Assembly type decoration integrated partition wall integration device

An integrated device and prefabricated technology, applied in the direction of walls, floors, electrical components, etc., can solve the problems of large impact on site environment and working hours, many processes, construction cycle of wet work, etc. The effect of less and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

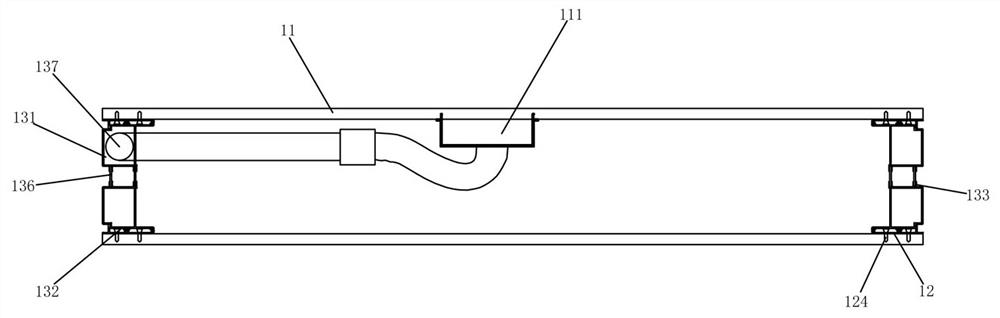

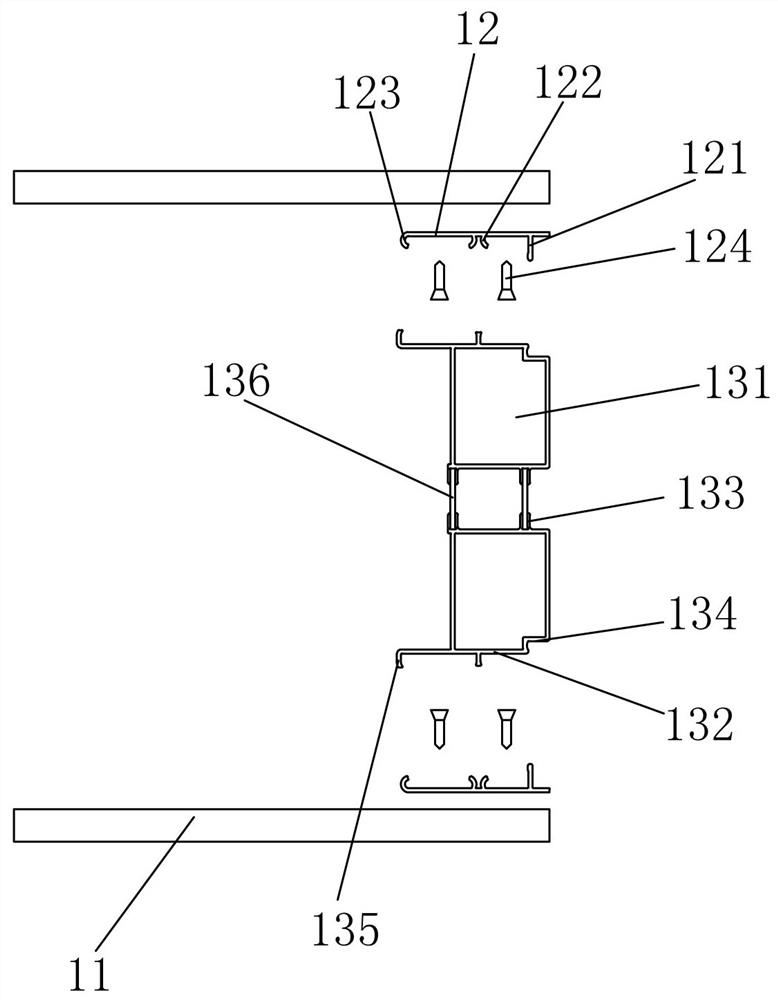

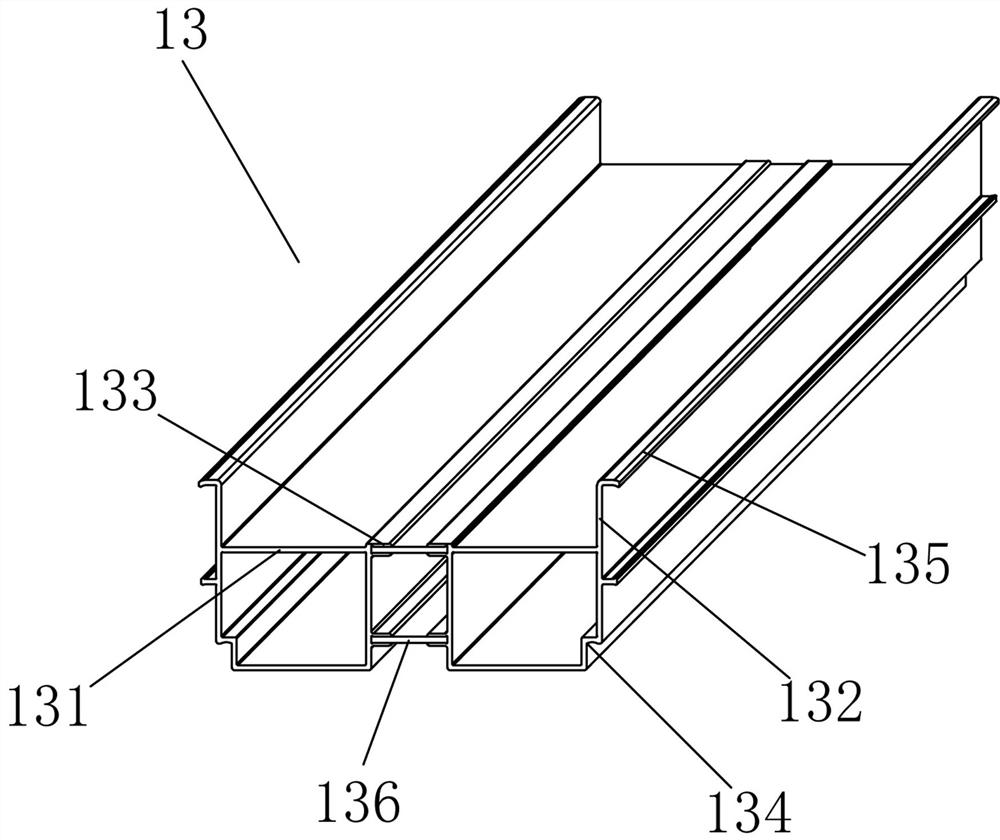

[0038] Embodiment one: if Figures 1 to 4 As shown, it is only one of the embodiments of the present invention, a prefabricated decorative integrated partition wall integration device, including a decorative panel 11, an assembly plate 12 connected with the decorative panel 11, and an assembly plate 12 connected Broken bridge keel 13, the broken bridge keel 13 includes a wiring column 131 and a side panel 132 connected to the side of the wiring column 131, and a rubber plate is provided on the side of the wiring column 131 away from the side panel 132 A card slot 133, the bottom end of the side panel 132 is provided with a card slot 134, and the side panel 132 is provided with a raised card bar 135 extending away from the direction of the wiring column 131, the wiring column 131 The number is two, and the two wiring posts 131 are connected by a rubber plate 136. At least a part of the rubber plate 136 is located in the rubber plate slot 133, and the assembly plate 12 is sequen...

Embodiment 2

[0046] Embodiment two, still as Figures 1 to 4 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a prefabricated decorative integrated partition wall integration device of the present invention, the number of the rubber plate 136 is at least one. Of course, the rubber plate 136 The number of board slots 133 is at least one, that is to say, each wiring post 131 is provided with multiple rubber board slots 133, so that a plurality of rubber boards 136 can be connected between two wiring posts 131, and two The stability between the two routing columns 131 is better.

[0047] And, the side of the clamping groove 134 is provided with an arc-shaped groove, and the side of the first limiting strip 121 is provided with a convex line matching the arc-shaped groove, so that the first limiting strip 121 and Sides of the locking groove 134 are connected.

[0048] In addition, at least a part of the third limiting strip 123 is arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com