Plate cutting device for automobile production and machining

A technology for cutting devices and automobiles, which is applied in the direction of shearing devices, metal processing equipment, and accessories of shearing machines. It can solve problems such as the inability to adjust the orientation of cutting devices and affect the use of equipment, and achieve convenient sealing and cutting processing and convenient collection. Handling, Ease of Use Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

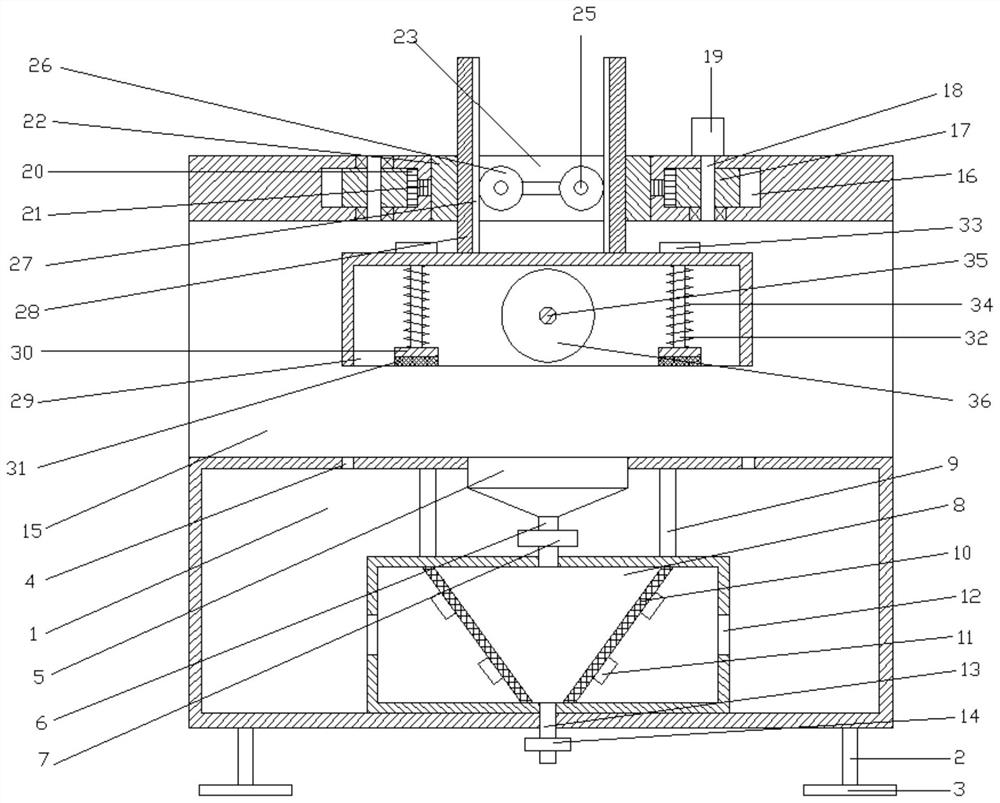

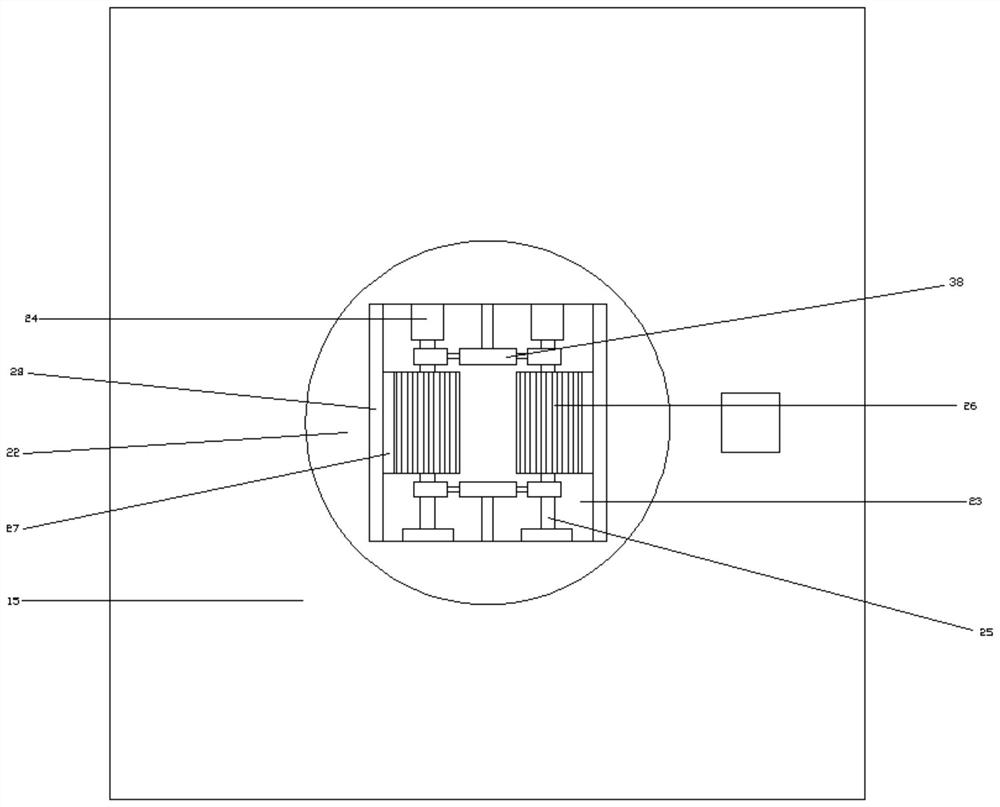

[0026] refer to Figure 1~4 , in an embodiment of the present invention, a plate cutting device for automobile production and processing includes a support frame 1, support legs 2 are fixedly installed at the four corners of the lower side of the support frame 1, and support blocks 3 are fixedly installed on the lower side of the support leg 2, which can Effectively support the entire device, the top of the support frame 1 is provided with a dust cover 5, and the support frame 1 outside the dust cover 5 is provided with an annular connection opening 4, which can facilitate the connection between devices, thereby facilitating the use of the device , the lower side of the dust collection cover 5 is equipped with a dust suction pipe 6, a dust suction pump 7 is installed on the dust suction pipe 6, and a dust collection chamber 8 is installed on the bottom of the dust collection pipe 6, which is used to store filtered impurities and collect dust. The four corners on the upper side...

Embodiment 2

[0031] The difference from Embodiment 1 is that: the bottom of the left and right ends of the sealing cover 29 is provided with an extrusion plate 30, the friction pad 31 is installed on the lower side of the extrusion plate 30, and the front and rear ends of the upper side of the extrusion plate 30 are fixedly installed with connection pads. Rod 32, the upper side of connecting rod 32 is fixedly installed limit block 33, and limit block 33 is installed on the upper side of sealing cover 29, and spring 34 is installed on the connecting rod 32 that is positioned at sealing cover 29 inside, and sealing cover 29 is moving downwards. During the process, the extrusion plate 30 and the friction pad 31 will clamp the automobile sheet to be processed, which can facilitate the cutting of the automobile sheet and facilitate the use of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com