Real-time detection method for soft and hard combined stratum distribution area of shield excavation face based on hob rock breaking response

An area-distributed, real-time detection technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems affecting the safety, reliability, and efficient construction of shield tunneling, damage and cracking, and it is difficult to achieve transparent information on the strata that the shield tunnel passes through And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

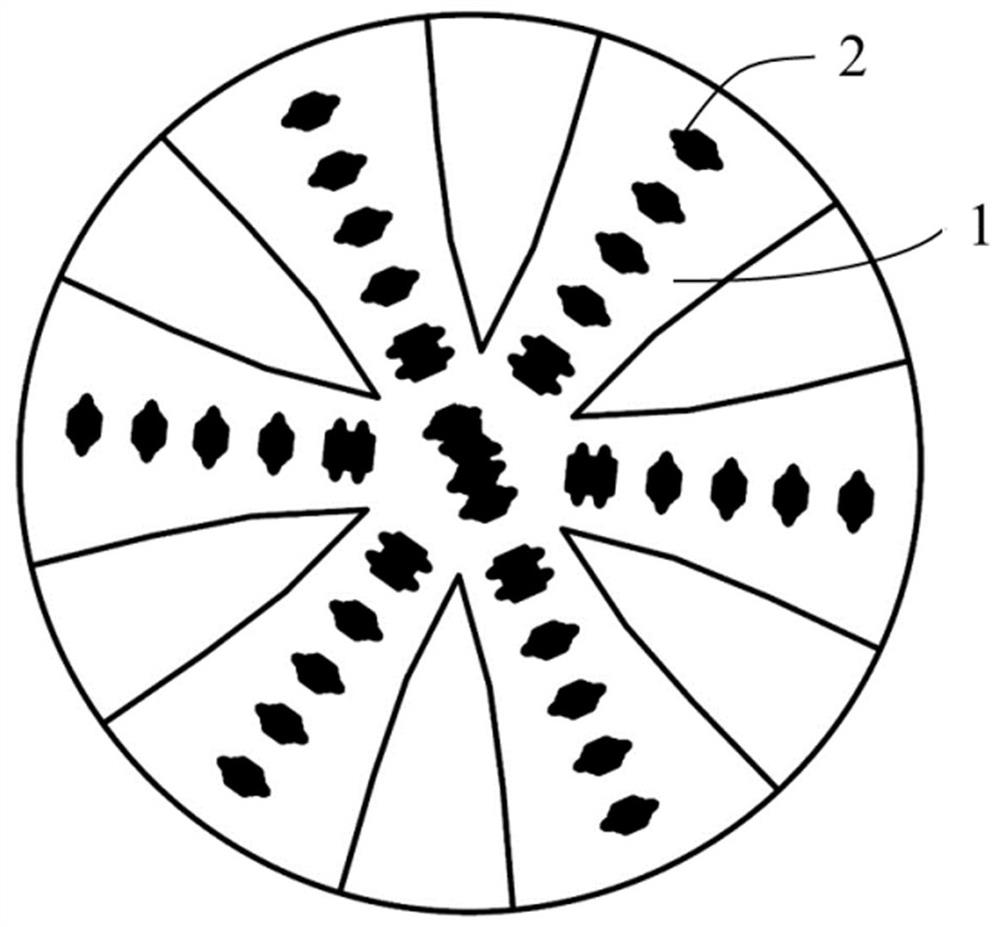

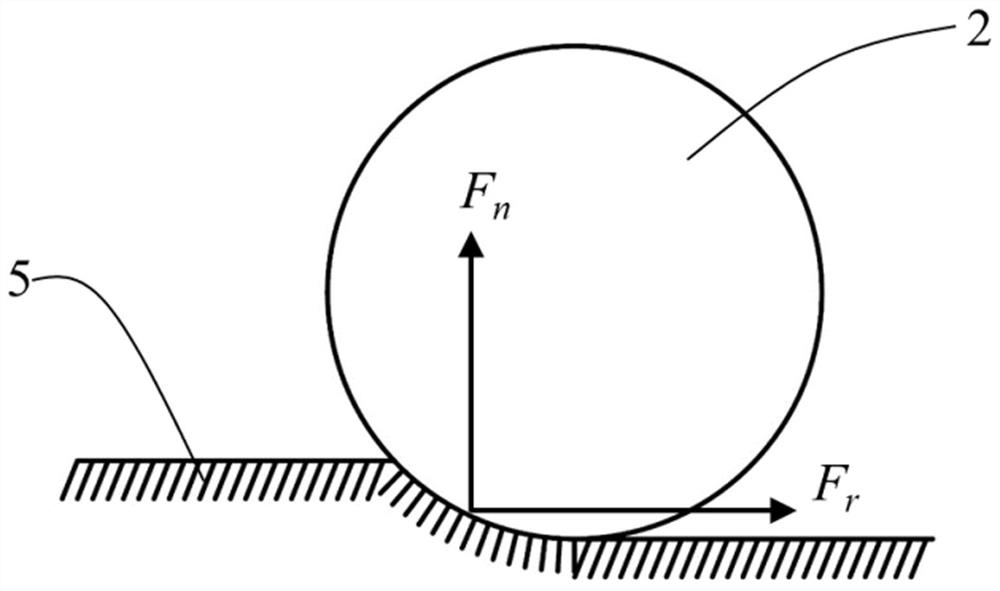

[0029] Example 1: Take the rock-breaking resistance, which is one of the rock-breaking response data of the hob, to illustrate the implementation. According to the characteristics of the difference between the hob's action on soft and hard