Low-temperature plasma waste gas treatment system

A low-temperature plasma and waste gas treatment technology, used in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of easy corrosion of equipment, high operating costs, no degradation effect, etc., to achieve uniformity and increase sweeping area. , Improve the effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

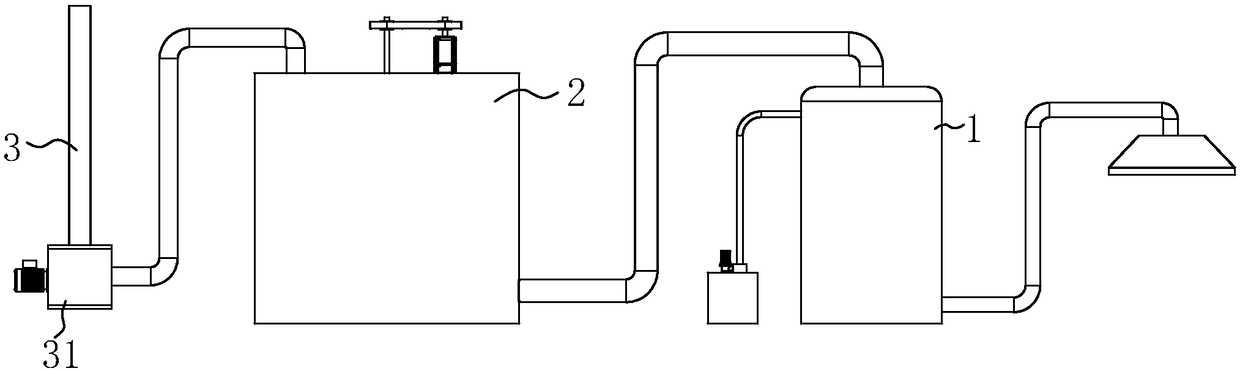

[0039] as attached figure 1As shown, a low-temperature plasma waste gas treatment system includes a spray tower 1 , a plasma purification device 2 and a chimney 3 . Here, the position near the bottom of the spray tower 1 communicates with an exhaust gas absorption hood, and the top of the spray tower 1 communicates with the side near the bottom of the plasma purification device 2, and the top of the plasma purification device 2 communicates with the chimney 3 The exhaust fan 31 is connected.

