Dust removal device for lithium battery production

A dust removal device and lithium battery technology, which is applied in the direction of combination device, transportation and packaging, and dispersed particle filtration, etc., can solve the problem that the dust removal device is not suitable for lithium batteries, etc., achieve simple structure, improve dust collection quality, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

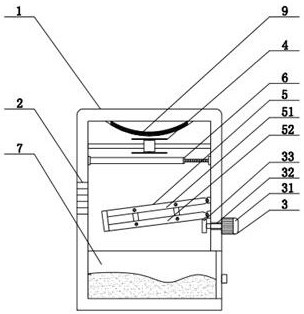

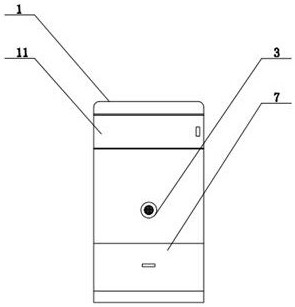

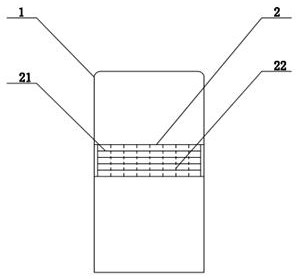

[0016] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a main body 1, a dust suction port 2, a first motor 3, a second motor 4, a sieve tray 5, an isolation plate 6, a dust storage box 7, and an air outlet 8 , filter layer 9; the dust suction port 2 is arranged on the left side of the main body 1, the first motor 3 is arranged on the right side of the main body 1, the second motor 4, the sieve tray 5, the isolation plate 6 and the dust storage box 7 are all Set inside the main body 1, the air outlet 8 is set on the top of the main body 1, the filter layer 9 is set above the second motor 4, the sieve tray 5 includes a first mesh screen 51, a second mesh screen 52, and One end of the first mesh screen 51 is connected to the inner wall of the main body 1 through a hinge, the upper end of the telescopic rod is vertically hinged to the lower end surface of the first mesh screen 51, and the upper end of the second mesh scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com