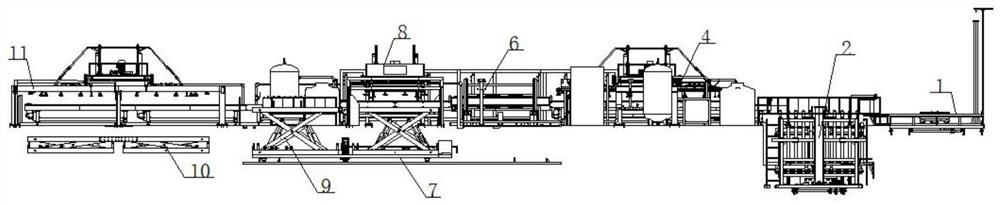

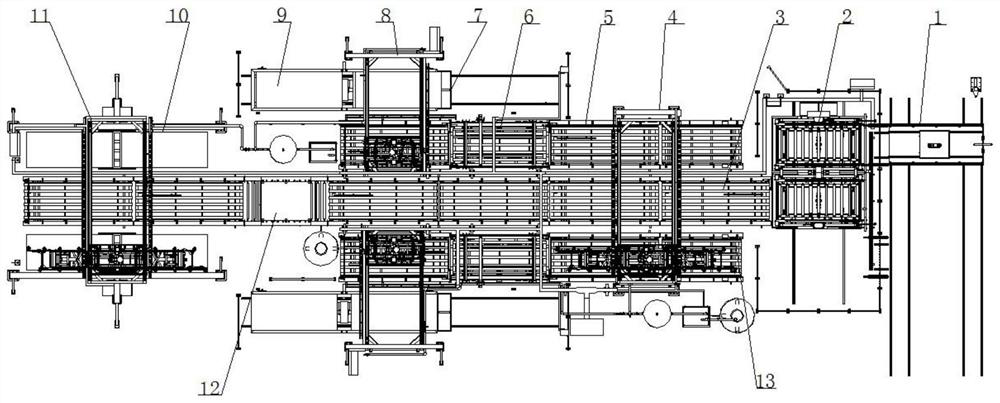

Three-line combined production line with demolding function

A production line and functional technology, applied in the direction of manufacturing tools, unloading devices, ceramic molding machines, etc., can solve the problems of impurities in templates and product boards, increased production costs, and low practicability, achieving low manufacturing costs and high practicability , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

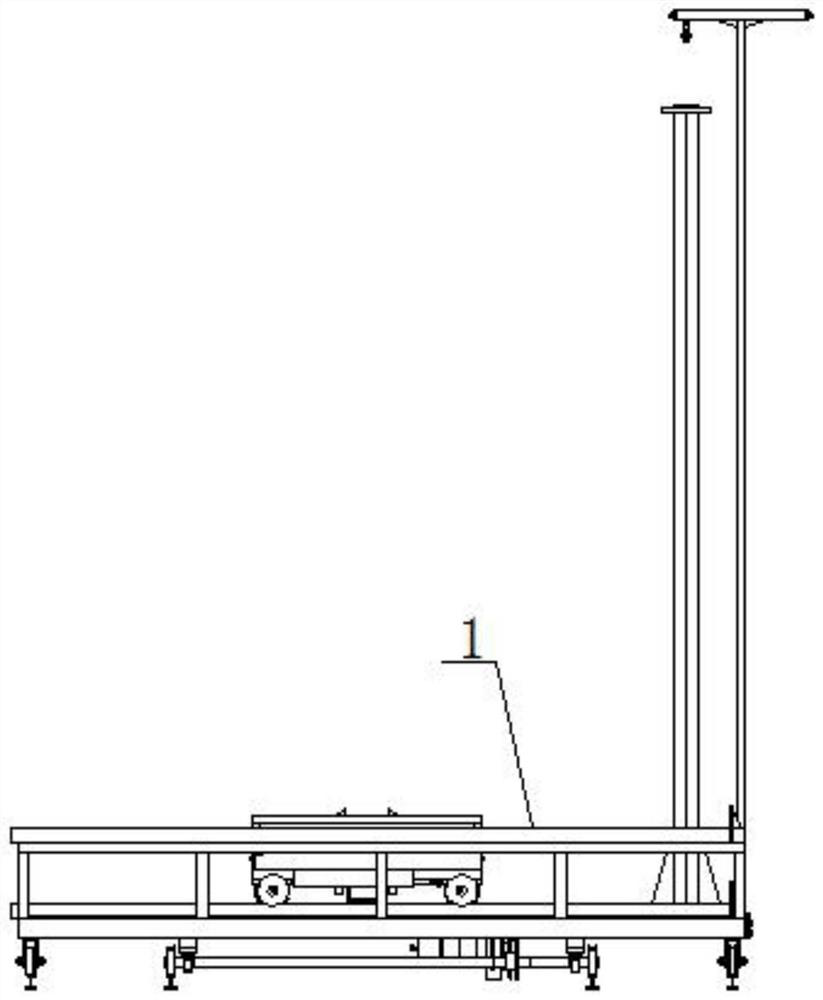

[0026] Embodiment 1, Conveying Line A 3, Conveying Line B 5, and Conveying Line C 13 drive the sprocket drive line belt through the reduction motor to provide power for the rollers, and the electric shuttle 1 and the elevator shuttle 7 drive the track through the motor and the sprocket The rollers walk on the track, the unloader 2 drives the track rollers to walk on the track through the motor and the sprocket, the hydraulic station provides power to drive the hoist to move up and down, and the motor and sprocket on the column of the unloader 2 drive the roller to rotate to provide the formwork Launch power.

[0027] Implementation column 2, three-station double-sucker machine 4, three-station double-sucker machine with widened legs 11, double-station single-sucker machine 8 is driven by a motor, and the template and product board are picked and placed by the vacuum station and vacuum suction cup, and the flap is turned The machine 6 is driven by the motor to realize the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com