An airflow cascade enhanced vibrating screening system

A vibrating sieving and vibrating sieve technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low recovery rate of fine particles, unfavorable fine particle stratification, sieving, and reduced product quality, etc., to achieve Enhance the ability of perforation layering and touch screen through the screen, avoid uneven screening, and the effect of efficient deep screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

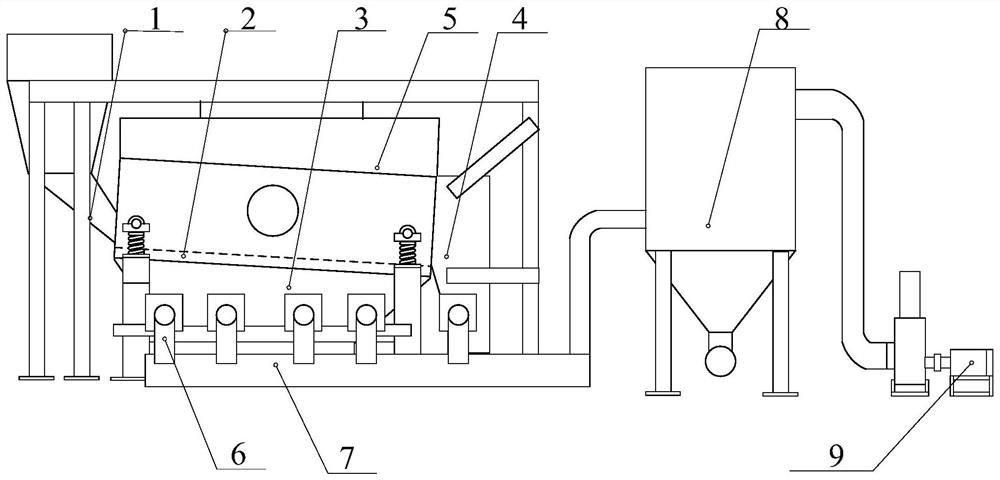

[0020] Such as figure 1 As shown, the air flow cascade enhanced vibrating screening system includes screening components and air induction devices;

[0021] The screening assembly includes a vibrating box and a vibrating screen 2, the upper end of the vibrating box is sealed by a dust cover 5, and the left end is provided with a feeding chute 1;

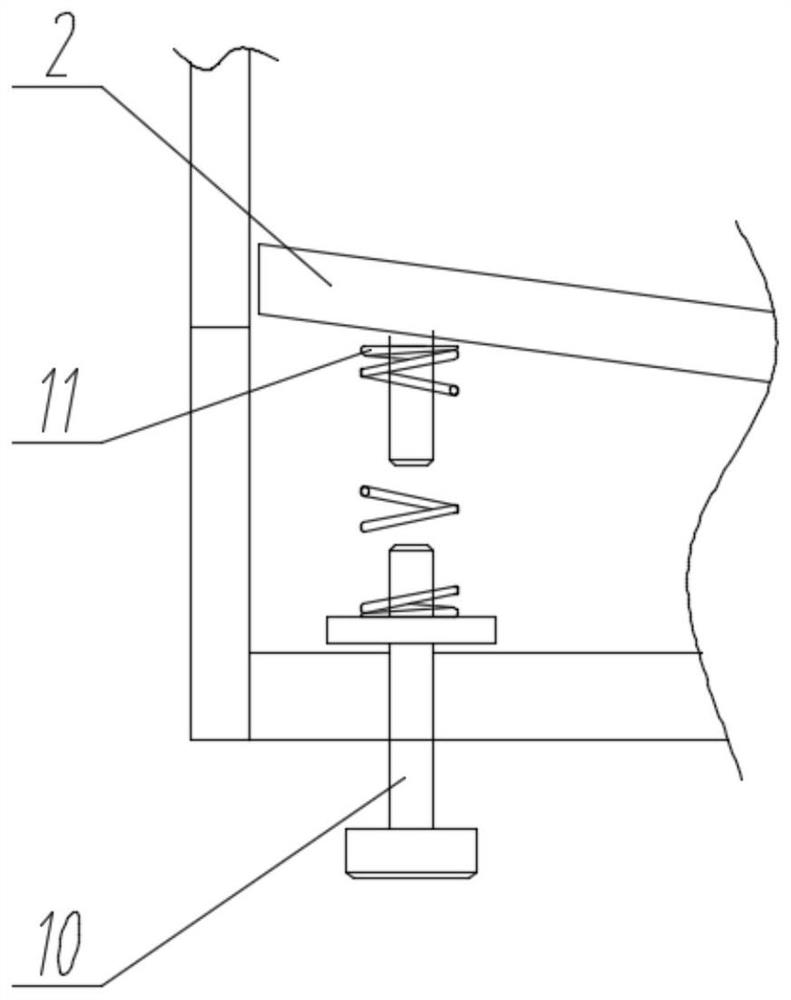

[0022] The vibrating screen 2 is located in the vibrating box, and the material is screened through the vibrating component. The vibrating component can be an eccentric wheel vibrator. The left end of the vibrating screen 2 is lower than the feeding chute 1, and the right end is inclined downward and close to the chute 4 above the screen. , the bottom of the vibrating screen 2 is provided with an under-screen chute 3;

[0023] The air induction device includes an air duct assembly 6 and a main air duct 7. The air duct assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com