Thin plating type cold-rolled tinned steel plate and manufacturing method thereof

A tin-coated steel sheet and a manufacturing method technology are applied in the fields of cold-rolled tin-coated steel sheet and its manufacture, thin-coated cold-rolled tin-coated steel sheet and its manufacture, which can solve the problems affecting the compactness of the coating layer and the roughness of the tin layer, and achieve the realization method. Simple, reduce dew point, solve the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

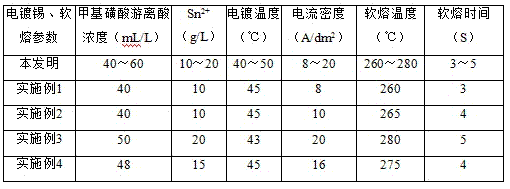

[0042] The present invention will be further described below in conjunction with Examples 1-4.

[0043] Table 1 shows the chemical composition (by weight percentage) of the cold-rolled hard steel plate of the embodiment of the present invention, the balance being Fe and unavoidable impurities.

[0044] Table 1 The chemical composition of the cold-rolled hard steel plate of the embodiment of the present invention, unit: weight percent

[0045]

[0046] For the above thickness of 0.17 ~ 0.35mm, lower yield strength R PL Annealing and smoothing the cold-rolled hard steel plate of 750-850MPa in a vertical continuous annealing furnace; the annealing process is: the annealing (soaking section) temperature of the steel plate in the vertical continuous Section) time: 60s~120s; leveling process: use double-stand four-roller wet leveling, work rolls use chrome-plated rolls, 1-stand work rolls use EDM texturing rolls with a roughness of Ra1.2~1.6um, The rolling force is 500-600t; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com