Cable winding roller capable of automatically winding cable

A technology for winding rollers and cables, applied in cable laying equipment and other directions, can solve the problems of large volume, inconvenient application, increased equipment cost investment, etc., and achieve the effect of convenient construction, avoiding looseness, and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

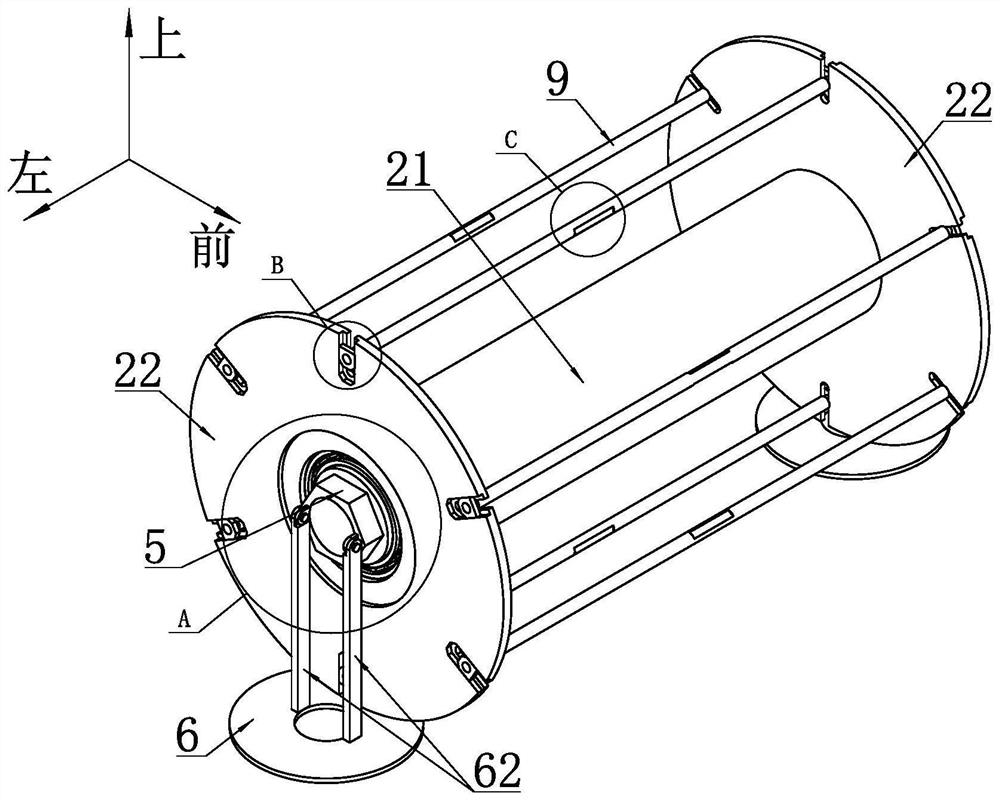

[0043] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

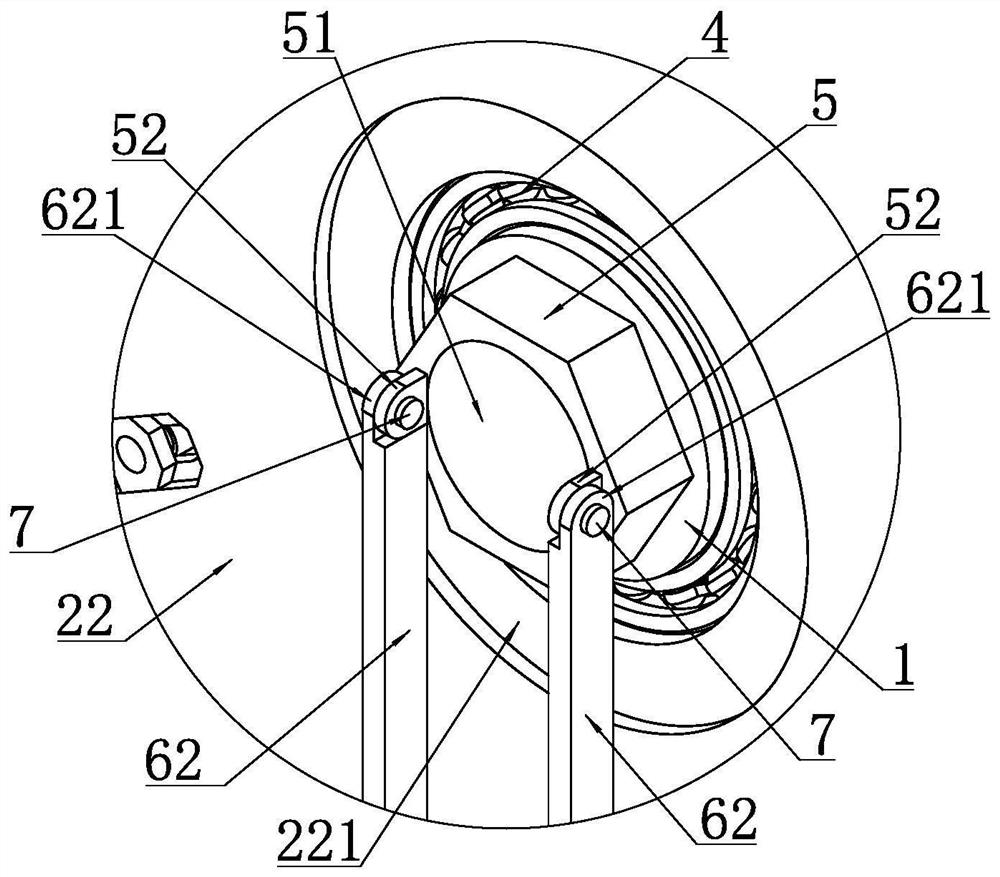

[0044] Such as figure 1 , Figure 5 and Figure 6 As shown, a cable winding roller capable of autonomously winding cables includes an inner cylinder 1 and an outer