Fixture for machining shroud of engine blade and machining method of engine blade

An engine blade and processing method technology, applied in metal processing mechanical parts, manufacturing tools, metal processing equipment and other directions, can solve the problem of unguaranteed blade crown quality, shorten the processing process, improve the detection accuracy, and is not easy to twist or the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

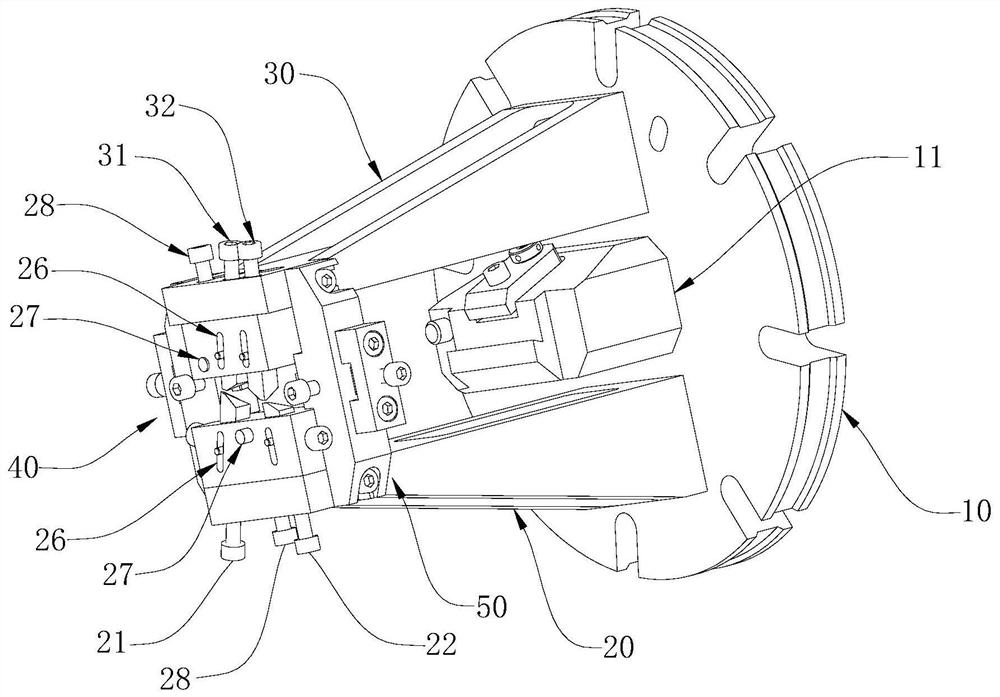

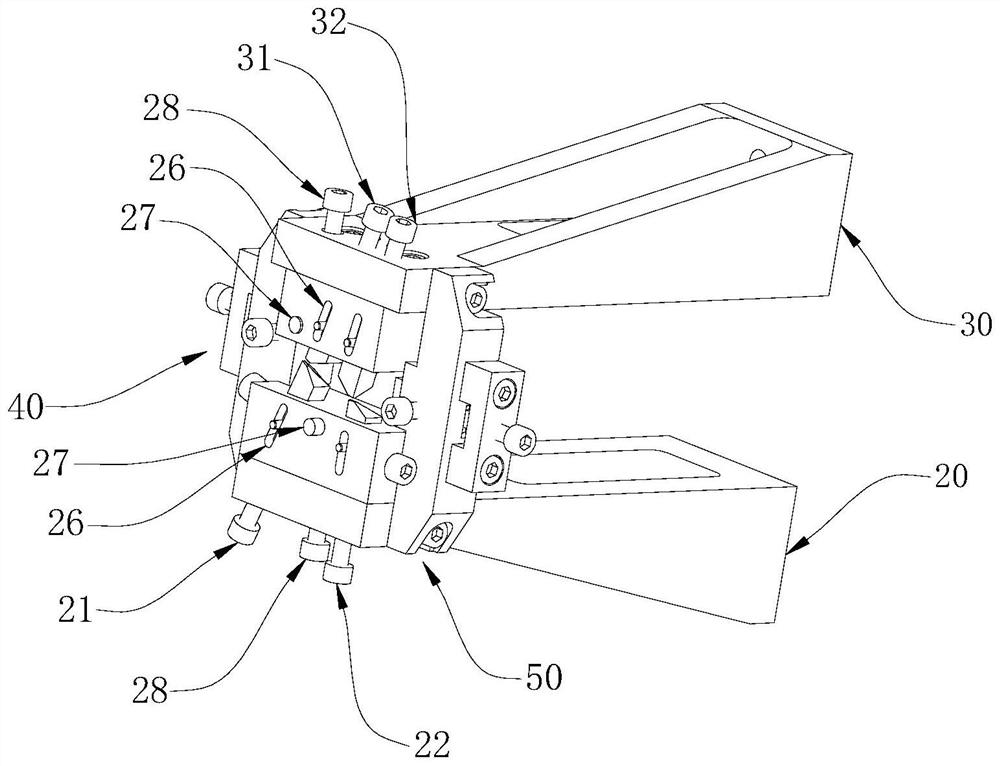

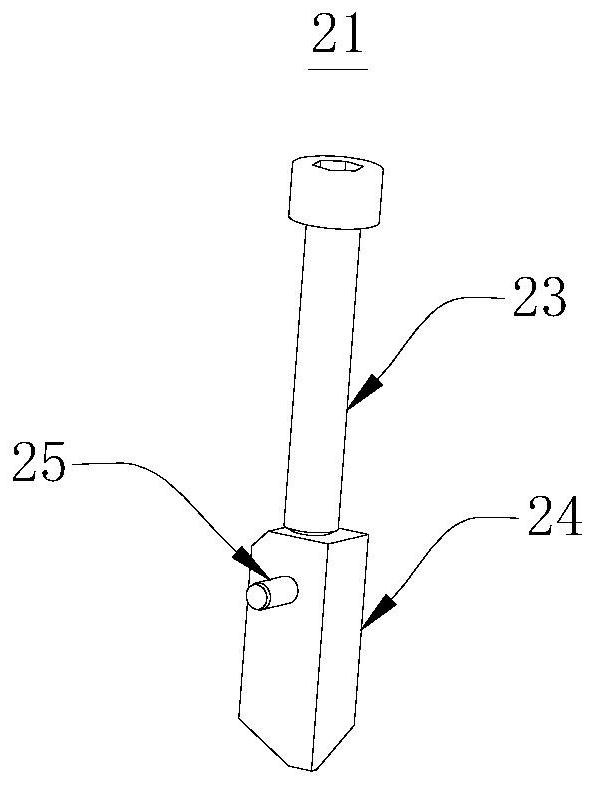

[0052] The jig for machining the crown of the engine blade includes: a first support block 20 and a second support block 30 , the first support block 20 and the second support block 30 are perpendicular to the machine tool positioning plate 10 and installed on the machine tool positioning plate 10 . The structure of the first support block 20 and the second support block 30 is consistent, and the first support block 20 and the second support block 30 are oppositely arranged on both sides of the jaw 11 on the machine positioning plate 10, the first support block 20 and the second support block Each block 30 includes a connecting end connected to the machine tool positioning plate 10 through bolts and a positioning end away from the machine tool positioning plate 10 . The positioning end of the first support block 20 is used to cooperate with the convex surface of the blade airfoil, and the convex surface of the blade airfoil is limited, and the positioning end of the second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com