A gasket inner hole grinding device for metal processing

A metal processing and washer technology, used in grinding drive devices, metal processing equipment, grinding workpiece supports, etc., can solve the problems of low work efficiency, labor consumption, and easy residual metal debris, and achieve improved efficiency and adjustment effect. Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

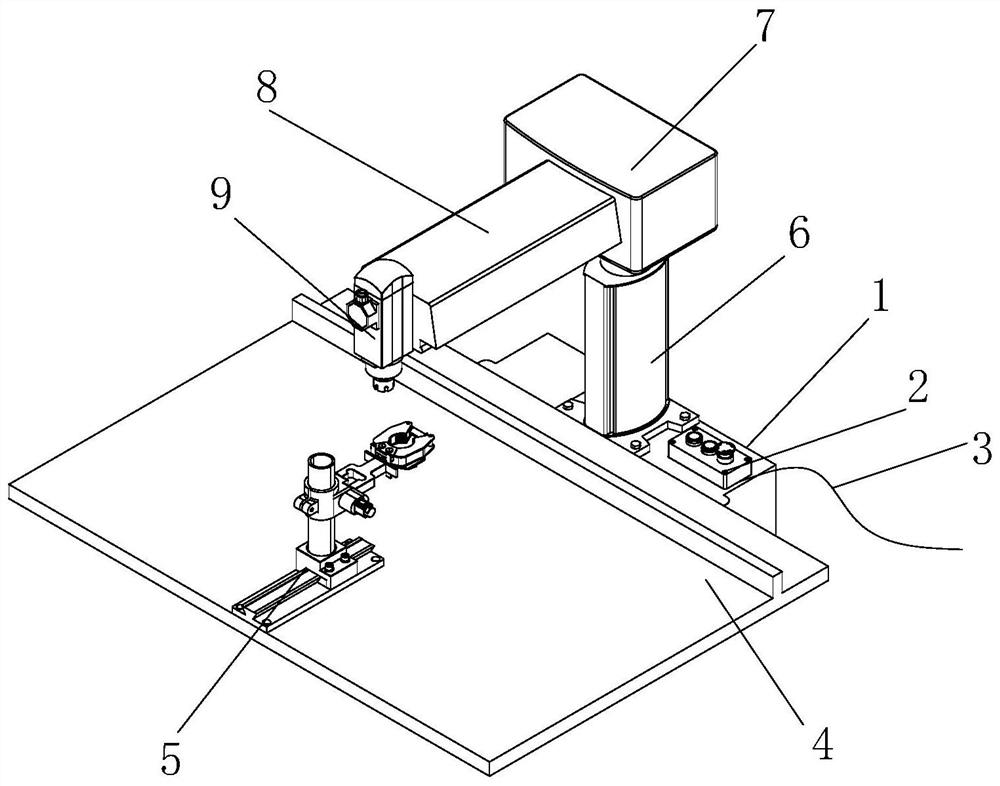

[0029] see figure 1 , the present invention provides a gasket inner hole grinding device for metal processing through improvement, including a base 1, a controller 2 is installed at the top right end of the base 1, a power cord 3 is provided at the bottom right end of the controller 2, and the base The front end of the top of the base 1 is welded and fixed to the processing plate 4, the middle part of the top end of the base 1 is provided with a first cylinder 6, the top of the first cylinder 6 is connected to the fixed block 7, the middle part of the front end of the fixed block 7 is welded with a support arm 8, and the front end of the support arm 8 The surface is connected with the grinding head 9, and the grinding head 9 is electrically connected with the controller 2, and the middle part of the front end of the top of the processing plate 4 is equipped with an auxiliary stabilizing device 5.

