Eddy-current ultrasonic nondestructive testing device for automobile fuel seamless steel tubes

A seamless steel pipe, non-destructive testing technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve poor detection results, affect product quality, and installation costs High-level problems, to achieve efficient classification collection and marking operations, improve accuracy and detection efficiency, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, and specific implementation methods will be given.

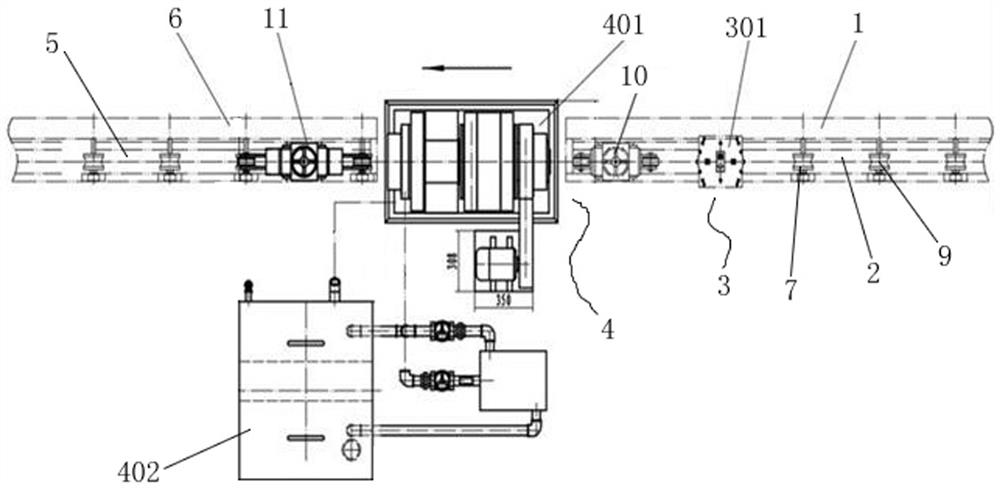

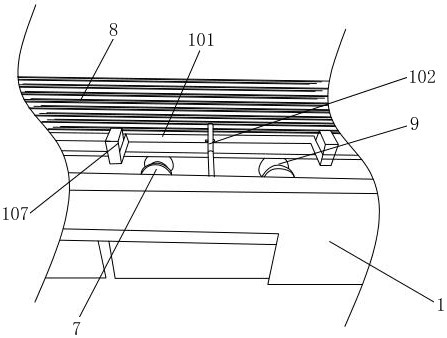

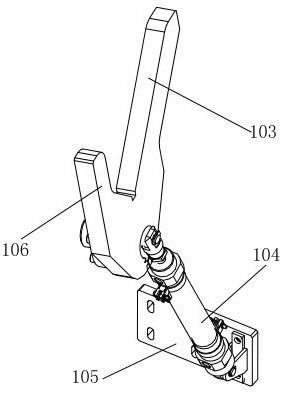

[0022] Such as figure 1 As shown in the figure, the eddy current ultrasonic non-destructive testing device for automobile fuel oil seamless steel pipes includes a feeding platform, a front raceway, an eddy current flaw detection device, an ultrasonic flaw detection device, a rear raceway, a material discharging and sorting device, and a For the control system for controlling feeding, unloading, steel pipe transmission, sorting, and defect alarm, the front raceway and the rear raceway are composed of rollers arranged at intervals, and the rollers are provided with grooves for the passage of fuel stainless steel pipes. A marking device is installed on the sorting device to mark unqualified steel pipes. The eddy current flaw detection device includes an eddy current rotating probe. To detect natural defects in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com