cylinder 2 sleeved outside the inner cylinder 1, and the inner cylinder 1 and the outer cylinder 2 are located between the inner cylinder 1 and the outer cylinder 2. The left and right ends of the inner cylinder 1 are respectively provided with bearing assemblies 4 , and the outer cylinder 2 can rotate around the rotation axis relative to the inner cylinder 1 .

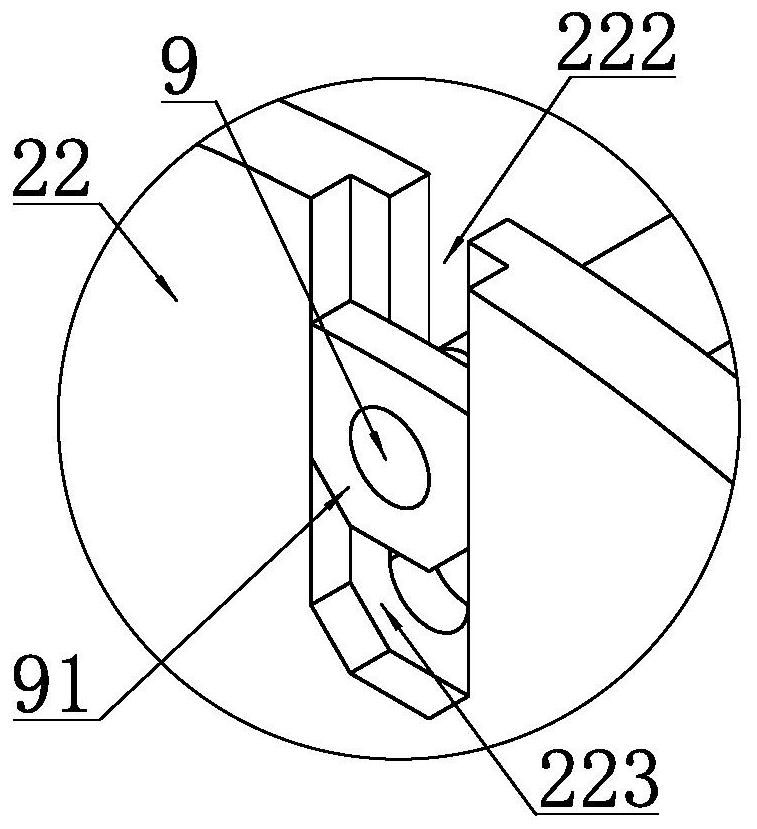

[0045] The outer cylinder 2 includes a cylindrical outer cylinder body 21, and two ends of the outer cylinder body 21 are fixedly provided with baffles 22 with circular outer edges. Preferably, the outer cylinder 21 and the baffle 22 adopt an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com