Assembly type decoration integrated partition wall system assembly and installation method

An installation method and prefabricated technology, applied in the direction of walls, floors, electrical components, etc., can solve the problems of many processes, troublesome non-standard connections, and heavy weight of slatted partitions, etc., and achieve the effect of less processes and less impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

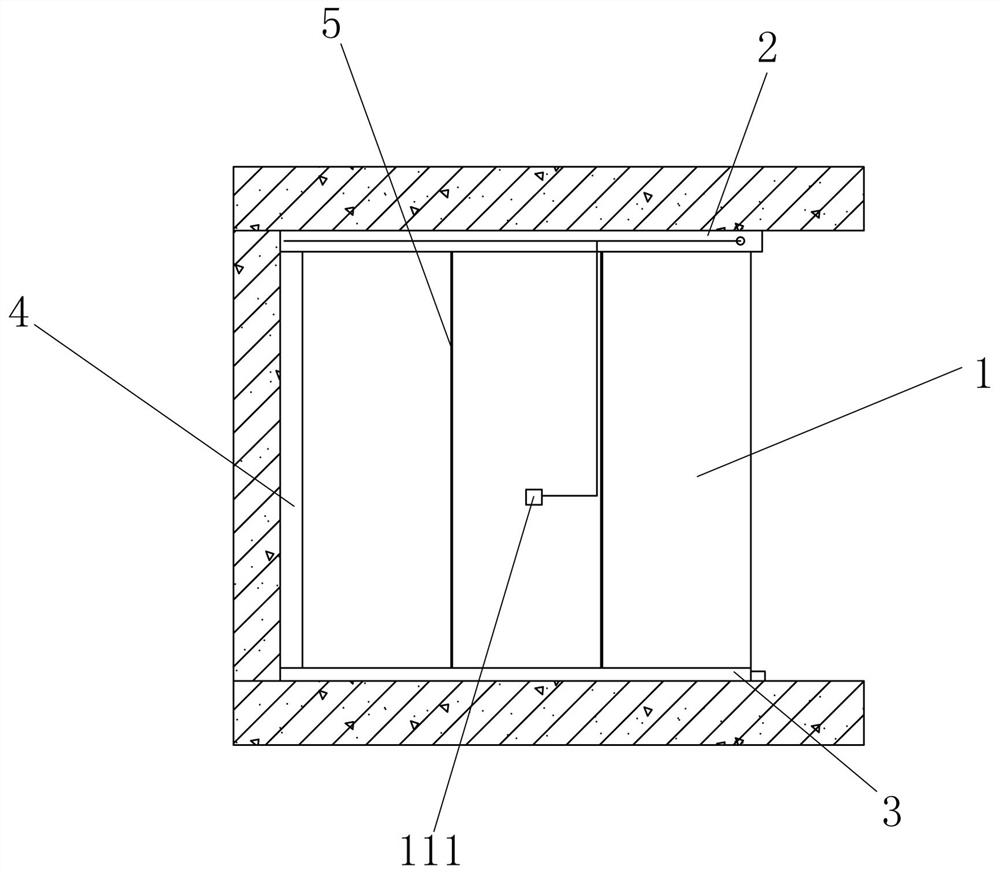

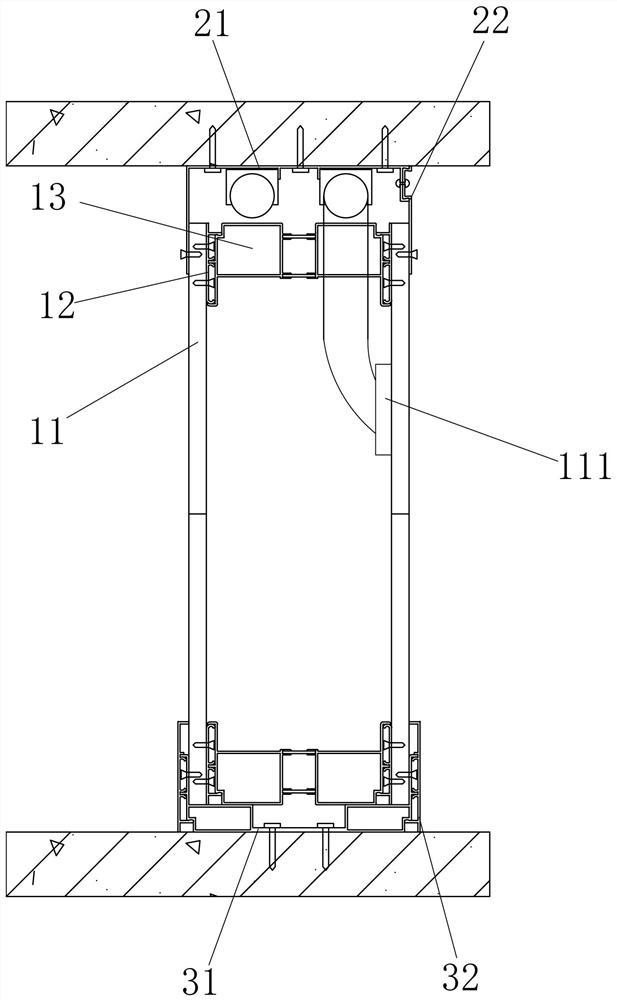

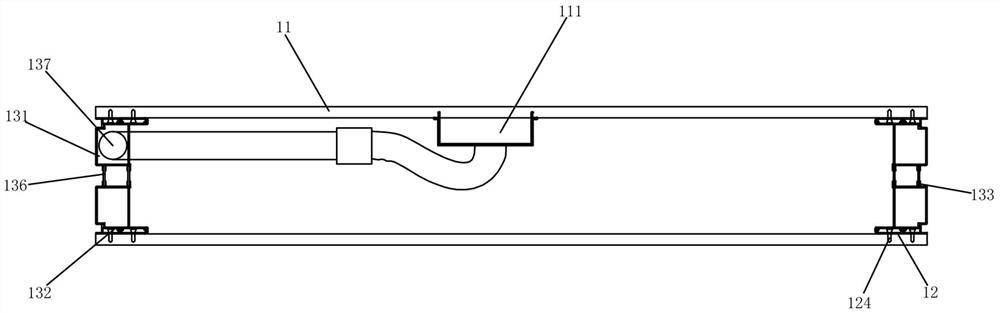

[0050] Embodiment one: if Figures 1 to 10 As shown, it is only one of the embodiments of the present invention, a prefabricated decorative integrated partition wall system assembly, including a top integrated device 2 connected to the top of the wall, a bottom integrated device 3 connected to the ground, and a The integrated wall panel 1 between the top integrated device 2 and the bottom integrated device 3, the integrated wall panel 1 includes a broken bridge keel 13 and a decorative panel 11, and the top integrated device 2 includes a top keel base 21 and a top keel cover plate 22, the bottom integrated device 3 includes a bottom keel base 31 and a bottom keel cover plate 32, the top keel base 21 is provided with a cable pipe clamp, and the bridge break keel 13 is provided with a wiring post 131 and a set In the wiring pipe 137 inside the wiring post 131 , the integrated wiring block 111 is arranged on the decorative panel 11 .

[0051] In the present invention, the top of...

Embodiment 2

