Plant aromatic essential oil preparation and extraction process

A technology for aromatic essential oils and plants, which is applied in the field of preparation and extraction of plant aromatic essential oils, can solve the problems of uneven filling amount, rupture of a separatory funnel, influence on the full mixing of oil-water mixture, etc., and achieves the effect of avoiding rupture and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

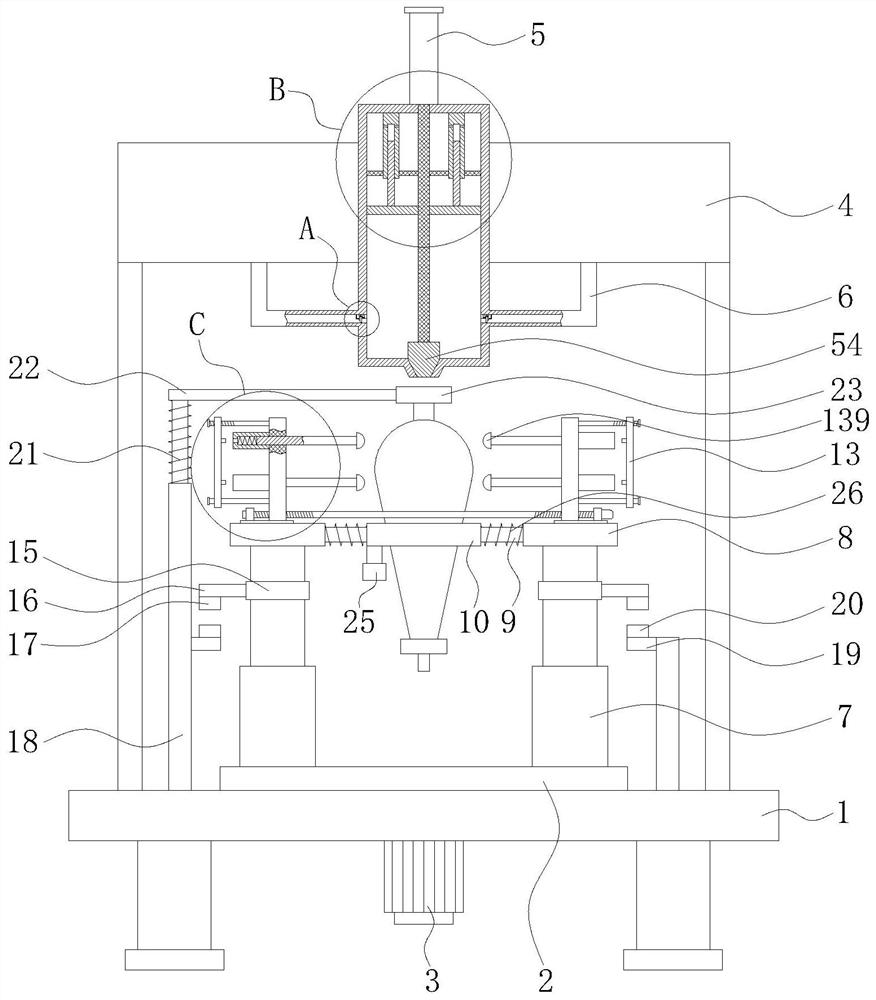

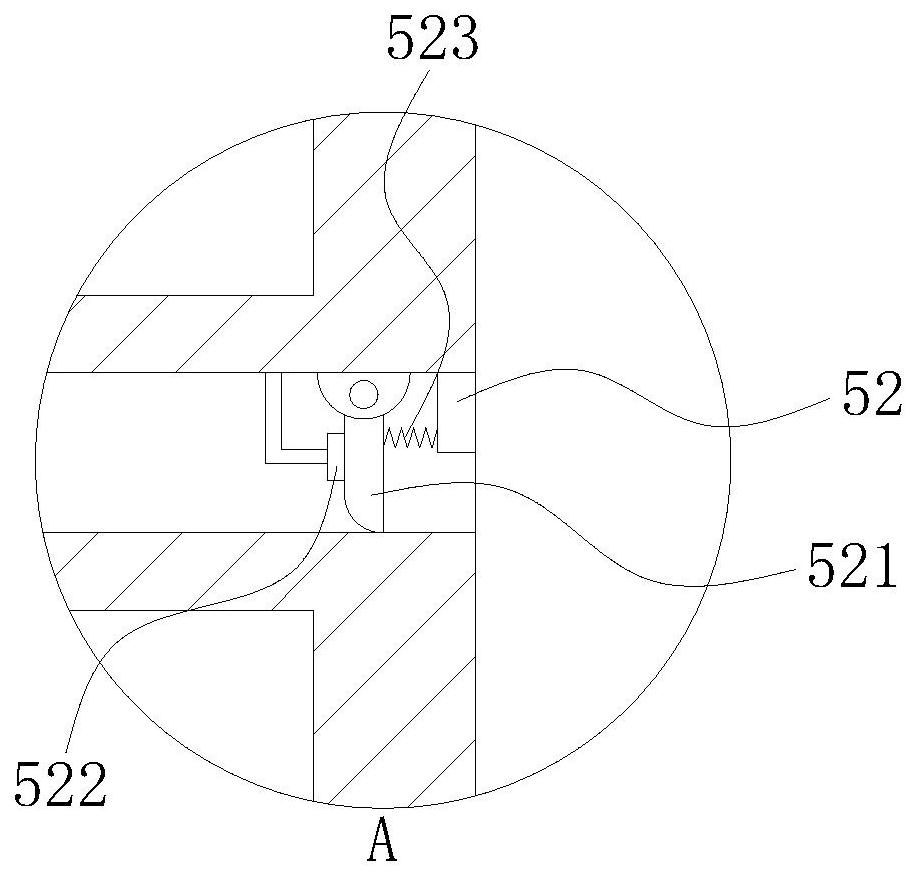

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

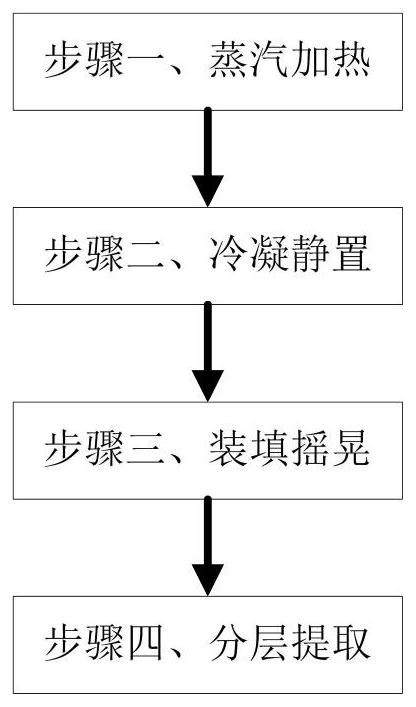

[0034] Such as figure 1 As shown, the present embodiment provides a preparation and extraction process of plant aromatic essential oil, comprising the following steps:

[0035] Step 1. Steam heating: put the plants containing aromatic substances into the still, and inject water vapor into the bottom of the still.

[0036] Step 2, condensing and standing still: the water vapor mixed with aromatic essential oil components is passed into the condenser, and the oil-water mixture is obtained by standing still.

[0037] Step 3, filling and shaking: fill the oil-water mixture into the separating funnel, and then shake the separating funnel.

[0038] Step 4, layered extraction: put the shaken separatory funnel to rest, and perform layered extraction after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com