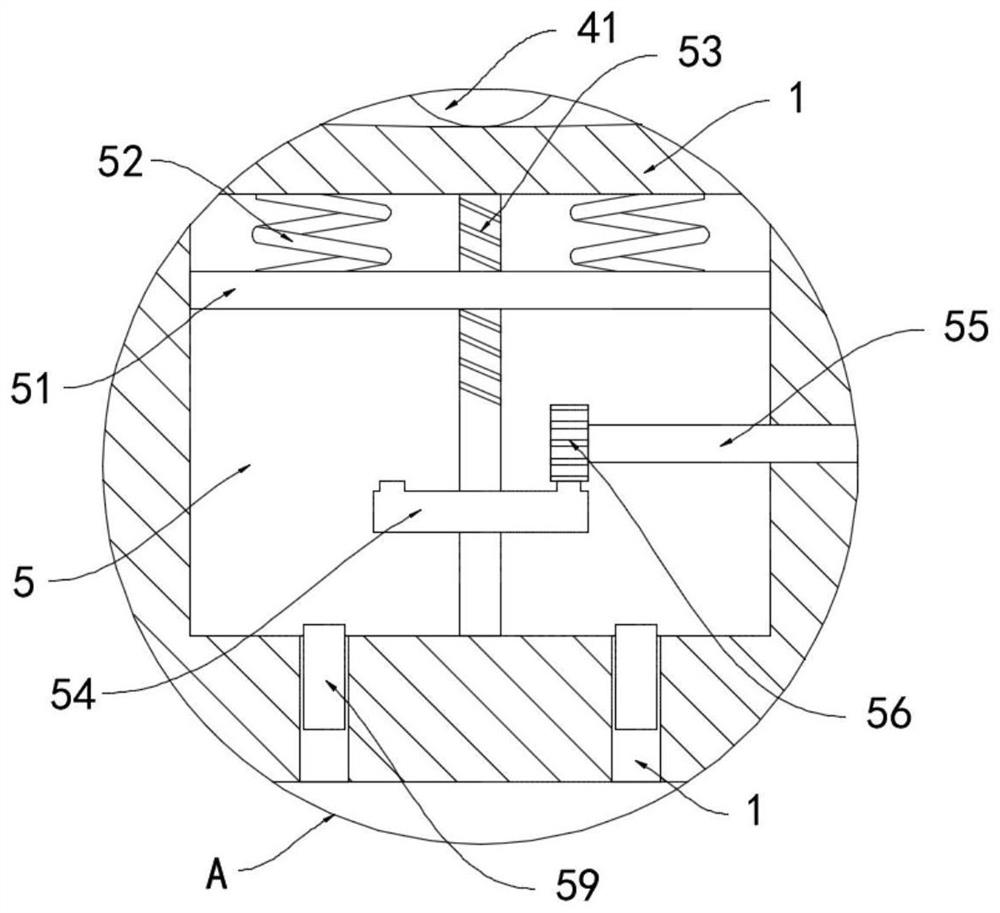

[0024] Such as Figure 1-2 As shown, a vehicle-mounted garbage can for new energy vehicles that prevents dumping and leakage includes a cylinder body 1 and a cover body 2. A support rod 3 is fixedly connected to the side wall of the upper end of the cylinder body 1, and the upper end of the cover body 2 and the support rod 3 Rotational connection, the end of the cover body 2 closer to the support rod 3 is fixedly connected with a counterweight 21, and the counterweight 21 makes the weight of the two ends of the cover body 2 farther from the support rod 3 and closer to the same, similar to the structure of a seesaw , the cover body 2 rotates around the support rod, the bottom of the cylinder body 1 is provided with a sliding chamber 4, the lower part of the sliding chamber 4 is provided with a transmission chamber 5, and the bottom surface of the sliding chamber 4 is arranged in a downwardly concave arc shape. 4 is provided with the magnetic ball 41 that can roll freely.

[00...

