Dead angle part cleaning mechanism based on computer case cleaning

A technology of cleaning mechanism and computer, which is applied to cleaning equipment, cleaning methods and utensils, cleaning methods using tools, etc. and other problems to achieve the effect of extending the cleaning distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

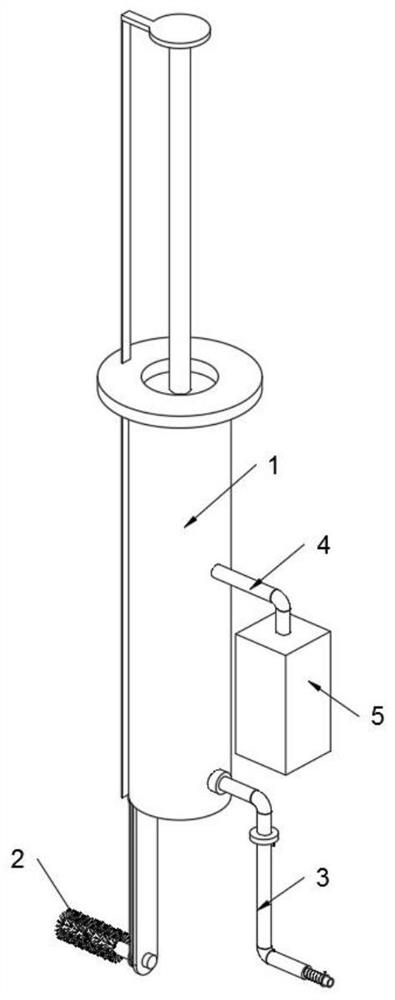

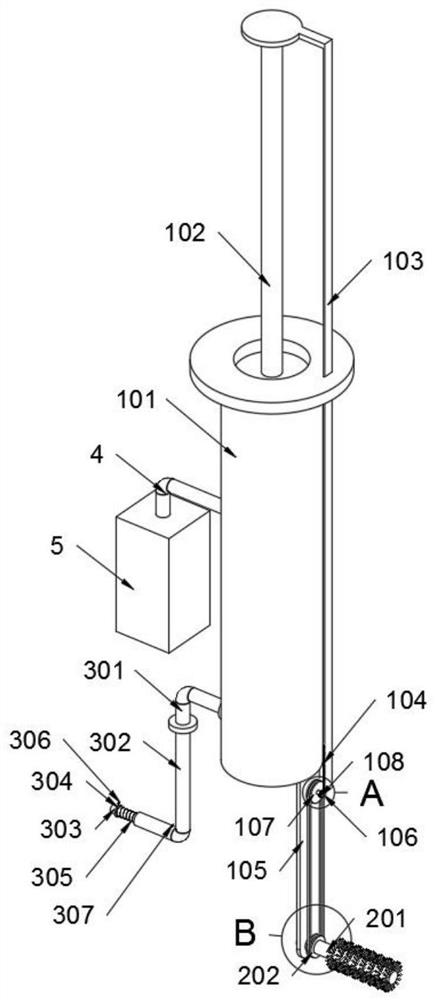

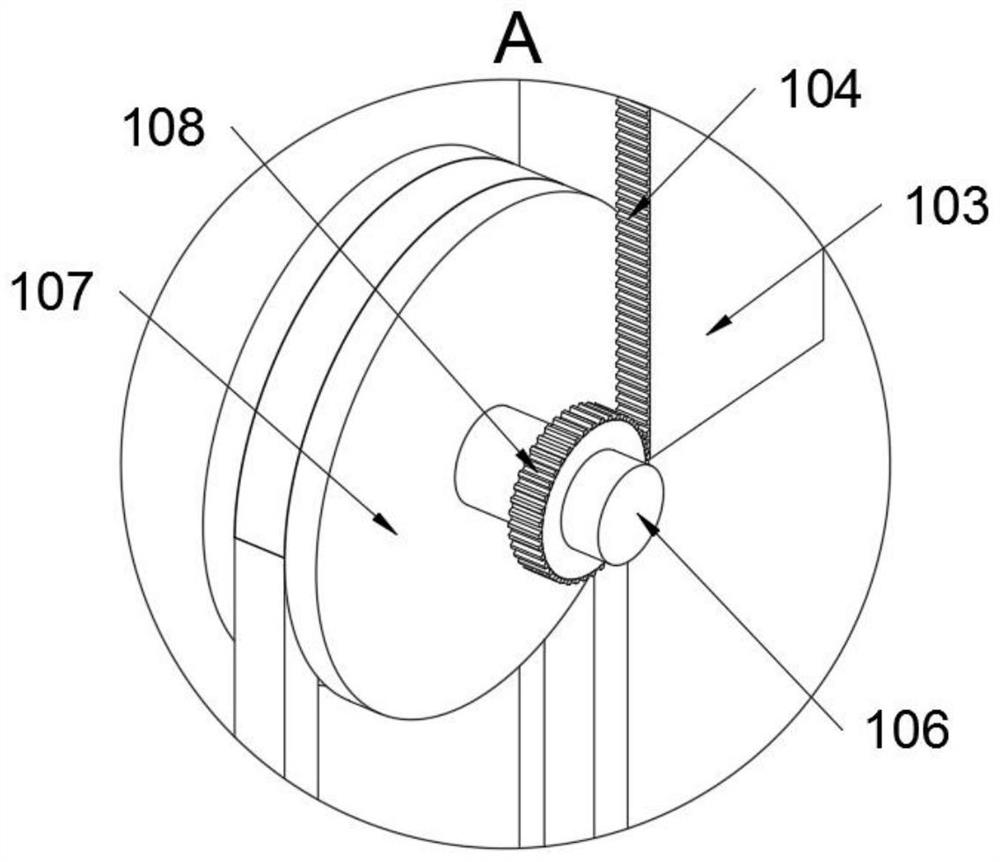

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a cleaning mechanism for dead spots based on computer case cleaning, which includes an injection structure 1; There is an exhaust pipe 4; the exhaust pipe 4 is connected with a purification box 5; refer to as Figure 8 The dust suction pipe structure 3 includes a connecting pipe 301, a dust suction pipe main body 302, a reinforcing pipe 303, a retaining ring 304 and an elastic member 305, the connecting pipe 301 is welded on the cylinder body 101, and the connecting pipe 301 communicates with the cylinder body 101, And the head end of the connecting pipe 301 is rotatably connected with a dust suction pipe main body 302; a strengthening pipe 303 is slidably connected in the dust suction pipe main body 302, and a retaining ring 304 is welded on the strengthening pipe 303; the outer wall of the strengthening pipe 303 is sleeved with a The elastic piece 305, and the elastic piece 305 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com