System for dynamically designing fixed size

A technology of dynamic design and sizing, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as calculation errors and production losses, and achieve the effect of improving accuracy and avoiding calculation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

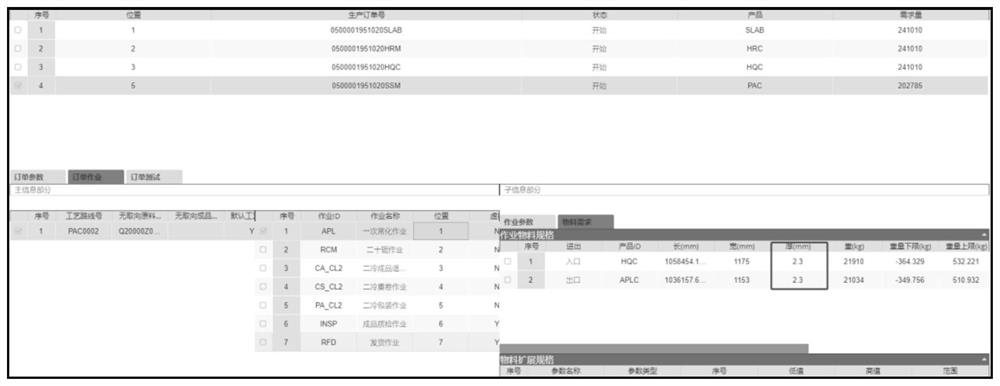

[0148] The internal grade corresponding to an order: S09410;

[0149] The units involved in the thickness measurement are: APL (normalization)-RCM (twenty-roll mill)-CA_CL2 (finished product annealing)-CS_CL2 (recoiling)

[0150] Using the forward-to-back calculation method, the following information is obtained:

[0151] (1) Designated thickness of hot rolling: 2.3mm

[0152] (2) Negative deviation rolling amount: 0

[0153] (3) Order thickness: 0.35

[0154] According to the information in (1)~(3), the final results of each process / unit after calculation are as attached image 3 ~ attached Figure 6 Shown:

[0155] Normalization: entrance thickness 2.3mm, exit thickness 2.3mm;

[0156] Twenty rolls: entrance thickness 2.3mm, exit thickness 0.35mm;

[0157] Finished product annealing: entrance thickness 0.35mm, exit thickness 0.35mm;

[0158] Rewinding: Entrance thickness 0.35mm, exit thickness 0.35mm.

Embodiment 2

[0165] The internal grade corresponding to an order: S12110;

[0166] The passing unit involving width is: APL (normalization)-PL_TCM (acid rolling unit)-CA_CL2 (finished product annealing)-CS_CL2 (heavy coil)

[0167] Using the calculation method from front to back, first obtain the specified width of hot rolling according to the order width:

[0168] (1) Order width: 1237mm;

[0169] (2) Specified width of hot rolling: 1275mm;

[0170] Then according to the above width information, further obtain other width production information:

[0171] (3) APL trimming amount: 0

[0172] (4) PL_TCM necking amount: 4

[0173] (5) PL_TCM trimming amount: 0

[0174] (6) CS_CL2 trimming amount: 34

[0175] According to the information in (1)~(6), calculate the entrance and exit widths of each process / unit in turn, and the final expanded results are as attached Figure 8 ~ attached Figure 11 Shown:

[0176] Normalization: entrance width 1275mm, exit width 1275mm;

[0177] Acid r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com