A water surface model forced roll test device

A test device and rolling technology, which is applied to the field of forced rolling test devices for water surface models, can solve the problems of measurement data error, large sinusoidal motion trajectory error, etc., and achieve the effects of improving test accuracy, reducing intermediate links and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

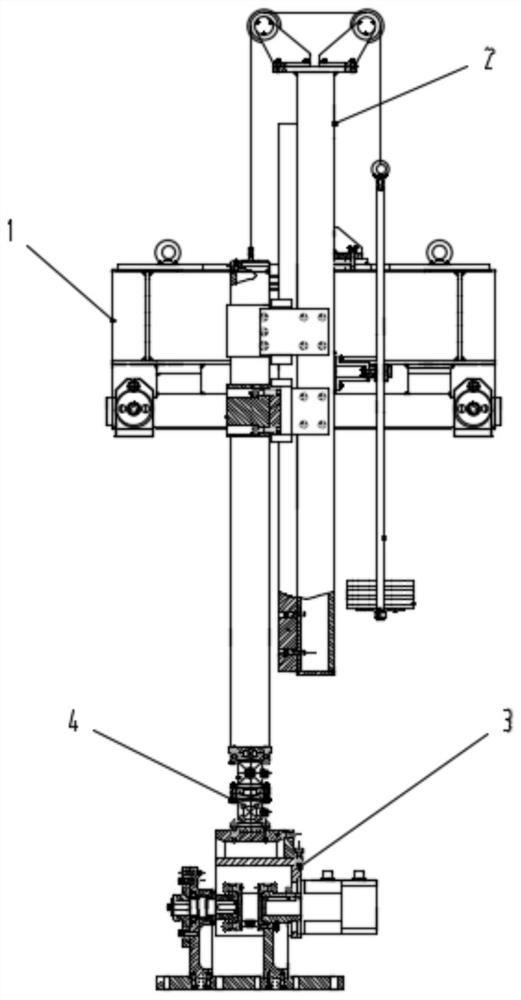

[0038] Such as Figure 1-Figure 8 As shown, the water surface model forced rolling test device of this embodiment includes a mounting base 1, a hole is opened in the middle of the mounting base 1, a vertical oscillation mechanism 2 is installed in the hole, and the bottom of one end of the vertical oscillation mechanism 2 passes through The combined sensor 4 is connected to the combined pitch and roll mechanism 3 .

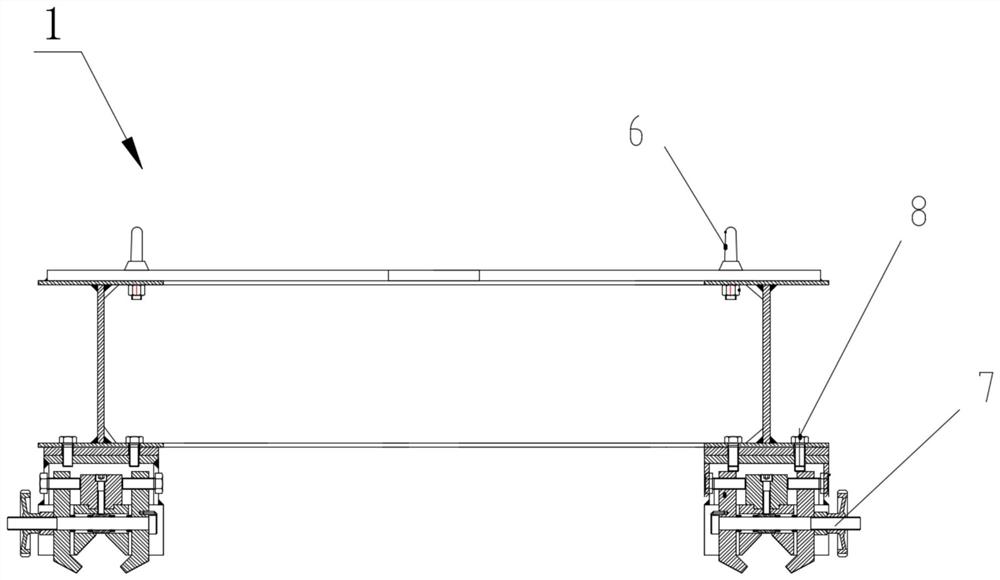

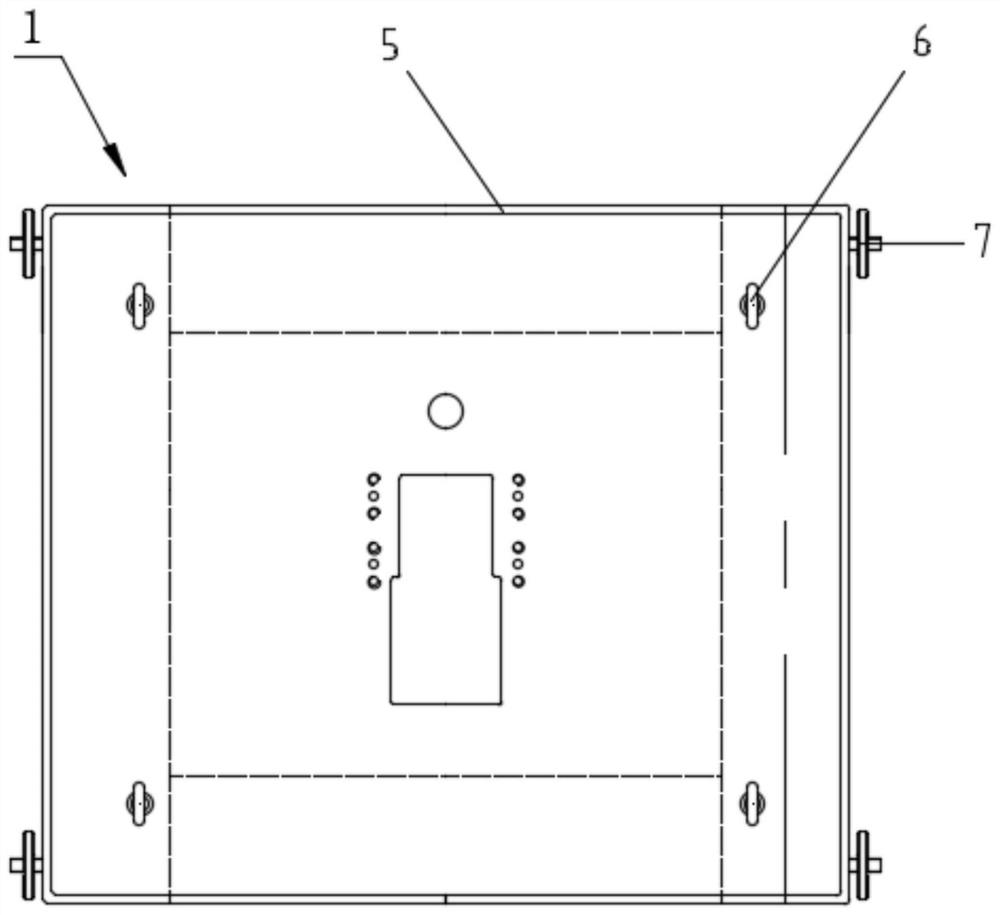

[0039] The structure of the installation base 1 is: including a base frame 5, the base frame 5 is a frame structure, the four corners of the upper surface of the base frame 5 are respectively equipped with eyebolts 6, and the four corners of the lower surface of the base frame 5 are respectively passed through The first fixing screw 8 is fixed with the locking mechanism 7 .

[0040] The structure of the locking mechanism 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com