Negative plate and laminated lithium ion battery comprising same

A negative electrode sheet and negative electrode technology, applied in the field of laminated lithium-ion batteries, can solve the problems of incompatibility with high energy density and fast charging, achieve both fast charging and high energy density, widen the lithium analysis window, and quickly The effect of increasing the charging level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Add 0.5wt% conductive carbon black, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.9wt% graphite a, and then adjust it into negative electrode slurry A with water. Add 0.5wt% conductive carbon black, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.9wt% graphite b, and then adjust it into negative electrode slurry B with water.

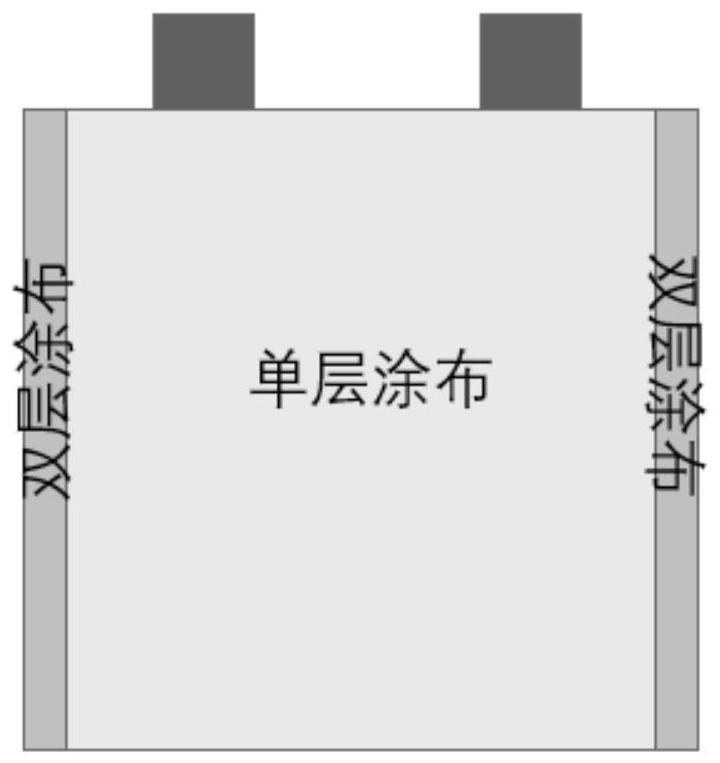

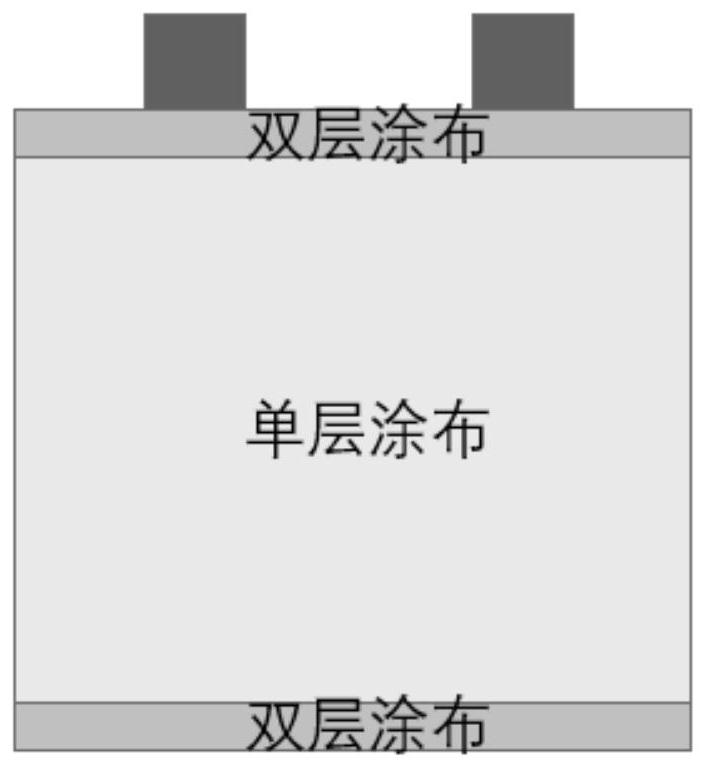

[0066] Such as Figure 4 As shown, the negative electrode sheet includes a negative electrode collector, and a central area, a first edge, a second edge, a third edge, and a fourth edge are provided on the first surface of the negative electrode collector; the first edge, The second edge, the third edge and the fourth edge are arranged around the central area, and the first edge and the third edge are arranged opposite; the second edge and the fourth edge are arranged opposite;

[0067] Wherein, a first coating area is set in the central area, and a second coating area is set in the first...

Embodiment 2

[0073] Others are the same as in Example 1, only the area of double-layer coating is different, that is, the area of the first coating area is 1 / 2 of the sum of the areas of the first coating area and the second coating area, such as Figure 4 As shown, the areas of the first edge, the second edge, the third edge and the fourth edge are all 1 / 8.

Embodiment 3

[0075] Others are the same as in Example 1, except that the compositions of slurry A and slurry B are different.

[0076] Add 0.5wt% conductive carbon black, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.9wt% graphite a, and then adjust with water to prepare negative electrode slurry A. Add 1.0wt% conductive carbon black, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.4wt% graphite b, and then adjust with water to prepare negative electrode slurry B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com