Novel liquid cooling plate

A liquid cold plate, a new type of technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problem of poor heat transfer uniformity of the liquid cold plate, and achieve the effect of reducing temperature difference, benefiting uniformity, and achieving uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

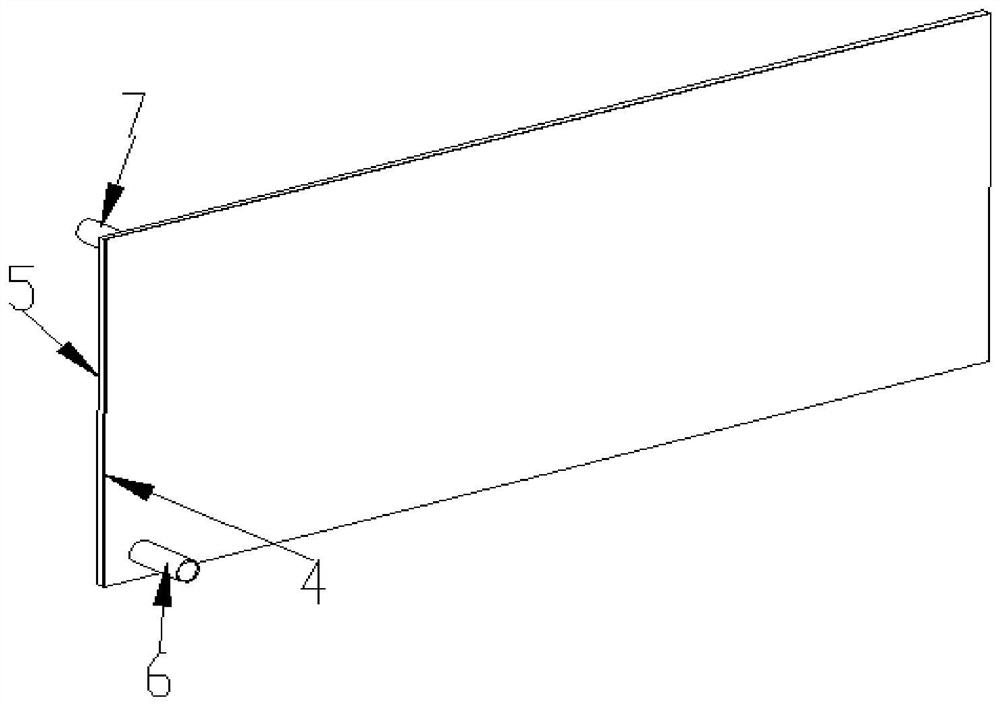

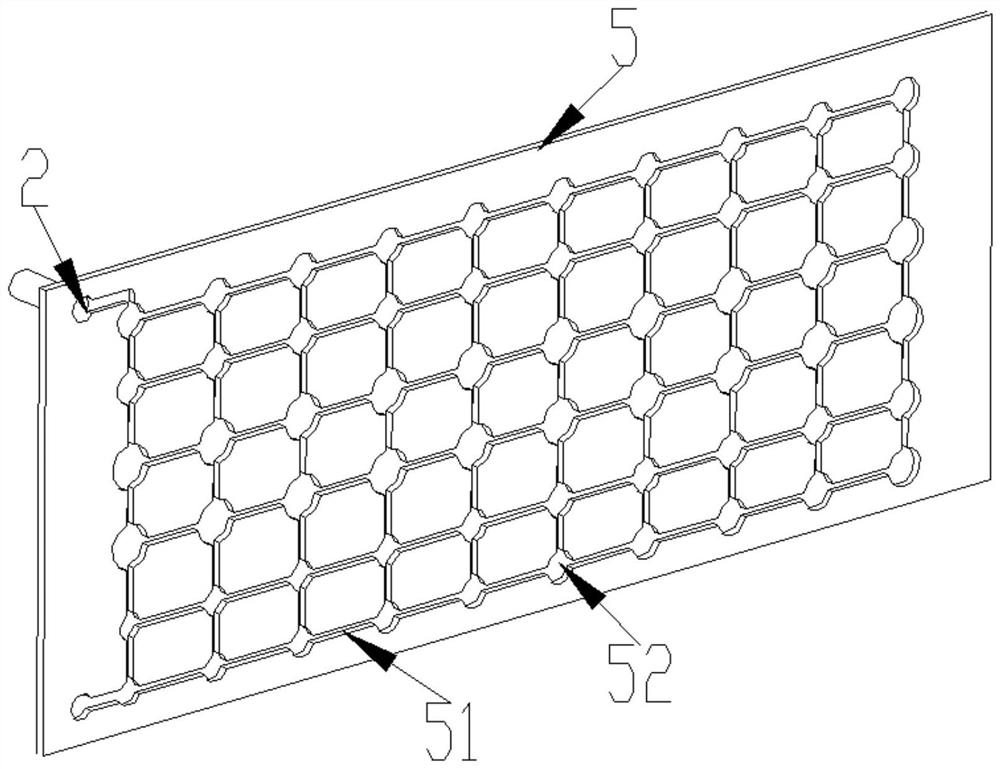

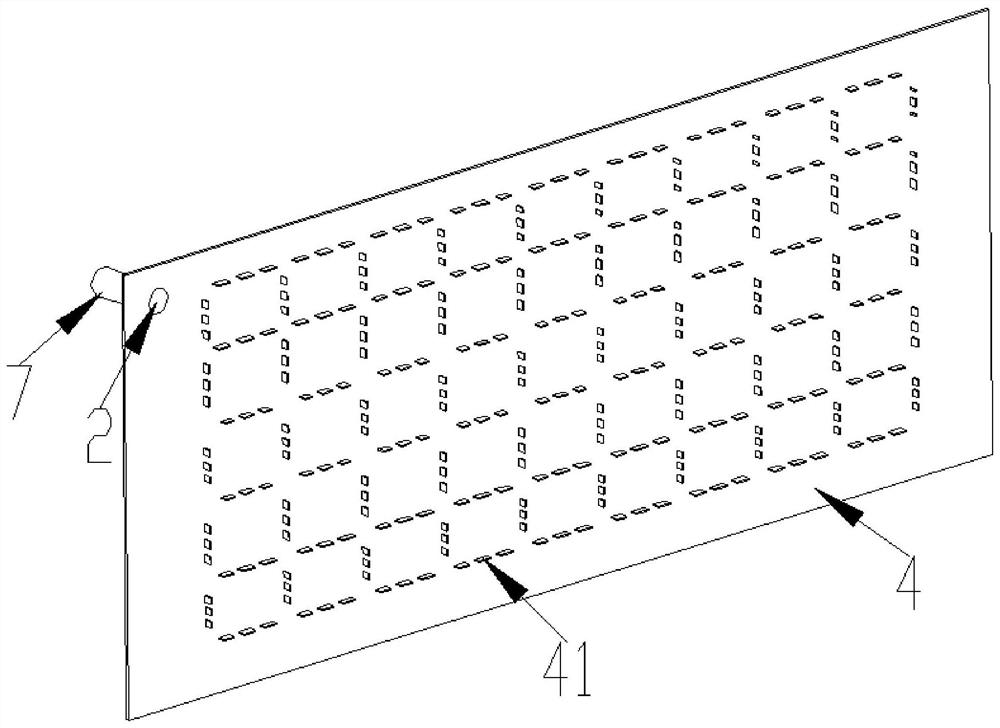

[0042] A new type of liquid cold plate, the new type of liquid cold plate includes a front cover 4 and a rear cover 5, the front cover 4 and the rear cover 5 are arranged oppositely and the two are attached, and the rear cover 5 is provided with a grid concave Groove 51, grid groove 51 is the rectangular grid structure of horizontal and vertical intersection, and grid groove 51 is used for forming the internal flow path between front cover plate 4 and rear cover plate 5, and the intersection of grid groove 51 A circular groove 52 is formed on the point, and the circular groove 52 is used to form a liquid tank structure 3 that increases the heat exchange area. The front cover 4 is provided with a spoiler protrusion structure 41, and each spoiler protrusion structure 41 is just right Arranged in the middle of the corresponding horizontal flow channel and vertical flow channel, it can enhance the turbulence and improve the heat exchange effect;

[0043] Along the height direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com