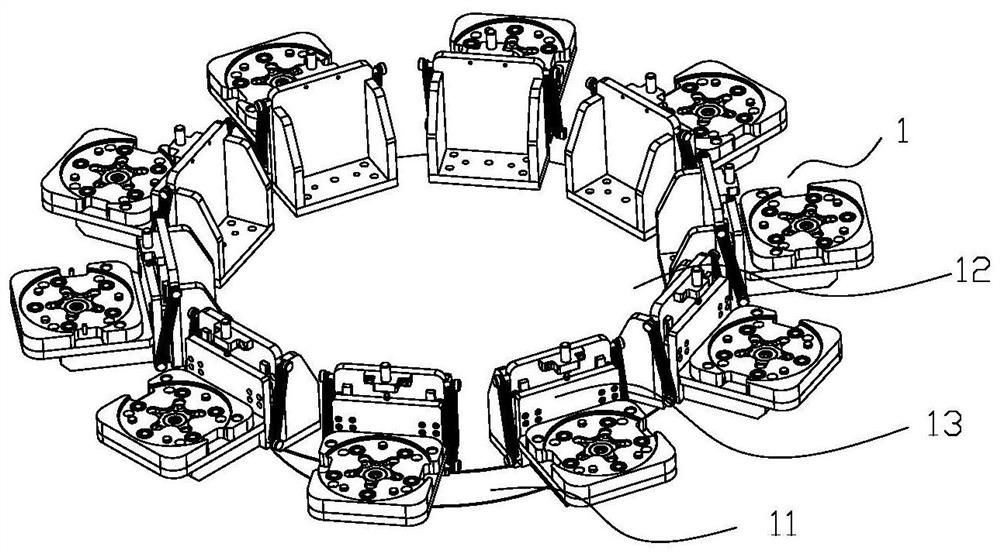

A compressor valve controller indexing plate device

A valve controller and indexing plate technology, applied in the field of compressor production, can solve problems such as poor coordination of indexing plate devices, and achieve the effect of improving the coordination degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

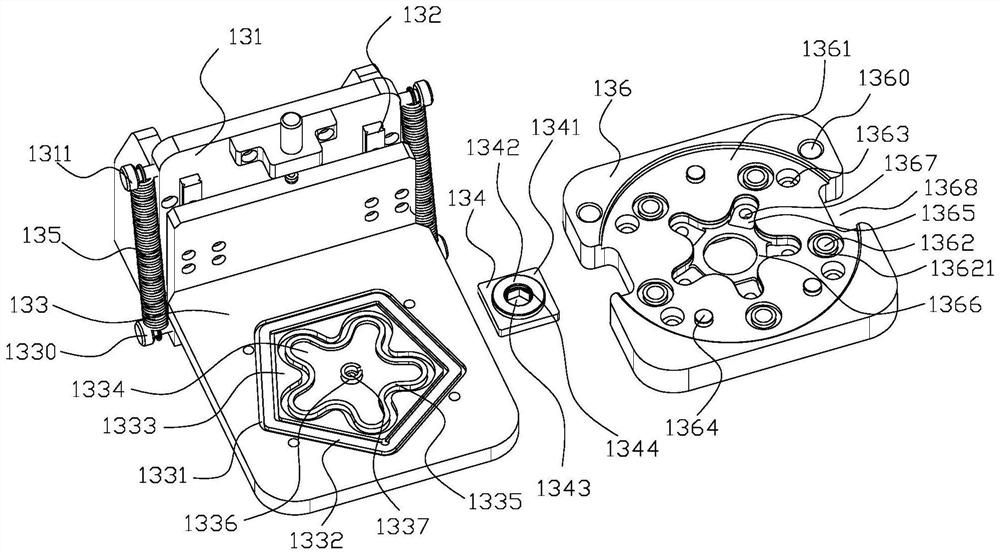

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

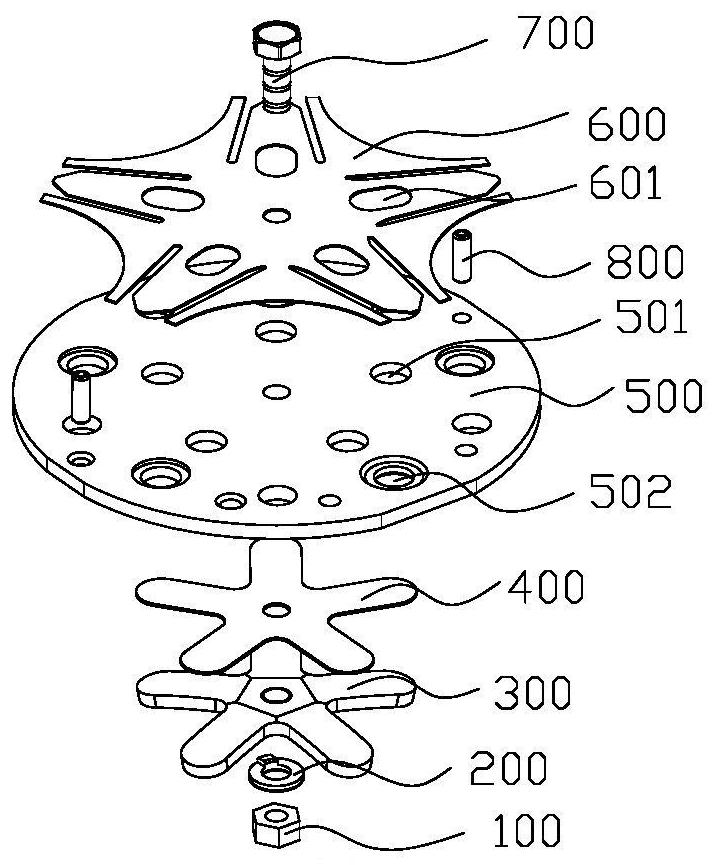

[0022] Such as figure 2 As shown, the valve controller of the present invention includes nut 100, shrapnel 200, exhaust sheet 300, exhaust baffle 400, substrate 500, suction sheet 600 and bolt 700 from bottom to top; 100 is conveyed to the indexing plate device 1, the shrapnel 200 is conveyed to the top of the nut 100 through the shrapnel feeding device, and the exhaust sheet 300 is conveyed to the top of the shrapnel 200 through the exhaust sheet feeding device. The exhaust sheet 300 is in the shape of an arc-shaped five-pointed star shape, and the five corners of the exhaust sheet 300 are all inclined downward; the center of the exhaust sheet 300 is provided with an exhaust sheet assembly through hole; the exhaust flap 400 is transported to the exhaust sheet 300 by the exhaust flap feeding device Above, the exhaust flap 400 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com