Processing technology and processing device of ceramic ferrule

A ceramic ferrule and processing technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problem of not being able to meet the standard of ≤ 0.1°, and achieve the convenience of batch processing, cost reduction, clamping force optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

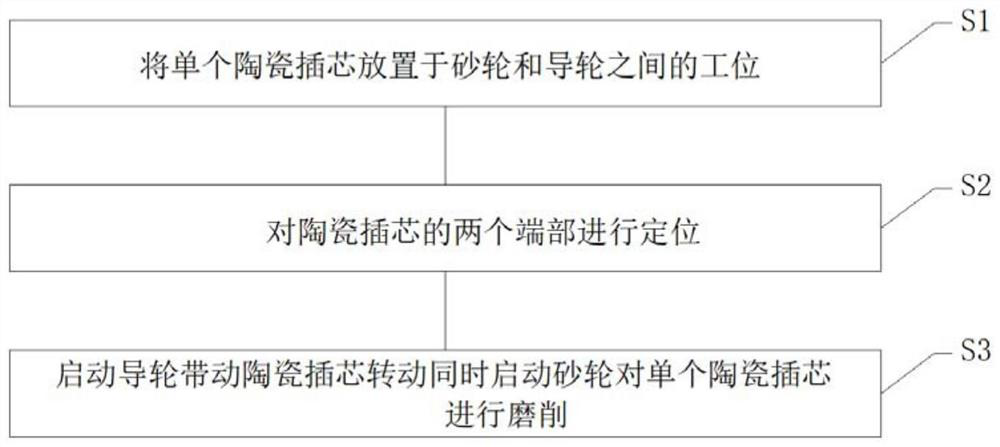

[0040] refer to figure 1 and figure 2 As shown, this embodiment discloses a processing technology for a ceramic ferrule of an optical fiber connector. The ceramic ferrule 3 is provided with an inner hole 3.1, and the inner hole 3.1 extends to both ends of the ceramic ferrule. The processing of the ceramic ferrule 3 The process includes the following steps:

[0041] Step S1, placing a single ceramic ferrule 3 at the station between the grinding wheel 1 and the guide wheel 2, since the ceramic ferrule is processed individually, that is, the size of the grinding wheel 1 and the guide wheel 2 can be the same, which is mainly the same as that of the ceramic ferrule. Ferrule fit.

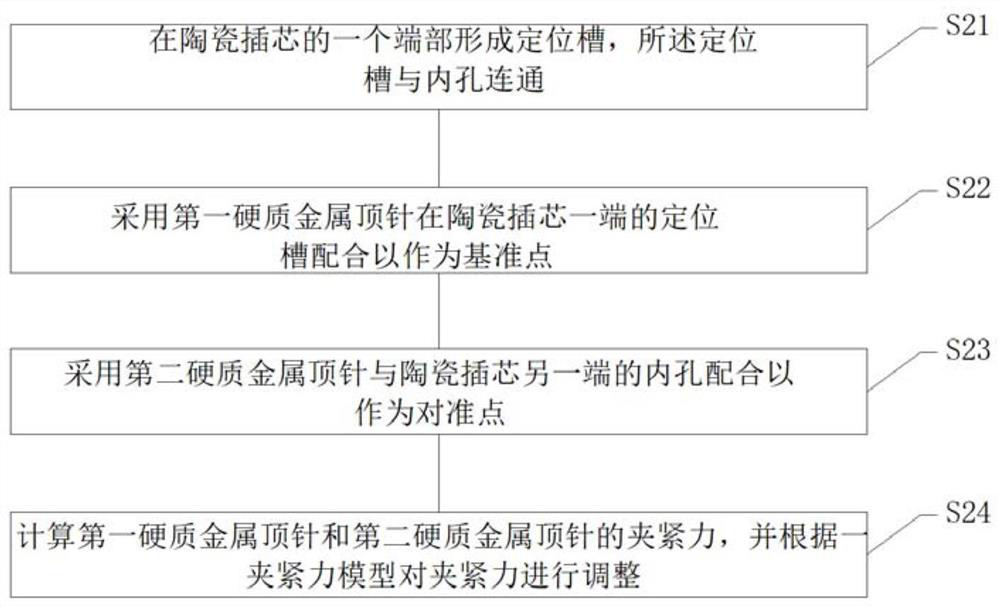

[0042] Step S2: Position the two ends of the ceramic ferrule 3, and use the end positioning method to replace the steel wire positioning method in the prior art, which solves the traditional unavoidable bending of the steel wire and the inner gap between the steel wire and the ferrule. hole clearance ...

Embodiment 2

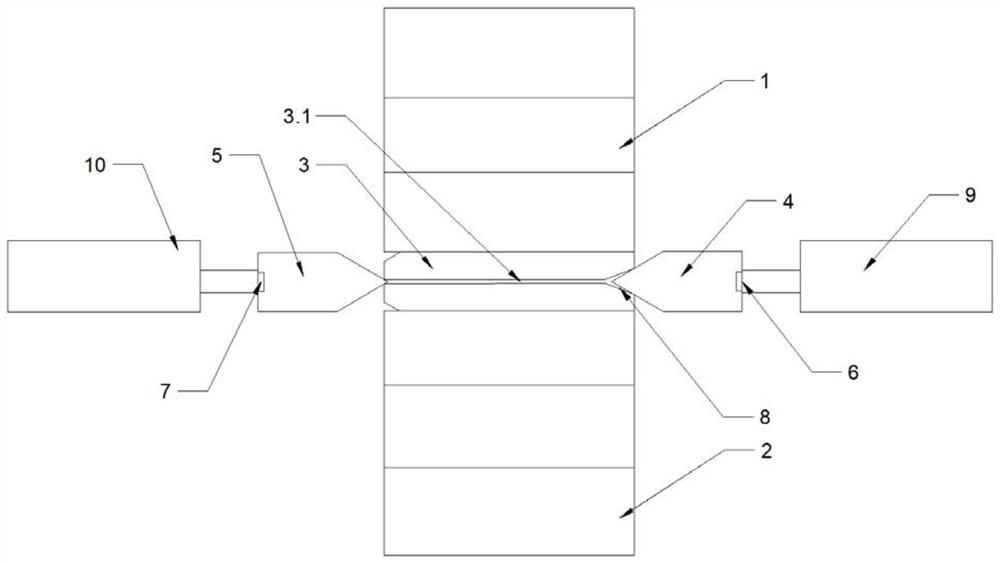

[0054] refer to image 3 As shown, this embodiment also provides a processing device for realizing the processing of the ceramic ferrule of the optical fiber connector, including a grinding wheel 1 and a guide wheel 2, and also includes a positioning device. The positioning device includes a first hard metal thimble 4 and a second hard metal thimble. Hard metal thimble 5, the first hard metal thimble 4 cooperates with the positioning groove 8 at one end of the ceramic ferrule 3, the second hard metal thimble 5 cooperates with the inner hole 3.1 at the other end of the ceramic ferrule 3, the first hard metal thimble The thimble 4 and the second hard metal thimble 5 exert a clamping force on both ends of the ceramic ferrule 3 during the grinding process of the ceramic ferrule 3 for positioning.

[0055] As a preference, the processing device of this embodiment further includes a first power unit 9 connected to the first hard metal thimble 4, and / or a second power unit 10 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com