Preparation method of large titanium alloy cast ingot containing trace elements

A trace element, titanium alloy technology, applied in the field of titanium alloy melting, can solve the problems of small electrode block splicing, multiple remelting, etc., to achieve the effect of being beneficial to uniformity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method specifically comprises the following steps:

[0025] Step 1. Using sponge titanium and master alloy as raw materials, carry out weighing and batching according to the nominal composition of the titanium alloy to be prepared and the number of blocks, to obtain N parts of mixed raw materials, and prepare N parts of trace element powder.

[0026] Step 2. Pour half of each mixed raw material into its corresponding block, pour each portion of trace element powder into its corresponding block, and then pour the remaining half of each mixed raw material into its corresponding In the block; so that the trace element powder is placed in the middle part of the mixed raw material.

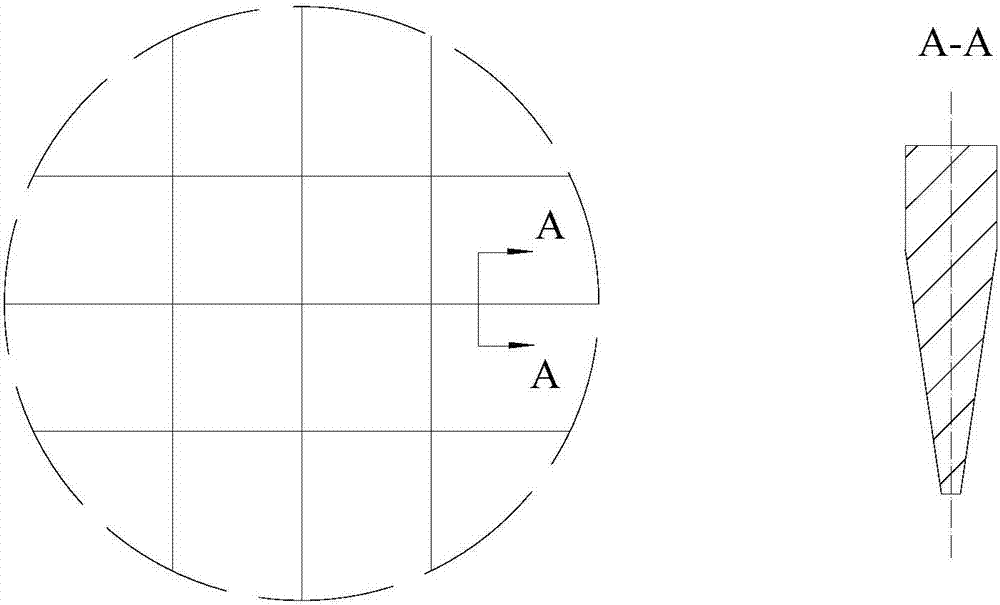

[0027] Such as figure 1 As shown, the horizontal and vertical grid-shaped auxiliary brackets divide the mold cavity into sixteen parts, and sixteen parts need to be weighed and mixed to obtain sixteen parts of ingredients, and each part of mixed raw materials is poured into its ...

Embodiment 1

[0032] Embodiment 1 Φ620-2880Kg ingot smelting method of TA9 (Ti-0.2Pd) alloy: the raw materials are 0-grade sponge titanium and industrial pure Pd powder, and the alloy proportion is according to the nominal composition Ti-0.2Pd (wt%). In the mold cavity of Φ460, a grid-shaped auxiliary support is placed in advance to divide the cavity into sixteen points. Batch and weigh 16 times according to the weight of 10Kg respectively, and pour into 16 grid files. Especially in each grid, the titanium sponge is poured in twice, and the Pd powder is placed in the middle. After loosening and taking out the bracket, press it into a Φ460-160Kg TA9 titanium alloy electrode block at one time. The thickness of the pressed large single-weight electrode block is about 300mm. A total of 18 electrode blocks were prepared and welded into 2 consumable electrodes. Subsequent vacuum self-consumption smelting twice to obtain Φ620-2880Kg ingots. The detection results of the Pd element content in th...

Embodiment 2

[0033] Embodiment 2 TC23 (Ti-6Al-4V-0.1Ru) titanium alloy Φ620-3000Kg ingot smelting method: the raw materials are selected 0 grade sponge titanium, AlV55 master alloy, industrial pure aluminum beans, industrial pure Ru powder, and the alloy ratio is according to Ti- 6.2%Al-4.2%V-0.1Ru (wt%). In the mold cavity of Φ380, a grid-shaped auxiliary support is placed in advance to divide the cavity into sixteen points. Respectively by the weight of 6.25Kg batching, weighing sixteen times, pour into sixteen grid files. Especially in each grid, the mixed sponge titanium and alloy materials are poured in twice, and the Pd powder is placed in the middle. After loosening and taking out the bracket, press it into a Φ380-100Kg TC23 titanium alloy electrode block at one time. The thickness of the pressed large single-weight electrode block is about 300mm. A total of 30 electrode blocks were prepared and welded into 4 consumable electrodes. Subsequent vacuum self-consumption smelting thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com