Device for poking burrs of oil hole of inner ring of joint bearing

A technology of joint bearings and oil holes, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as high labor costs, asymmetric oil holes, and inapplicability, and reduce human resources and labor costs, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

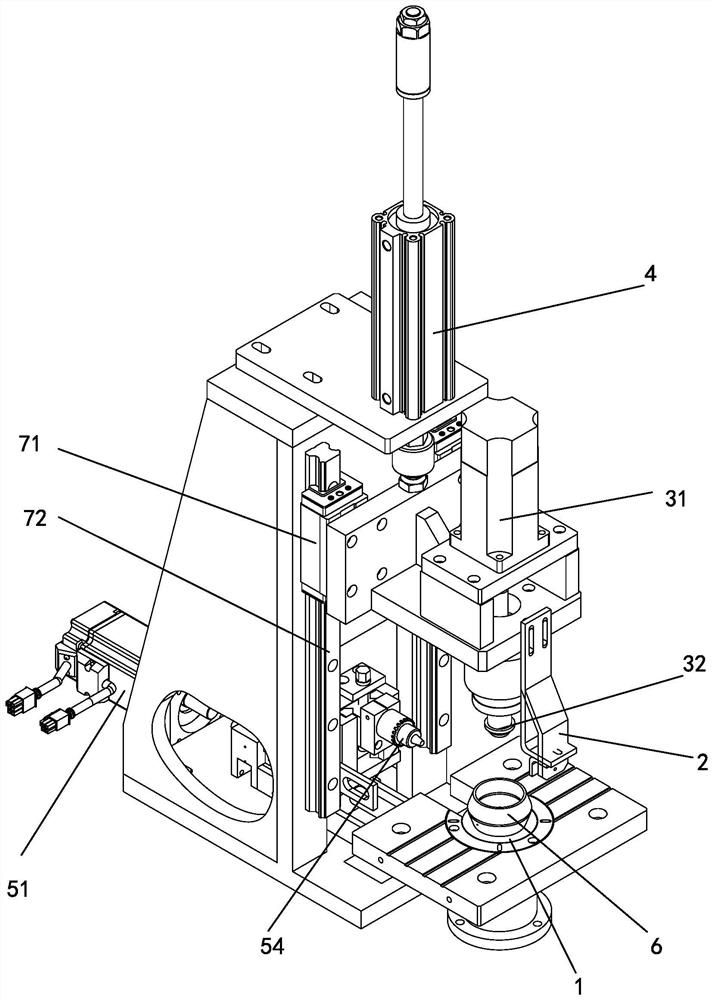

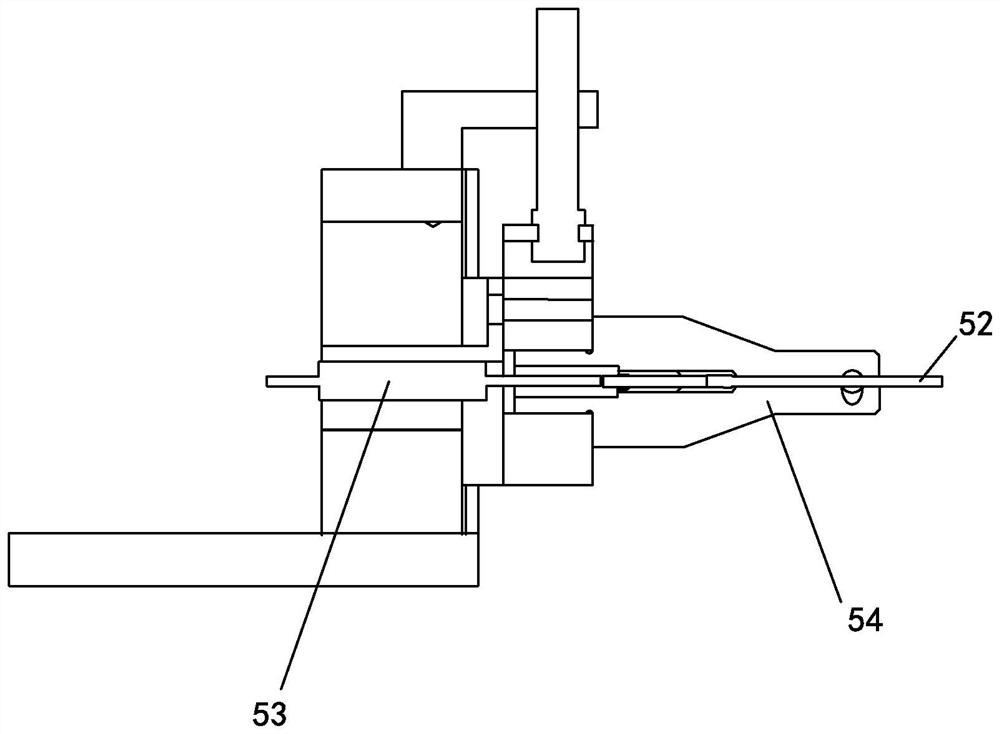

[0015] Examples, see figure 1 with figure 2 As shown, an oil hole deburring device for the inner ring of a joint bearing of the present invention includes a rotating bottom plate 1, an oil hole positioning assembly 2, a rotating drive assembly, a pressing cylinder 4, and a thimble assembly;

