A bearing holder and a prefabricated large roller bearings

A technology for bearing cages and roller bearings, applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of complex processing, high strength requirements, expensive casting materials, etc., achieve high strength, meet strength requirements, The effect of light and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

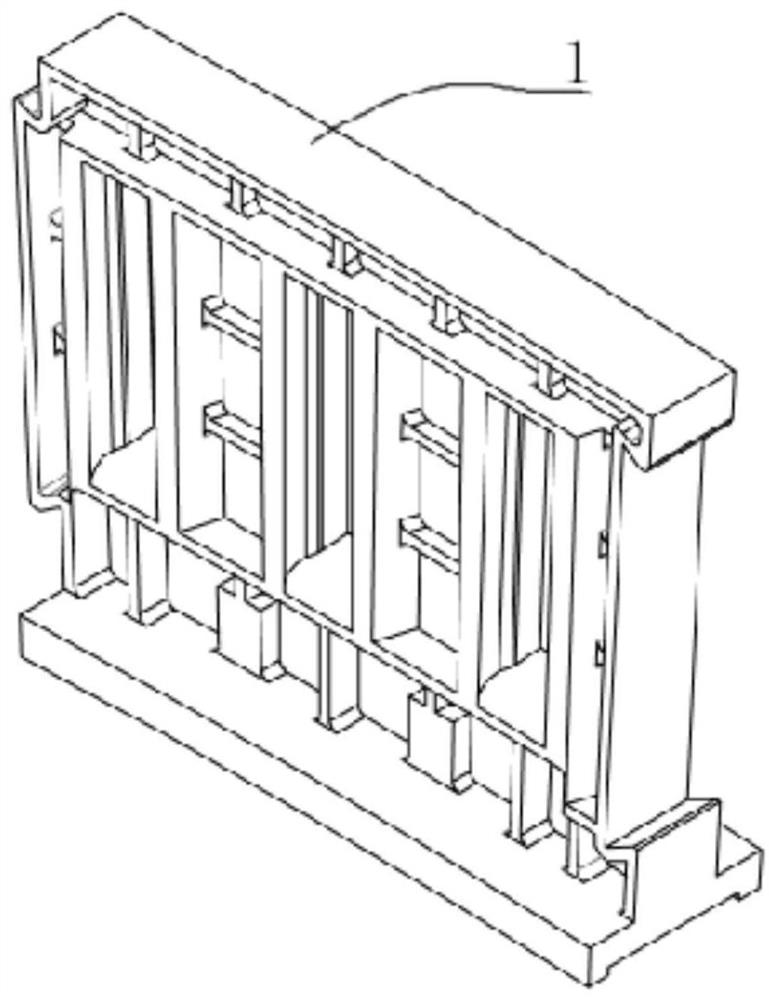

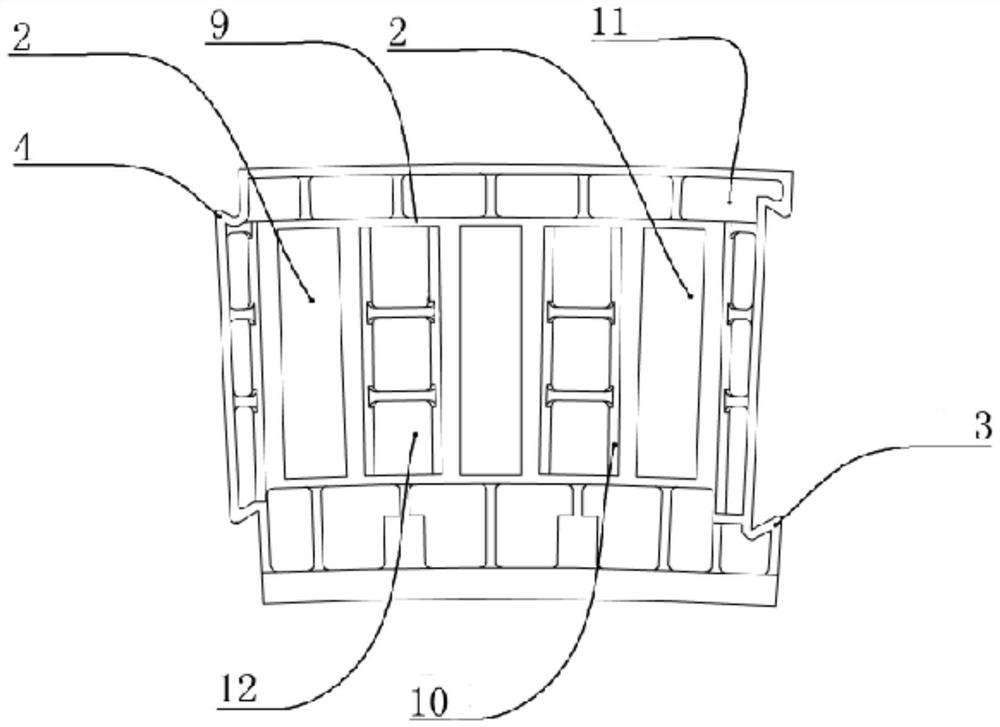

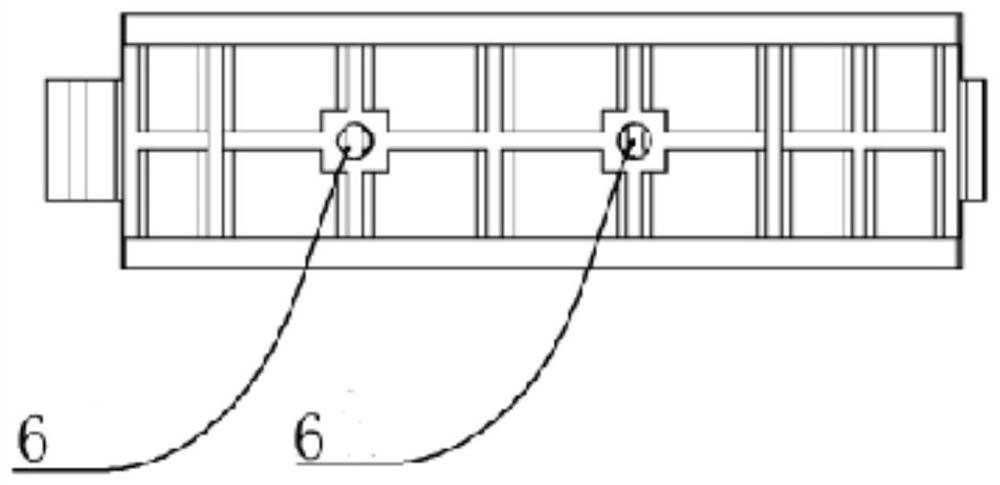

[0030] like Figure 1-5As shown, a bearing cage is shown, the cage is an annular cage, which is formed by splicing a plurality of identical cage modules 1 connected by end-to-end clamping, and at least one cage module 1 is distributed along the circumferential direction on the cage module 1. Pocket 2. The holder module 1 is provided with a card slot on one side and a clip 4 on the other side. When connecting, the card slot of one holder module 1 is fitted with the card bar 4 on the other holder module 1, and the connection is made. into a complete ring to form the bearing cage. The clamping groove is a dovetail groove 3 with a gradually narrowed opening, and the clamping strip 4 is a clamping strip 4 that matches the shape of the dovetail groove 3, and the clamping groove and the clamping strip 4 are clamped from the axial direction of the bearing. It is fixed and limited by the narrow end of the dovetail groove 3 to form a circumferential anti-dropping structure. The inner...

Embodiment 2

[0034] An assembled large roller bearing equipped with the bearing cage described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com