Construction method of waterproof structure of steel structure workshop roof

A technology of waterproof structure and construction method, applied in the direction of roof, roof covering layer, building structure, etc., can solve the problems of waterproof treatment construction, affect the progress of production, inevitable leakage and other problems, achieve good roof insulation effect, easy Operation and reduction of maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

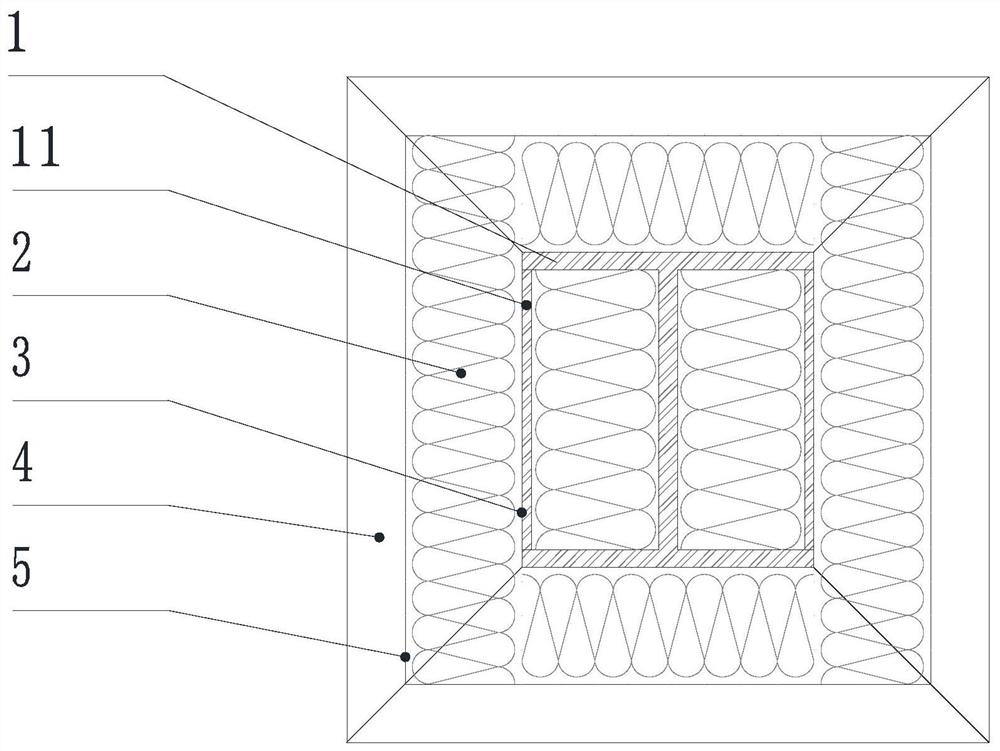

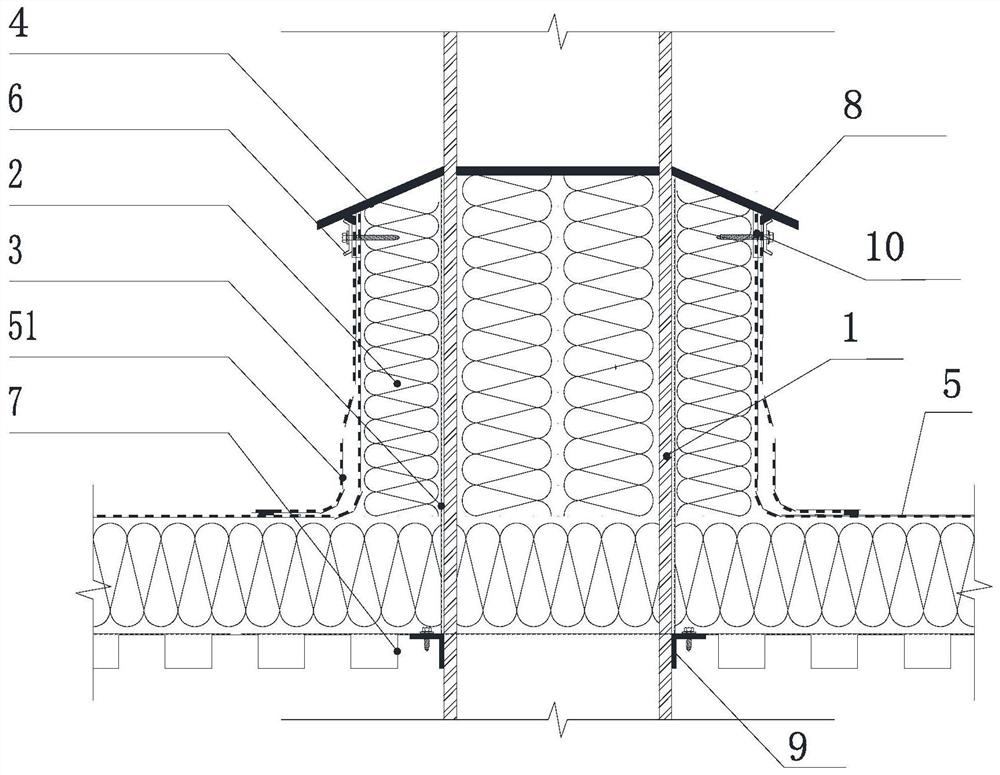

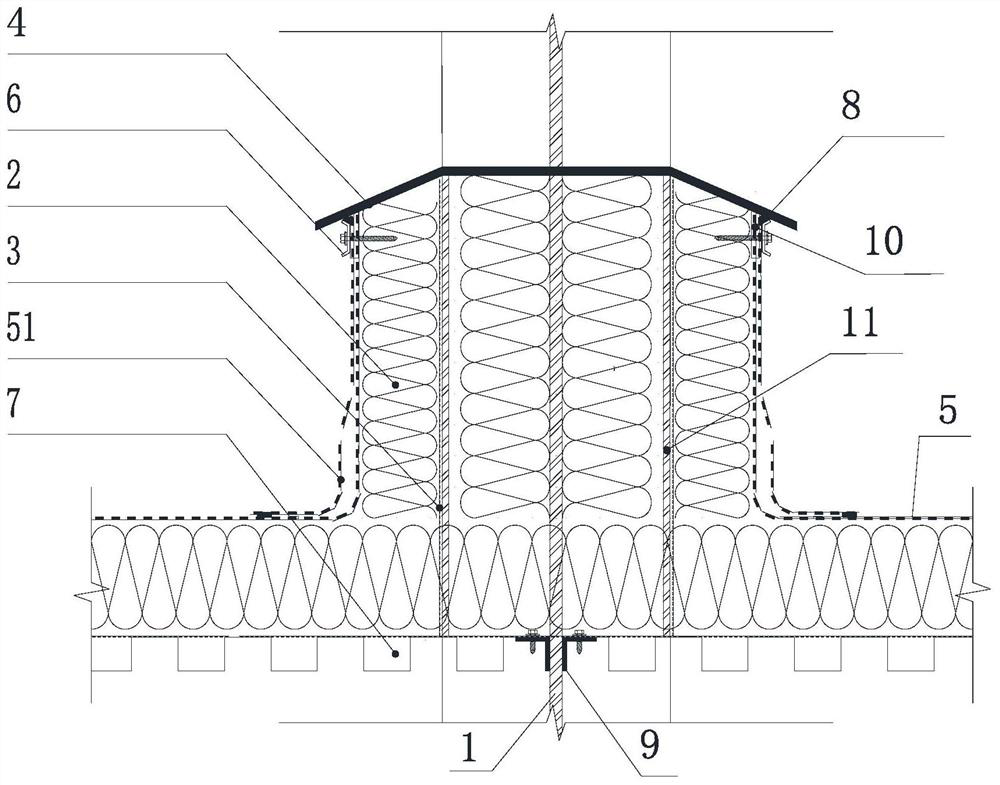

[0029] Please see attached figure 1 to attach image 3 , a construction method for a waterproof structure of a steel structure workshop, comprising the following steps:

[0030] Step 1: Install the reinforcement 9 on the roof member 1 at the elevation of the roof steel bearing plate 7, weld and fix the waterproof cap 4 on the roof member 1, and the waterproof cap 4 is located above the roof steel bearing plate 7.

[0031] The roof member 1 is an I-shaped steel structure, and side panels 11 are respectively welded to the grooves on both sides of the I-shaped steel structure. The height of the side panels 11 is less than the height of the roof member 1, so that the roof member 1 A partially closed box-shaped columnar structure is formed, which is convenient for thermal insulation and waterproof construction.

[0032] Preferably, the side plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com