rock masses, the data collected during the cutter head's rotation can be determined. The distribution area of the soft-hard combination rock mass on the excavation surface, and because the sensor can obtain the rock-breaking resistance of the hob in real time, it is possible to grasp the distribution area of the soft-hard combination rock mass on the excavation surface in real time.

[0030] A real-time detection method for the distribution area of soft and hard combination strata in shield excavation face based on the rock breaking response of the hob, comprising the following steps:

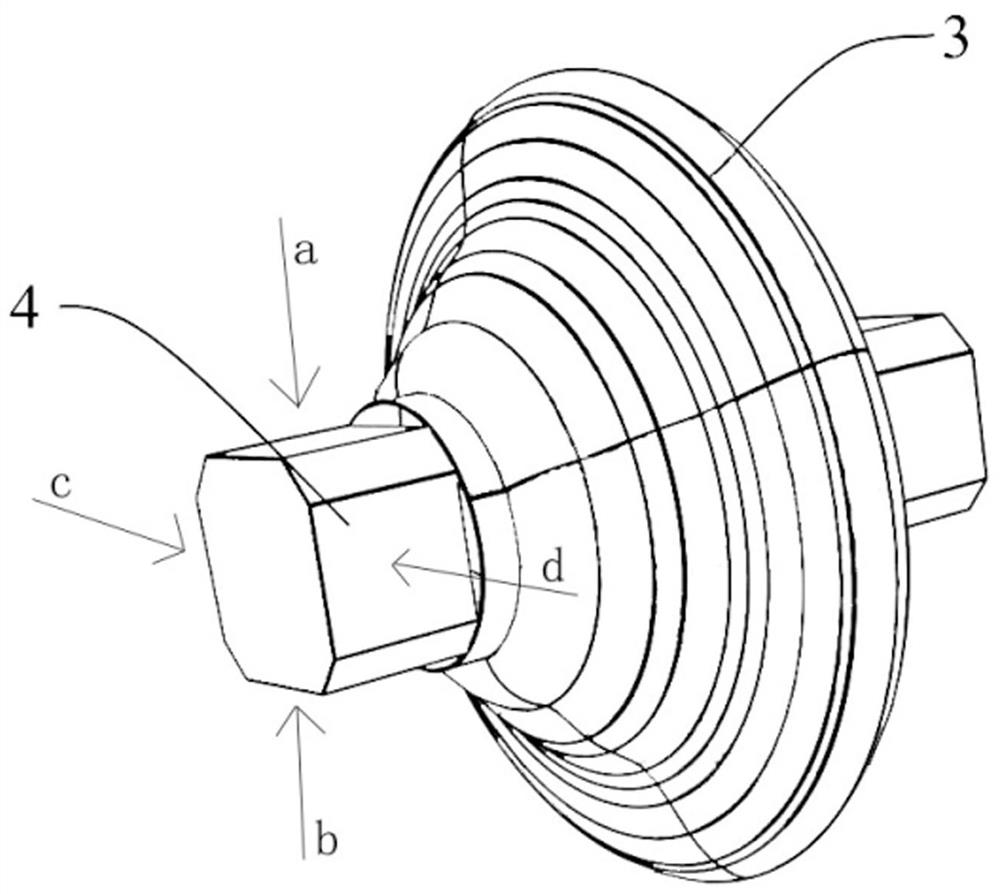

[0031] S1. Sensor installation: Select a sensor of suitable specifications for measuring the rock-breaking resistance data of the hob according to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com