Embodiment 2

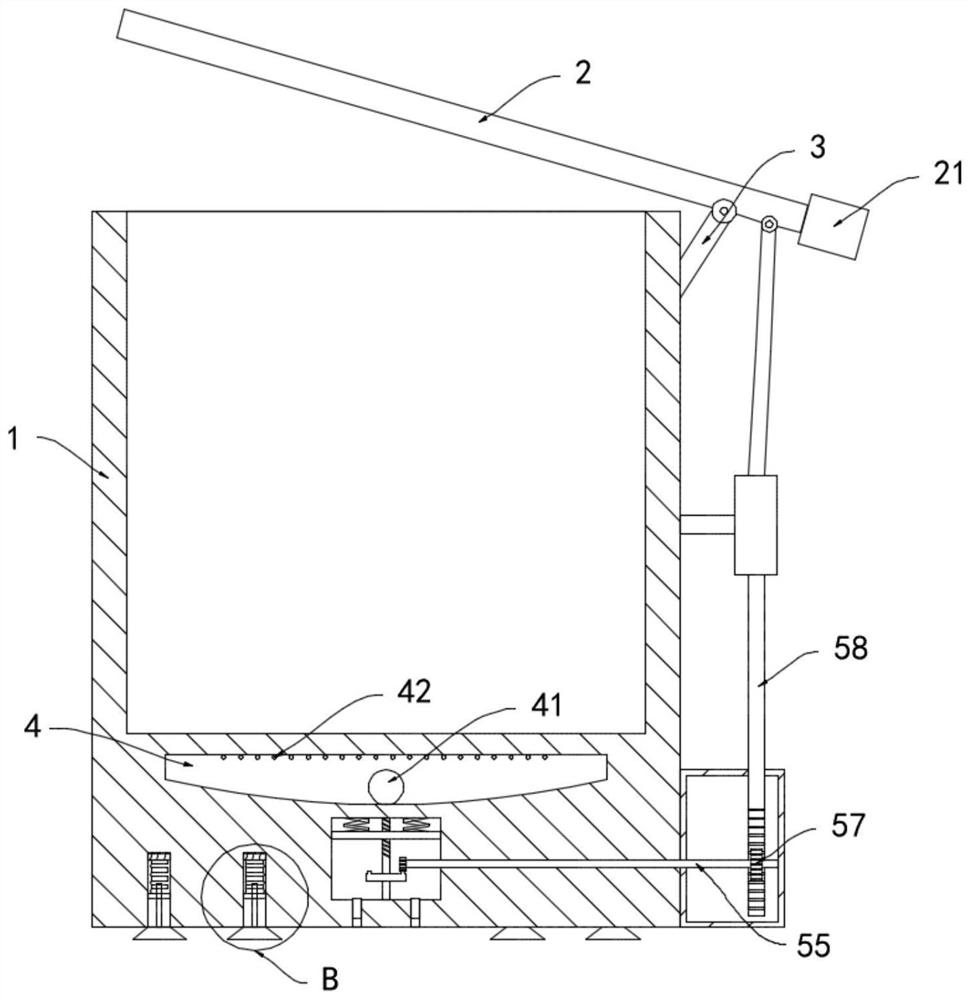

[0032] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that: the top surface of the sliding cavity 4 is fixed with an induction coil 42, and the bottom surface of the cylinder 1 is provided with a plurality of grooves 6, and the plurality of grooves 6 are evenly distributed in the cylinder. At the bottom of the body 1, a sucker 61 is fixedly connected to the opening of the groove 6, an electromagnet 62 is fixedly connected to the top surface of the groove 6, and a helical coil 63 is wound around the electromagnet 62, and the helical coil 63 is electrically connected to the induction coil 42 The lower end of the electromagnet 62 is fixedly connected with a magnet block 65 through an elastic bellows 64, and the magnet block 65 is slidingly connected with the side wall of the groove 6, and the elastic bellows 64 communicates with the inside of the suction cup 61 through an air duct 66.

[0033] In this embodiment, when the vehicle is accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com