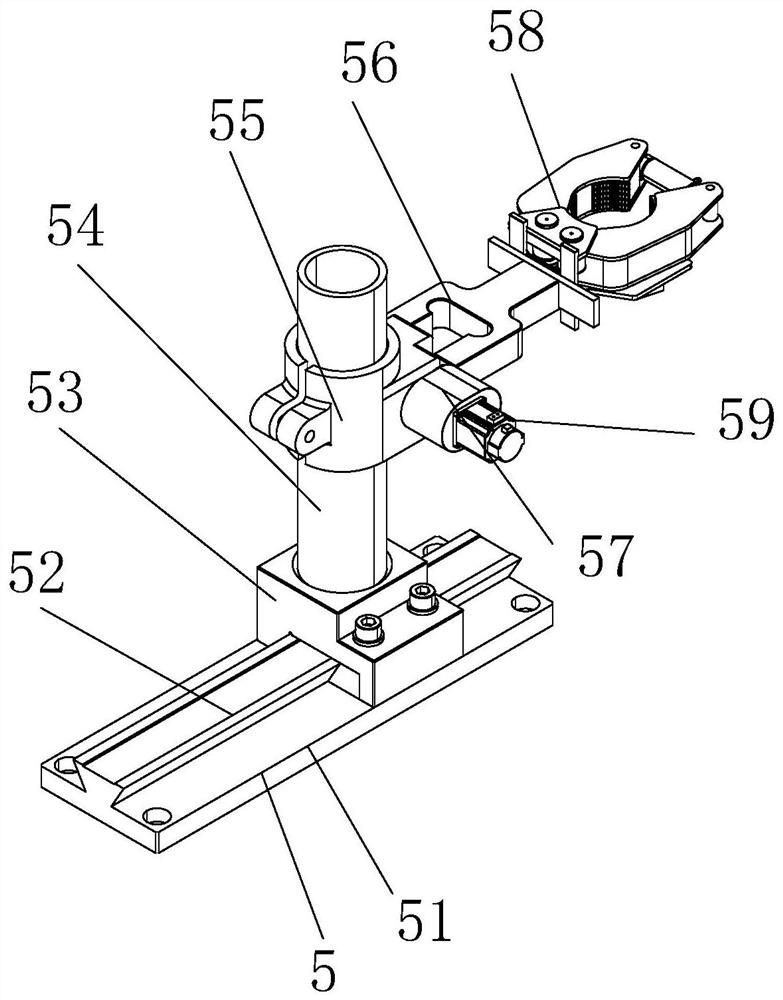

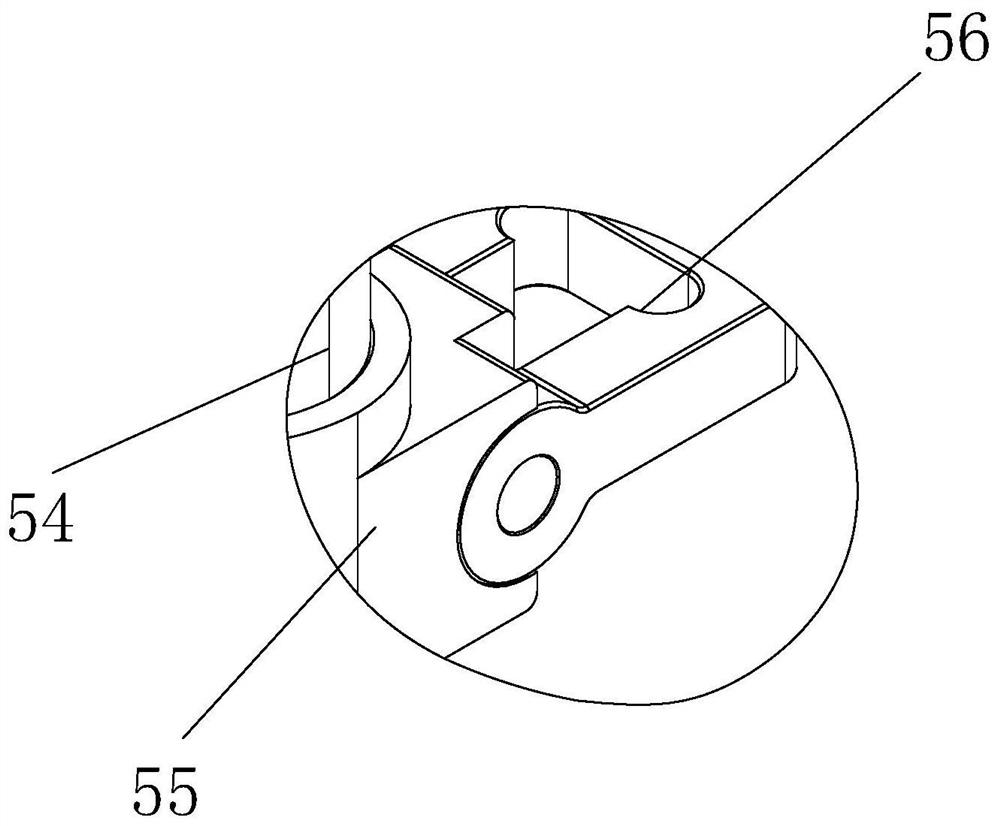

[0030] see figure 2 and image 3 , the present invention provides a gasket i...

Embodiment 2

[0034] The present invention provides a gasket inner hole grinding device for metal processing through improvement. The four ends of the base 51 are provided with screw holes, and the inner four ends are locked into the screw holes and the processing plate 4 by external bolts. The connection is stable and the fixing effect is good; the surface of the outer diameter of the pillar 54 is smooth, and the height is smaller than the height of the first cylinder 6, which is moderate in size and convenient for adjustment; Auxiliary manual processing operations.

[0035] The present invention provides a gasket inner hole grinding device for metal processing through improvement, and its working principle is as follows;

[0036] First, when the device needs to be used, first place the device at the position where it needs to be used, and the position must be horizontal, and then connect the power cord 3 to an external power supply to provide the required power for the device to work , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com