Socket structure and preparation method thereof

A technology of bundle knots and bamboo strips is applied in the field of bundle knot structures and their preparation, which can solve the problems of unfavorable wide-scale promotion of bamboo composite pipes, restricting the promotion and application of bamboo composite pipes, affecting the normal use of bundle knots, etc. Maintenance cost, improve stability and reliability, and achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

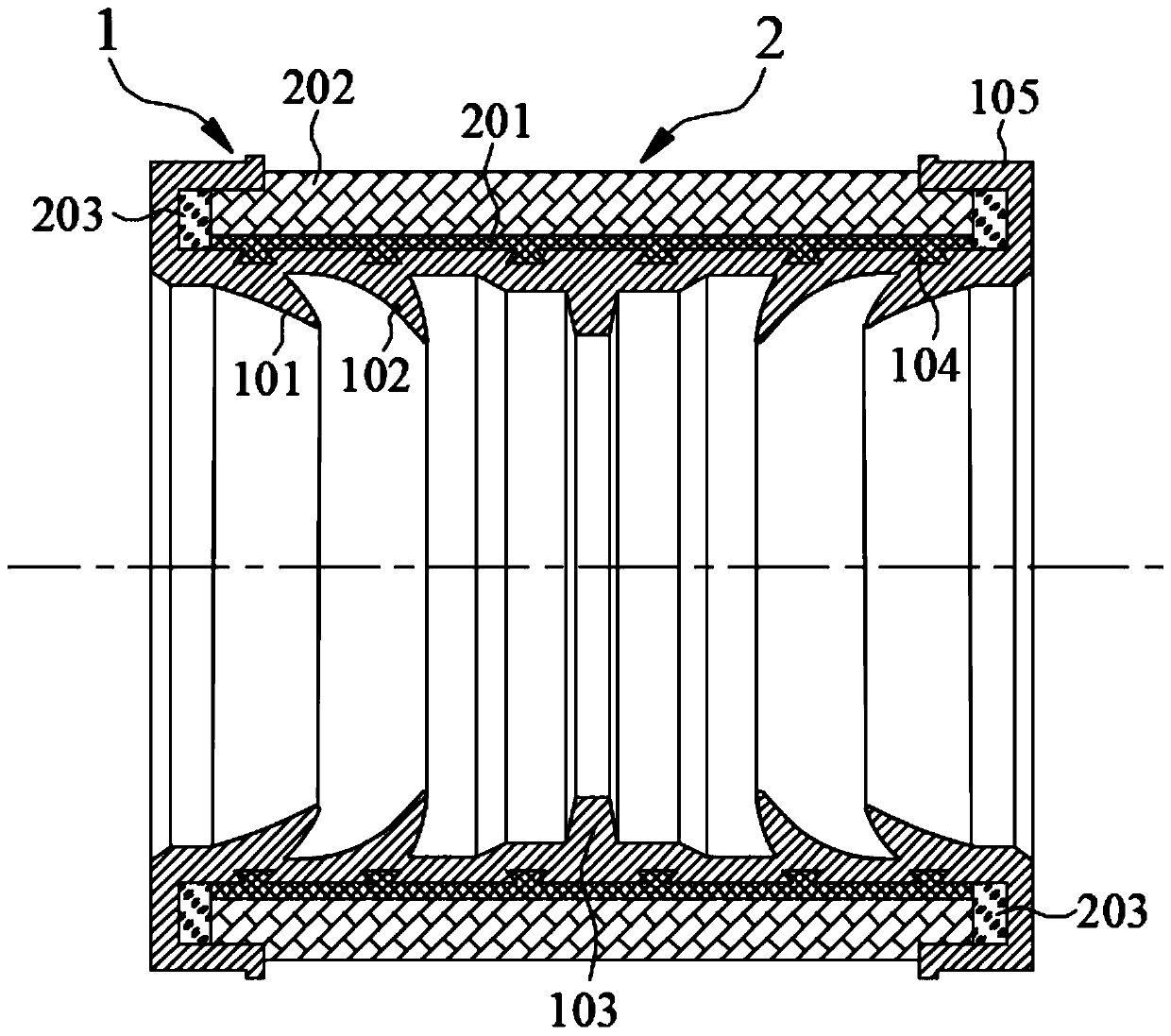

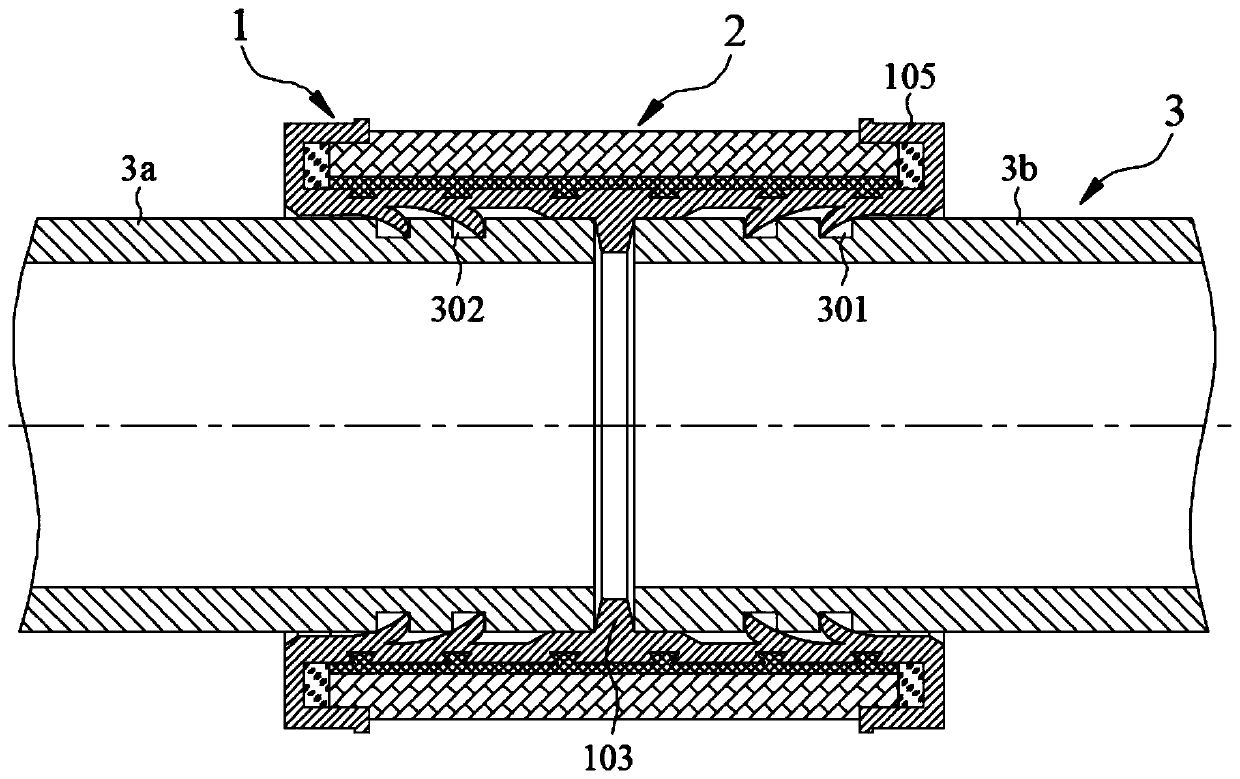

[0040] see figure 1 , 2 , The bundle structure in the preferred embodiment of the present invention is composed of an integral apron 1 and a reinforcing layer 2 . Among them, the integral apron 1 includes a body in a tubular structure, which is made of heat-resistant rubber, has good temperature resistance and certain elastic deformation properties, and each part of the body has a certain thickness in the radial direction , to ensure the stability of its structure. Specifically, it is preferred that the compression rate of the apron in Embodiment 1 is 25%-35%, and the international rubber hardness index (IRHD) of the apron is 45-60.

[0041] Further, a stopper 103 with a certain thickness is arranged on the inner side of the middle part of the body along the ring direction, which is used to abut against the socket ends of the two bamboo composite pipes to be connected, so as to realize the limit of the socket; on both sides of the stopper 103, respectively set There is at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com