Electronic cigarette atomizer

An electronic cigarette atomizer and atomization technology, applied in tobacco and other directions, can solve the problems of ultrasonic atomization sheet affecting atomization efficiency, affecting smoke volume and smoke taste, poor user experience, etc., to improve smoke taste, smooth replacement, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

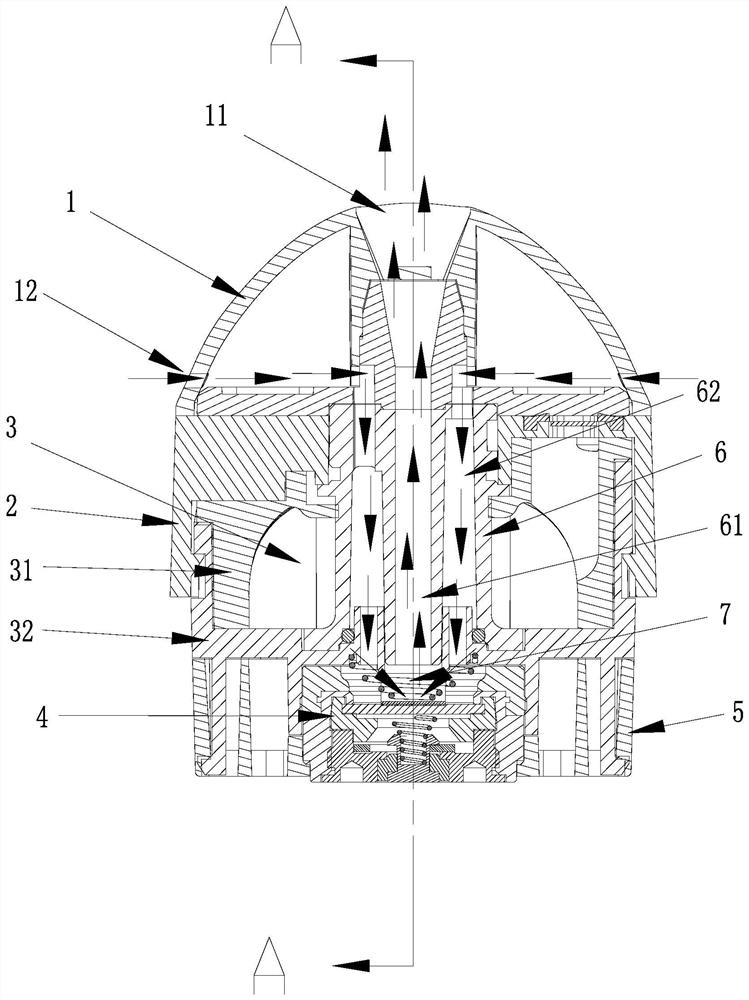

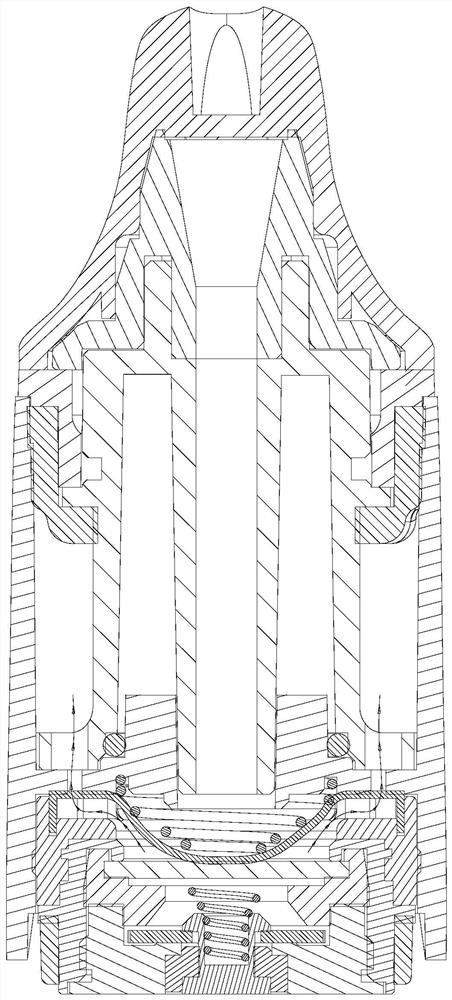

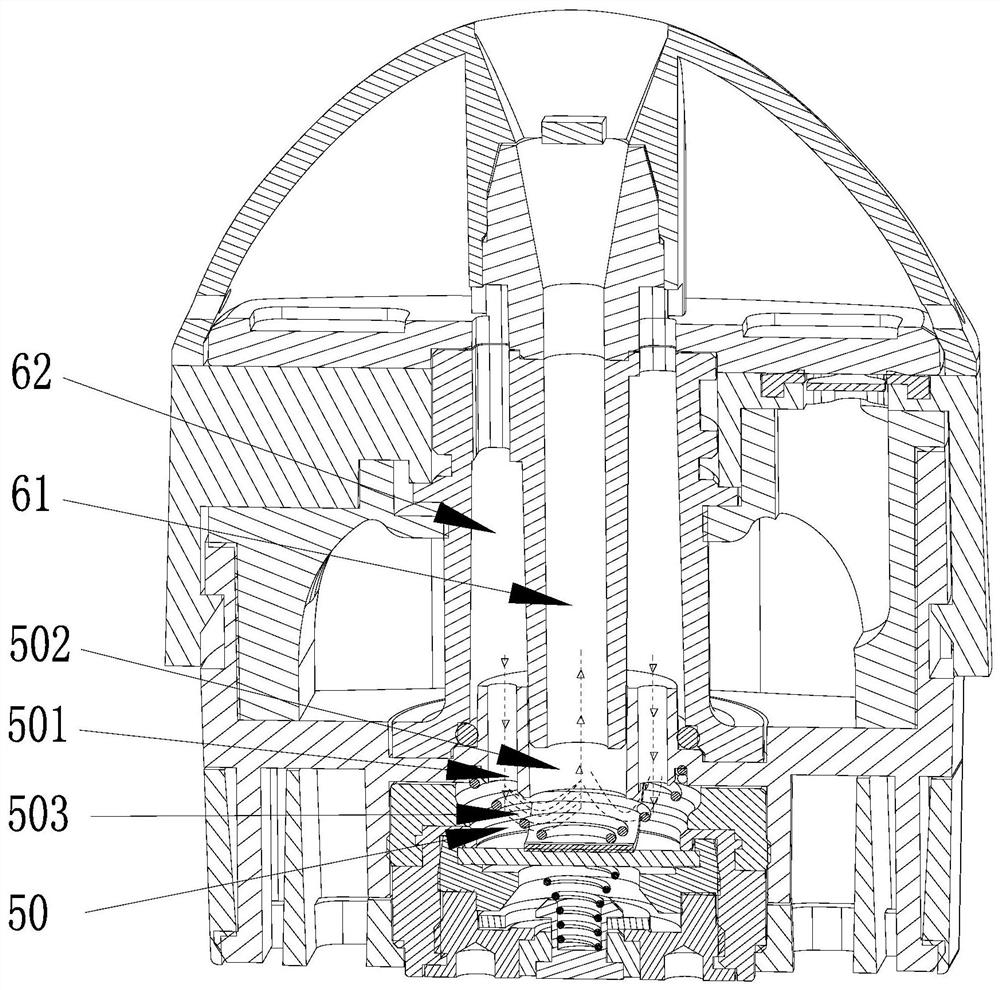

[0044] Such as figure 1 - Figure 12 As shown, an embodiment of the electronic cigarette atomizer of the present invention includes a nozzle device 1 , an oil tank device 3 and an atomizing core 4 . A suction nozzle 11 and an air inlet 12 are arranged on the suction nozzle device 1 . The oil tank device 3 is formed by interlocking an oil tank inner shell 31 and an oil tank outer shell 32 , and an oil outlet 321 is provided at the bottom of the oil tank shell 32 . The upper cover of the oil tank inner shell 31 and the oil tank shell 32 is provided with a gland 2, the bottom of the oil tank shell 32 is provided with a hook 322, the bottom cover 5 is provided with a draw groove 51 matched with the hook 322, and the middle part of the bottom cover 5 is locked. The atomizing core 4 is fixed, and the hook 322 of the oil tank shell 32 is inserted into the slot 51 of the bottom cover 5, not only the oil tank device 3 and the bottom cover 5 are clamped and fixed, but also the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com