Wiring terminal bending assembly system and method

A terminal and assembly system technology, applied in the field of terminal bending assembly system, can solve the problems of affecting insertion efficiency, poor bending effect, loose plastic core, etc., to improve product quality, ensure reliability, and reliable clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

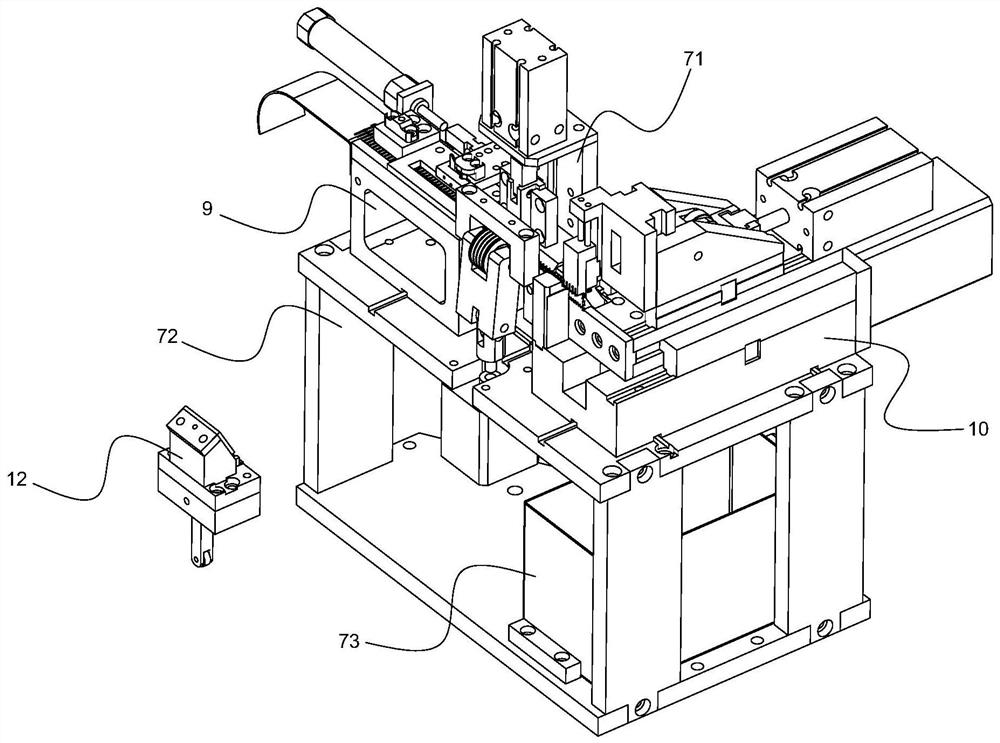

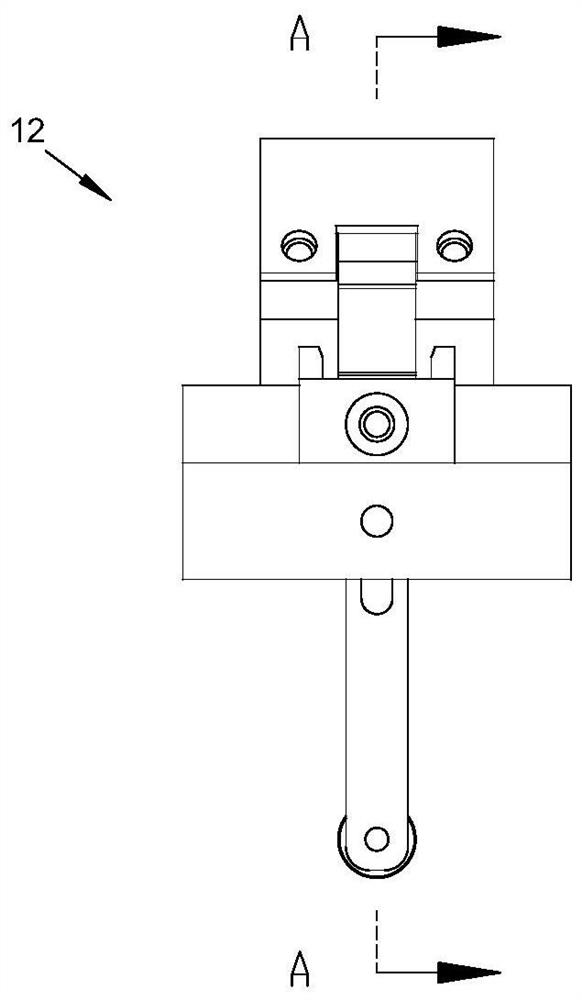

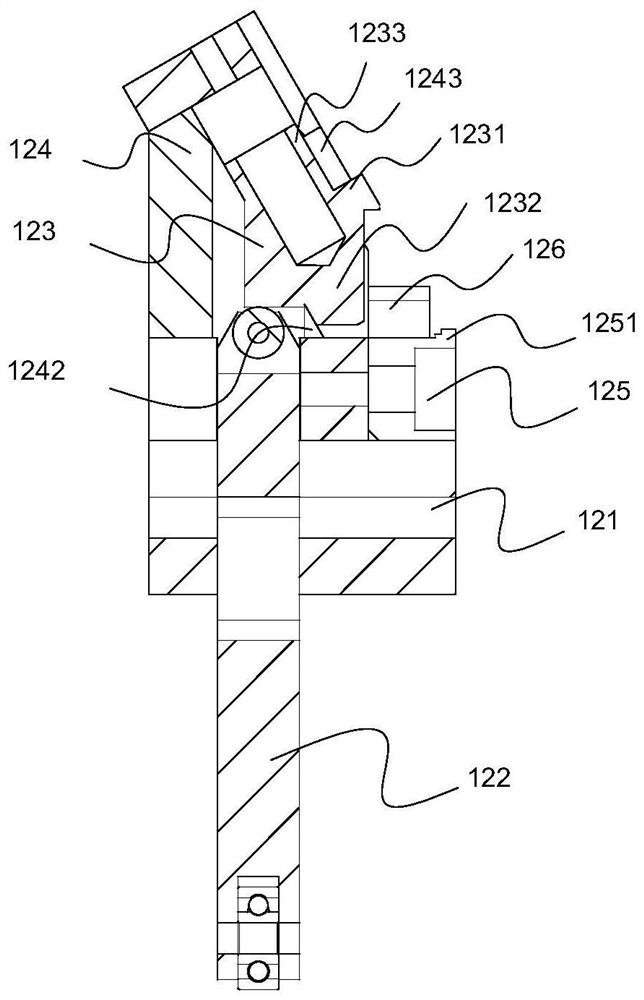

[0031] Such as figure 1 As shown, a terminal bending assembly system includes a clamp 12 and a terminal bending assembly device, and the terminal bending assembly device adopts a terminal bending assembly device. A terminal bending assembly device, the device includes a bending mechanism 71, a support frame 72, a waste collection box 73, a feeding mechanism 9 and an insertion mechanism 10; the feeding mechanism 9, the bending mechanism 71 and the insertion mechanism 10 are sequentially installed on the support On the upper end surface of the frame 72, a waste collection box 73 is provided below the insertion mechanism 10; the feeding mechanism 9 sends the terminals to the bending mechanism 71 one by one; the bending mechanism 71 bends the terminals, and the terminals enter and insert after bending. In the mechanism 10; the insertion mechanism 10 first cuts the terminal to separate the waste, and the waste enters the waste collection box 73; then the insertion mechanism 10 inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com