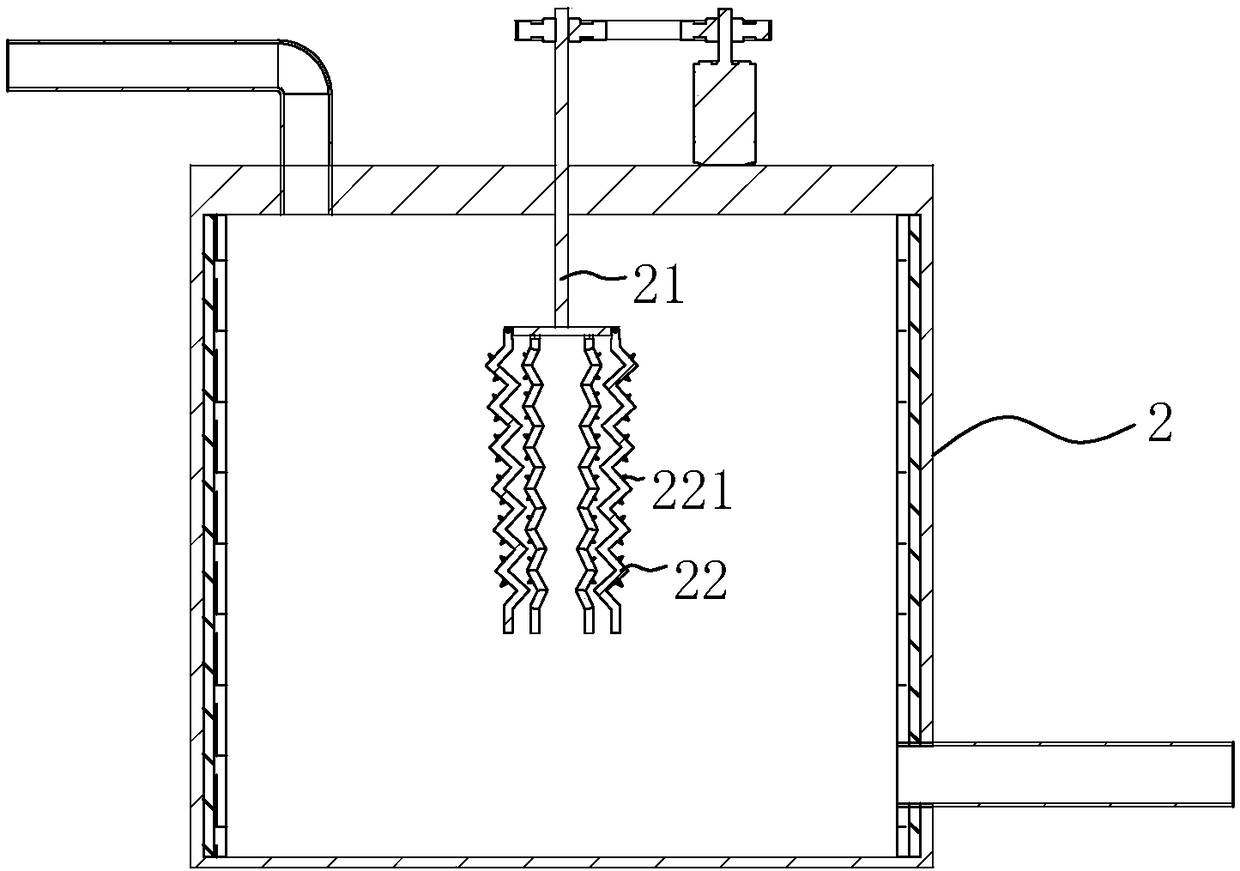

[0040] Among them, as attached figure 2 As shown, a rotating shaft 21 is pierced at the center of the top of the plasma purification device 2 , and the upper end of the rotating shaft 21 is connected to a motor outside the plasma purification device 2 . The rotating shaft 21 can be driven by the motor to rotate. At the same time, the lower end of the rotating shaft 21 is hinged with a number of probes 22 along the radial direction of the rotating shaft 21, and the probes 22 can be fl...

Embodiment 2

[0046] as attached Figure 4 As shown, a low-temperature plasma exhaust gas treatment system is based on the first embodiment, and the top of the plasma purification device 2 also has a number of spray holes 23, and the spray holes 23 communicate with the external liquid storage tank 24. The solution in the liquid storage tank 24 is an alkaline hydrogen peroxide solution, which is conducive to improving the preservation of hydrogen peroxide and reducing the decomposition rate of hydrogen peroxide. When the alkaline hydrogen peroxide solution is sprayed down, the probe 22 will splash the alkaline hydrogen peroxide solution in the process of rotation, which can speed up the purification of the exhaust gas.

[0047] In addition, when the exhaust gas enters the plasma purification device 2, the exhaust gas will be oxidized and decomposed to produce carbon dioxide and water, which will be absorbed by the alkaline hydrogen peroxide, so that the pH value of the alkaline hydrogen pero...