[0016] The oil hole positioning component 2 includes a positioning fiber, and the positioning fiber sends the positioning information of the oil hole to the PLC system, and the PLC system determines and controls the rotating drive component. In this embodiment, the positioning fiber is installed in the on the rotary drive assembly.

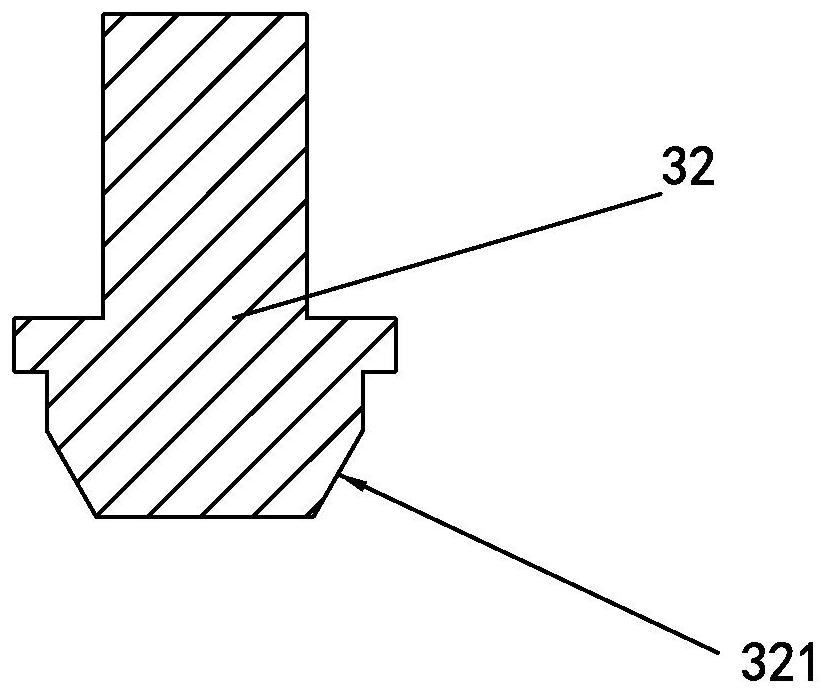

[0017] The rotary drive assembly includes a rotary motor 31 and a pressure head 32, and the pressure head 32 has an inverted tapered surface of revolution 321, such as image 3 As shown, the inverted tapered surface of revolution enables the parts to be quickly positioned to the rotation center of the indenter 32, and the press-down cylinder 4 drives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com