[0065] Embodiment two, still as Figures 1 to 10As shown, it is only one of the embodiments of the present invention. On the basis of the first embodiment, in a prefabricated decorative integrated partition wall system assembly, the number of the rubber plate 136 is at least one. Of course, the rubber plate card The number of slots 133 is at least one, that is to say, each wiring column 131 is provided with a plurality of rubber plate slots 133, so that a plurality of rubber plates 136 can be connected between two wiring columns 131, and two wiring columns 131 can be connected. The stability between the wire posts 131 is better, and the veneer 11 is an 8mm inorganic non-metal strip veneer, which is light in weight and high in strength, and can be used for dry work.

[0066] The number of said draw-in slots 213 is at least one, that is to say, a plurality of draw-in slots 213 can be provided on the top keel base 21; At least one, a plurality of nail-holding grooves 222 are con...

Embodiment 3

[0072] Embodiment three, such as Figure 11 , 12 As shown, the present invention also provides an installation method of a prefabricated decorative integrated partition wall system assembly in the above embodiment, including the following steps:

[0073] S1: Set the bottom keel base for installing the bottom integrated device on the ground, and set the top keel base for installing the top integrated device above the bottom integrated device;

[0074] S2: Install the line pipe card on the top keel base, lay the pipeline on the line pipe card, and reserve the transfer line;

[0075] S3: After the integrated wall panel is assembled, it is set and installed between the bottom integrated device and the top integrated device for fixing;

[0076] S4: The integrated wiring block on the integrated wall board is connected to the transfer line of the pipeline on the top keel base through the wiring tube of the wiring post;

[0077] S5: Position and install the top keel cover plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com