Embodiment 3

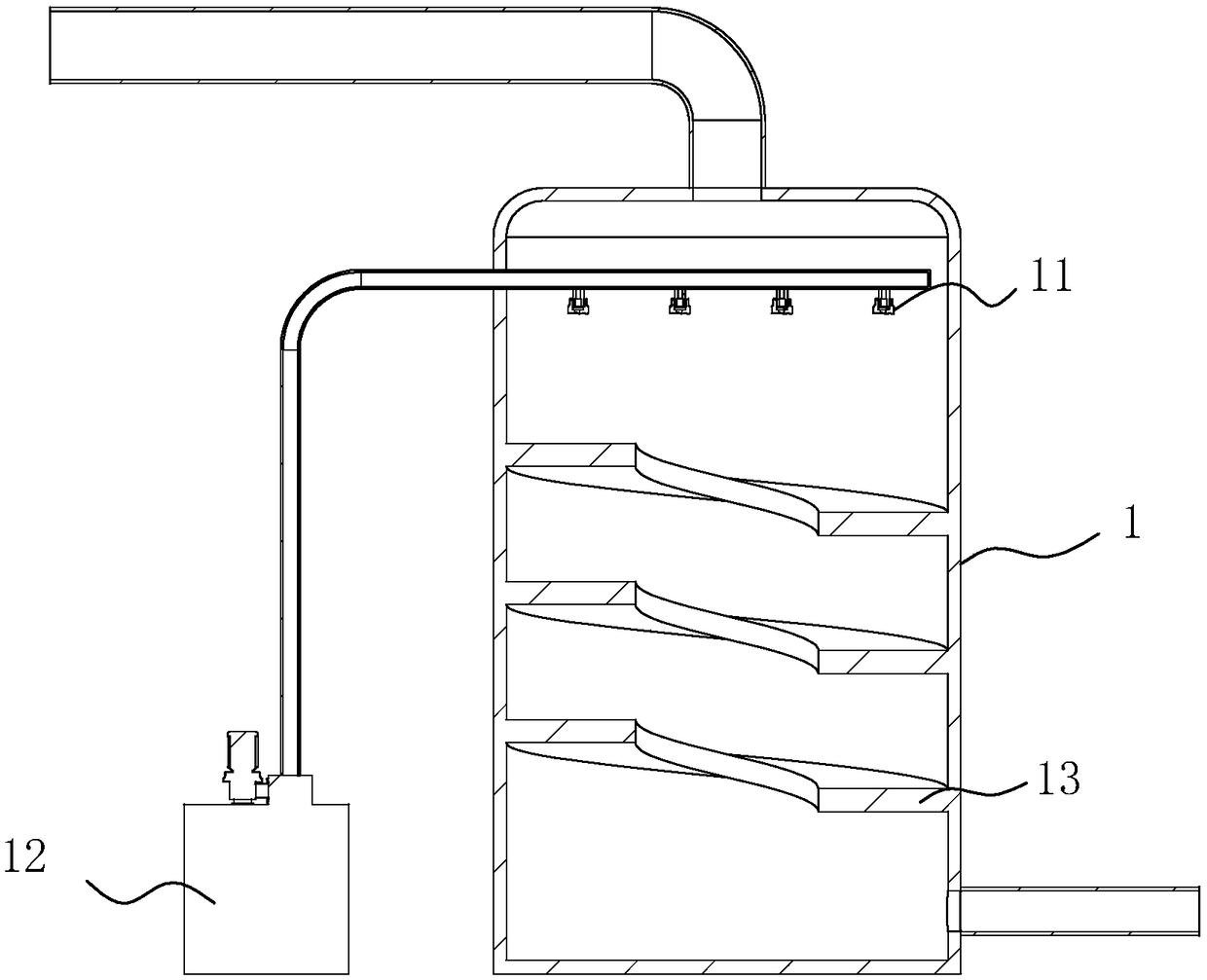

[0050] as attached Figure 5 As shown, a low-temperature plasma exhaust gas treatment system is based on the second embodiment, and an activated carbon adsorption device 4 is also arranged between the plasma purification device 2 and the chimney 3 . Among them, as attached Figure 6 As shown, the air inlet of the activated carbon adsorption device 4 has several baffles 41 inclined downwards, and the baffles 41 are arc-shaped. In this way, the exhaust gas after passing through the plasma purification device 2 will first pass through the baffle plate 41, and the water mist in the exhaust gas will condense on the baffle plate 41 during this process, and flow down along the baffle plate 41, thereby effectively improving the baffle plate. 41 service life. Thereby reducing the water content in the exhaust gas, which is beneficial to ensure that the activated carbon is in a dry state for a long time, and then helps to ensure the adsorption performance of the activated carbon for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com