Dust filter bag for vacuuon cleaner

A technology for dust filter bags and vacuum cleaners, applied in the direction of vacuum cleaners, suction filters, applications, etc., can solve problems such as expensive solutions, and achieve the effect of large resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

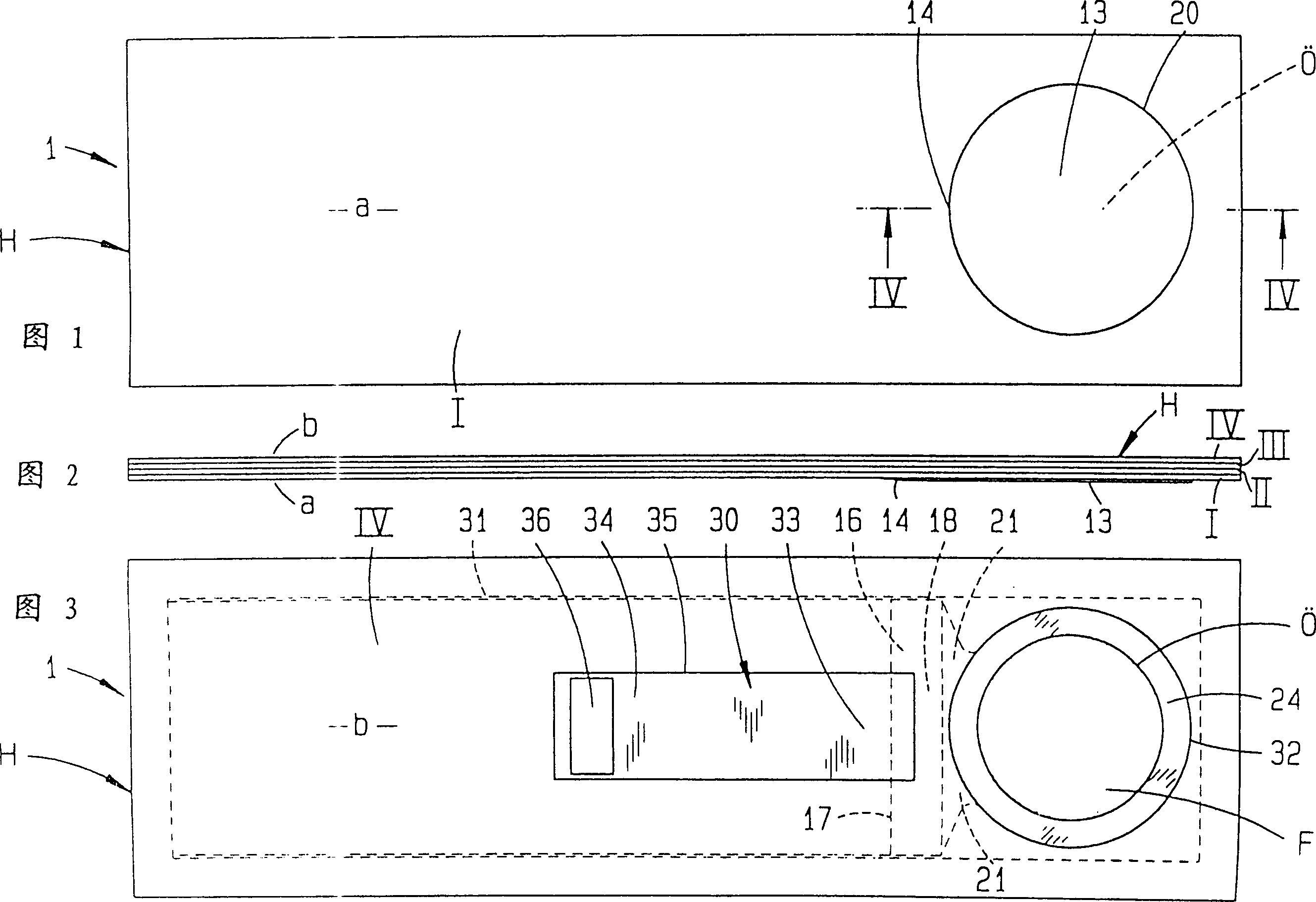

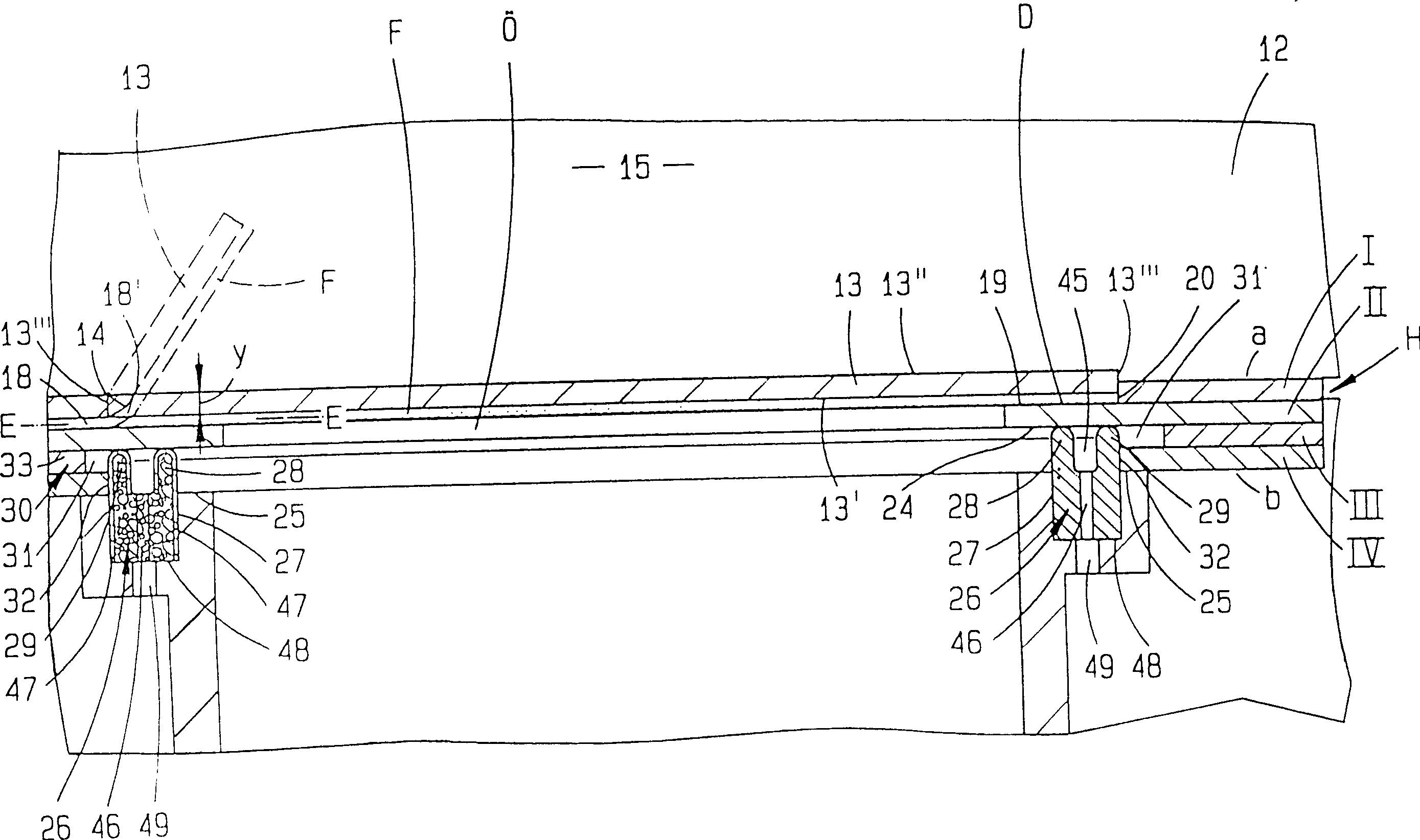

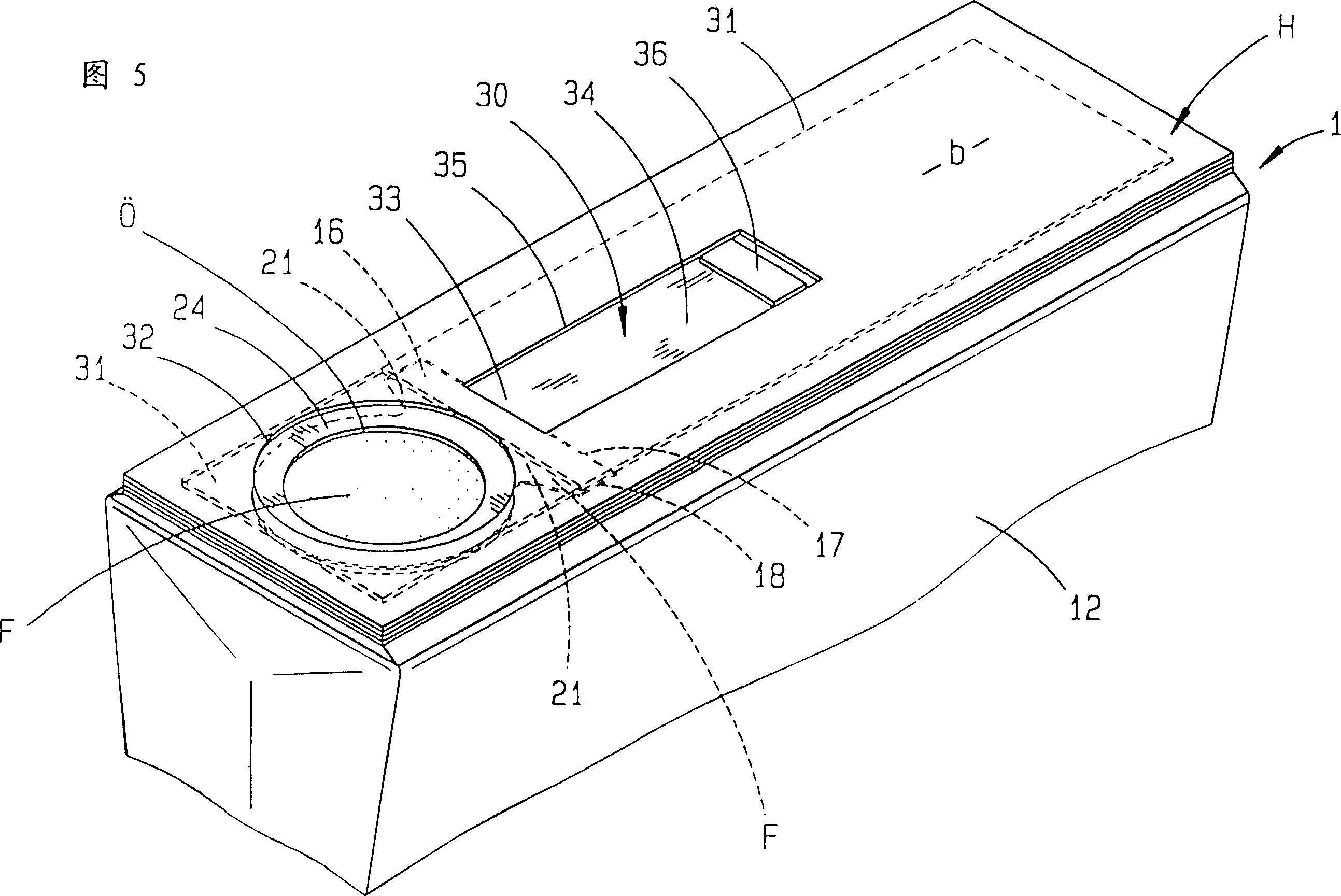

[0043] The dust filter bag 1 depicted in the figures is a so-called single-use or disposable bag.

[0044] For this purpose, the installation chamber 2 of the vacuum cleaner 3 is used for an exchangeable dust filter bag 1 . It can be seen from Fig. 23 that the vacuum cleaner may involve a hand-held vacuum cleaner. A blower 4 in the form of a motor / blower assembly, electrically driven by a power supply or a battery, is housed in a chamber 5 which is detachable from the housing 2 or is separate therefrom. The support wall of the dust filter bag 1 , which is indicated as air-permeable, is denoted by 6 in the figure. Mounted on the support wall 6 is a tuyere 7 passing through it, the tuyere 7 being connected to the suction channel 8 . The suction channel 8 communicates with the suction nozzle 9 . Below the blower 4 there is an upwardly open deflector 10 . There is an exhaust air filter 11 below the deflector 10 . The air outlet is connected to it.

[0045] The connecting sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com